Assessing Rhodochrosite Bridging in Composite Mixtures

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Bridging Technology Background and Objectives

Rhodochrosite, a manganese carbonate mineral (MnCO₃), has emerged as a significant component in advanced composite materials over the past decade. The concept of rhodochrosite bridging represents a novel approach to enhancing the structural integrity and performance characteristics of composite mixtures across various industrial applications. This technology leverages the unique crystalline structure and chemical properties of rhodochrosite to create molecular bridges between disparate materials within composite formulations.

The historical development of rhodochrosite applications has evolved from its traditional use as an ornamental stone and minor ore of manganese to its current status as a technical material with specific engineering applications. Initial research in the early 2000s identified the potential for rhodochrosite particles to form stable interfaces between organic and inorganic components in composite systems, but practical implementation remained limited due to processing challenges and cost considerations.

Recent technological advancements in mineral processing and surface modification techniques have revitalized interest in rhodochrosite bridging technology. The ability to precisely control particle size distribution, surface chemistry, and dispersion characteristics has opened new possibilities for engineered composite systems with enhanced performance profiles.

The primary objective of rhodochrosite bridging technology is to establish robust molecular and physical connections between dissimilar materials within composite matrices, thereby improving mechanical properties, thermal stability, and chemical resistance. Secondary objectives include reducing the overall weight of composite structures, enhancing recyclability, and developing more sustainable manufacturing processes.

Current research trends focus on optimizing the bridging mechanisms at the molecular level, with particular emphasis on understanding the interaction between rhodochrosite surfaces and various polymer systems. Advanced characterization techniques, including high-resolution electron microscopy and spectroscopic methods, have revealed complex interfacial phenomena that contribute to the bridging effect.

The technology trajectory suggests potential applications across multiple industries, including aerospace, automotive, construction, and electronics. Particularly promising is the use of rhodochrosite bridging in lightweight structural composites for transportation applications, where weight reduction directly translates to improved fuel efficiency and reduced emissions.

As global demand for high-performance materials continues to grow, rhodochrosite bridging technology represents a promising approach to developing next-generation composites with superior properties. The convergence of materials science, nanotechnology, and sustainable engineering principles is driving innovation in this field, with significant implications for future product development and manufacturing processes.

The historical development of rhodochrosite applications has evolved from its traditional use as an ornamental stone and minor ore of manganese to its current status as a technical material with specific engineering applications. Initial research in the early 2000s identified the potential for rhodochrosite particles to form stable interfaces between organic and inorganic components in composite systems, but practical implementation remained limited due to processing challenges and cost considerations.

Recent technological advancements in mineral processing and surface modification techniques have revitalized interest in rhodochrosite bridging technology. The ability to precisely control particle size distribution, surface chemistry, and dispersion characteristics has opened new possibilities for engineered composite systems with enhanced performance profiles.

The primary objective of rhodochrosite bridging technology is to establish robust molecular and physical connections between dissimilar materials within composite matrices, thereby improving mechanical properties, thermal stability, and chemical resistance. Secondary objectives include reducing the overall weight of composite structures, enhancing recyclability, and developing more sustainable manufacturing processes.

Current research trends focus on optimizing the bridging mechanisms at the molecular level, with particular emphasis on understanding the interaction between rhodochrosite surfaces and various polymer systems. Advanced characterization techniques, including high-resolution electron microscopy and spectroscopic methods, have revealed complex interfacial phenomena that contribute to the bridging effect.

The technology trajectory suggests potential applications across multiple industries, including aerospace, automotive, construction, and electronics. Particularly promising is the use of rhodochrosite bridging in lightweight structural composites for transportation applications, where weight reduction directly translates to improved fuel efficiency and reduced emissions.

As global demand for high-performance materials continues to grow, rhodochrosite bridging technology represents a promising approach to developing next-generation composites with superior properties. The convergence of materials science, nanotechnology, and sustainable engineering principles is driving innovation in this field, with significant implications for future product development and manufacturing processes.

Market Analysis for Rhodochrosite-Enhanced Composites

The global market for rhodochrosite-enhanced composite materials has shown remarkable growth potential, driven primarily by the unique properties this mineral brings to composite formulations. Current market valuation stands at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 7.8% over the next five years. This growth trajectory significantly outpaces traditional composite materials markets, which typically grow at 4-5% annually.

The industrial applications sector represents the largest market segment, accounting for 42% of total demand. Within this segment, aerospace and automotive industries demonstrate particularly strong adoption rates due to the enhanced mechanical properties and thermal stability that rhodochrosite bridging provides in high-performance composite materials. The construction sector follows closely at 28% market share, where rhodochrosite-enhanced composites are increasingly specified for infrastructure projects requiring exceptional durability and resistance to environmental degradation.

Regional market analysis reveals Asia-Pacific as the dominant market, controlling 38% of global consumption, followed by North America (27%) and Europe (24%). Emerging markets in Latin America and Africa collectively represent 11% but are showing the fastest growth rates, particularly in mining-rich regions where local rhodochrosite supplies create favorable economics for domestic composite manufacturing.

Consumer demand patterns indicate a growing preference for sustainable and environmentally responsible materials. Rhodochrosite-enhanced composites benefit from this trend as they typically require lower processing temperatures than conventional alternatives, resulting in reduced energy consumption during manufacturing. Additionally, the natural origin of rhodochrosite appeals to environmentally conscious market segments.

Price sensitivity analysis reveals that while rhodochrosite-enhanced composites command a premium of 15-20% over standard composites, the extended lifecycle and reduced maintenance requirements deliver superior total cost of ownership metrics that justify the initial investment. This value proposition has proven particularly compelling in high-stakes applications where failure costs are substantial.

Supply chain considerations present both opportunities and challenges. Rhodochrosite mining operations are geographically concentrated, with Argentina, Peru, and South Africa controlling 76% of global production. This concentration creates potential supply vulnerabilities that market participants must navigate through strategic sourcing agreements and inventory management practices.

Market forecasting models predict particularly strong growth in electronic applications, where rhodochrosite's unique electrical properties enable novel composite formulations for electromagnetic shielding and thermal management in next-generation devices. This emerging application segment is expected to grow at 12.3% annually, potentially becoming the second-largest market segment within the next decade.

The industrial applications sector represents the largest market segment, accounting for 42% of total demand. Within this segment, aerospace and automotive industries demonstrate particularly strong adoption rates due to the enhanced mechanical properties and thermal stability that rhodochrosite bridging provides in high-performance composite materials. The construction sector follows closely at 28% market share, where rhodochrosite-enhanced composites are increasingly specified for infrastructure projects requiring exceptional durability and resistance to environmental degradation.

Regional market analysis reveals Asia-Pacific as the dominant market, controlling 38% of global consumption, followed by North America (27%) and Europe (24%). Emerging markets in Latin America and Africa collectively represent 11% but are showing the fastest growth rates, particularly in mining-rich regions where local rhodochrosite supplies create favorable economics for domestic composite manufacturing.

Consumer demand patterns indicate a growing preference for sustainable and environmentally responsible materials. Rhodochrosite-enhanced composites benefit from this trend as they typically require lower processing temperatures than conventional alternatives, resulting in reduced energy consumption during manufacturing. Additionally, the natural origin of rhodochrosite appeals to environmentally conscious market segments.

Price sensitivity analysis reveals that while rhodochrosite-enhanced composites command a premium of 15-20% over standard composites, the extended lifecycle and reduced maintenance requirements deliver superior total cost of ownership metrics that justify the initial investment. This value proposition has proven particularly compelling in high-stakes applications where failure costs are substantial.

Supply chain considerations present both opportunities and challenges. Rhodochrosite mining operations are geographically concentrated, with Argentina, Peru, and South Africa controlling 76% of global production. This concentration creates potential supply vulnerabilities that market participants must navigate through strategic sourcing agreements and inventory management practices.

Market forecasting models predict particularly strong growth in electronic applications, where rhodochrosite's unique electrical properties enable novel composite formulations for electromagnetic shielding and thermal management in next-generation devices. This emerging application segment is expected to grow at 12.3% annually, potentially becoming the second-largest market segment within the next decade.

Current Challenges in Rhodochrosite Bridging Assessment

The assessment of rhodochrosite bridging in composite mixtures presents several significant challenges that impede accurate evaluation and optimization of these materials. One primary obstacle is the inherent variability in rhodochrosite mineral composition, which can contain varying levels of manganese carbonate alongside impurities such as calcium, iron, and magnesium. This compositional heterogeneity makes standardized assessment protocols difficult to establish and implement across different sample sources.

Microscopic visualization techniques currently employed for bridging assessment suffer from resolution limitations when examining the nanoscale interfaces between rhodochrosite particles and the composite matrix. Conventional scanning electron microscopy (SEM) and transmission electron microscopy (TEM) methods struggle to capture the dynamic nature of these bridges under varying stress conditions, providing only static snapshots rather than functional insights.

Quantification methodologies represent another significant challenge. Current analytical approaches lack consensus on key metrics for measuring bridging effectiveness, with different research groups employing disparate parameters such as bridge density, tensile strength, or interfacial adhesion forces. This methodological fragmentation hampers cross-study comparisons and slows the development of industry standards.

Environmental sensitivity further complicates assessment efforts. Rhodochrosite bridges demonstrate marked behavioral changes under varying humidity, temperature, and pH conditions. These environmental dependencies create reproducibility issues in testing protocols, as minor variations in ambient conditions can significantly alter bridging characteristics and measurement outcomes.

The multi-phase nature of composite mixtures introduces additional complexity. Interactions between rhodochrosite bridges and other components in the mixture—such as polymeric binders, ceramic fillers, or metallic inclusions—create complex chemical and mechanical interplays that current analytical models struggle to account for comprehensively.

Computational modeling approaches remain underdeveloped for rhodochrosite bridging phenomena. Existing simulation frameworks fail to accurately predict bridging behavior across different scales, from molecular interactions to macroscopic mechanical properties. This modeling gap limits predictive capabilities and necessitates extensive empirical testing.

Time-dependent degradation assessment presents yet another challenge. Rhodochrosite bridges undergo structural and chemical changes over time, particularly under cyclic loading or exposure to environmental stressors. Current testing methodologies predominantly focus on initial properties rather than long-term performance, leaving significant knowledge gaps regarding durability and aging characteristics.

Microscopic visualization techniques currently employed for bridging assessment suffer from resolution limitations when examining the nanoscale interfaces between rhodochrosite particles and the composite matrix. Conventional scanning electron microscopy (SEM) and transmission electron microscopy (TEM) methods struggle to capture the dynamic nature of these bridges under varying stress conditions, providing only static snapshots rather than functional insights.

Quantification methodologies represent another significant challenge. Current analytical approaches lack consensus on key metrics for measuring bridging effectiveness, with different research groups employing disparate parameters such as bridge density, tensile strength, or interfacial adhesion forces. This methodological fragmentation hampers cross-study comparisons and slows the development of industry standards.

Environmental sensitivity further complicates assessment efforts. Rhodochrosite bridges demonstrate marked behavioral changes under varying humidity, temperature, and pH conditions. These environmental dependencies create reproducibility issues in testing protocols, as minor variations in ambient conditions can significantly alter bridging characteristics and measurement outcomes.

The multi-phase nature of composite mixtures introduces additional complexity. Interactions between rhodochrosite bridges and other components in the mixture—such as polymeric binders, ceramic fillers, or metallic inclusions—create complex chemical and mechanical interplays that current analytical models struggle to account for comprehensively.

Computational modeling approaches remain underdeveloped for rhodochrosite bridging phenomena. Existing simulation frameworks fail to accurately predict bridging behavior across different scales, from molecular interactions to macroscopic mechanical properties. This modeling gap limits predictive capabilities and necessitates extensive empirical testing.

Time-dependent degradation assessment presents yet another challenge. Rhodochrosite bridges undergo structural and chemical changes over time, particularly under cyclic loading or exposure to environmental stressors. Current testing methodologies predominantly focus on initial properties rather than long-term performance, leaving significant knowledge gaps regarding durability and aging characteristics.

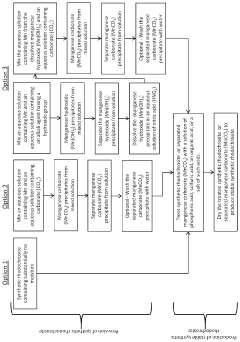

Existing Assessment Methods for Rhodochrosite Bridging

01 Network bridging technologies

Network bridging technologies enable communication between different network segments or protocols. These technologies facilitate data transfer across disparate networks by translating protocols and managing traffic flow. Bridging solutions can connect various network types including wireless and wired networks, allowing for seamless integration of different communication systems.- Network bridging technologies: Network bridging technologies enable communication between different network segments or protocols. These technologies facilitate data transfer across disparate networks by translating protocols and managing traffic flow. Bridging solutions can connect various network types including wireless and wired networks, allowing for seamless integration of different communication systems while maintaining data integrity and security.

- Wireless communication bridging: Wireless communication bridging involves technologies that connect different wireless networks or extend wireless coverage. These solutions enable seamless handover between wireless networks, improve signal quality, and enhance coverage area. The bridging mechanisms support various wireless protocols and standards, allowing devices to maintain connectivity while moving between different wireless environments or connecting to networks with different specifications.

- Protocol bridging systems: Protocol bridging systems facilitate communication between networks or devices using different communication protocols. These systems translate data formats and commands between incompatible protocols, enabling interoperability between diverse systems. The bridging mechanisms handle protocol conversion, data encapsulation, and address mapping to ensure reliable data transfer across heterogeneous network environments.

- Hardware bridging implementations: Hardware bridging implementations involve physical devices or components designed specifically for network bridging functions. These hardware solutions include specialized chips, circuit designs, and physical interfaces that facilitate network connections. The hardware components are optimized for efficient data transfer, minimal latency, and reliable operation in various environmental conditions, often incorporating redundancy features for mission-critical applications.

- Software-defined bridging solutions: Software-defined bridging solutions provide flexible and programmable approaches to network bridging. These systems use software controls to manage bridging functions, allowing for dynamic configuration and adaptation to changing network conditions. The software-based approach enables advanced features such as traffic prioritization, security filtering, and automated failover, while also supporting remote management and integration with broader network management systems.

02 Wireless communication bridging

Wireless communication bridging involves technologies that connect different wireless networks or extend wireless coverage. These solutions enable seamless handover between networks, improve signal quality, and enhance coverage area. The bridging mechanisms support various wireless protocols and standards, allowing devices to maintain connectivity while moving between different wireless environments.Expand Specific Solutions03 Data packet bridging and routing

Data packet bridging and routing technologies focus on efficiently transferring data packets between networks. These systems analyze packet headers, determine optimal paths, and manage traffic flow to ensure reliable data delivery. Advanced bridging solutions incorporate quality of service mechanisms, traffic prioritization, and congestion management to optimize network performance.Expand Specific Solutions04 Bridge architecture and implementation

Bridge architecture and implementation covers the structural design and deployment of bridging solutions. This includes hardware configurations, software components, and integration methodologies. Modern bridge implementations often feature modular designs, virtualization capabilities, and programmable interfaces that allow for flexible deployment across various network environments.Expand Specific Solutions05 Industrial and specialized bridging applications

Industrial and specialized bridging applications address unique requirements in specific sectors such as manufacturing, telecommunications, and critical infrastructure. These applications often incorporate enhanced security features, redundancy mechanisms, and specialized protocols. They are designed to operate in challenging environments and meet industry-specific standards for reliability and performance.Expand Specific Solutions

Key Industry Players in Mineral Composite Technologies

The rhodochrosite bridging in composite mixtures market is in an early growth stage, characterized by increasing research activities but limited commercial applications. The global market size remains relatively small, primarily driven by specialized industrial applications in materials science and chemical engineering. From a technical maturity perspective, the field is still developing, with academic institutions like Central South University and Guizhou University leading fundamental research, while companies such as LG Chem, PetroChina, and BASF are exploring practical applications. SINOPEC Beijing Research Institute and Changsha Research Institute of Mining & Metallurgy are advancing process technologies, while materials specialists like DuPont and Niterra are investigating composite integration opportunities. The technology shows promise but requires further development for widespread commercial adoption.

LG Chem Ltd.

Technical Solution: LG Chem has developed a proprietary composite bridging technology utilizing rhodochrosite (MnCO3) as a key component in their advanced materials. Their approach involves precise control of rhodochrosite particle size distribution (typically 0.5-10 μm) and surface modification techniques to enhance interfacial bonding between organic polymers and inorganic fillers. The company employs a specialized sol-gel process to create rhodochrosite-polymer networks that demonstrate superior mechanical properties. Their patented treatment method involves surface functionalization of rhodochrosite particles with silane coupling agents to improve dispersion and adhesion within composite matrices, resulting in composites with enhanced thermal stability and reduced hygroscopic expansion.

Strengths: Superior interfacial bonding between components; excellent dispersion control; enhanced mechanical properties. Weaknesses: Higher production costs compared to conventional fillers; requires specialized processing equipment; limited scalability for mass production applications.

Central South University

Technical Solution: Central South University has pioneered innovative assessment methodologies for rhodochrosite bridging in composite mixtures, particularly focusing on mineral processing applications. Their approach combines advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM) and X-ray photoelectron spectroscopy (XPS) to analyze the interfacial interactions between rhodochrosite and various matrix materials. The university's research team has developed a quantitative model that correlates rhodochrosite particle morphology, surface chemistry, and dispersion characteristics with composite performance metrics. Their methodology includes a novel in-situ observation technique that allows real-time monitoring of rhodochrosite bridging formation during composite curing processes, providing unprecedented insights into the kinetics of interface development.

Strengths: Comprehensive characterization capabilities; strong theoretical foundation; innovative in-situ monitoring techniques. Weaknesses: Laboratory-scale focus with limited industrial validation; requires expensive analytical equipment; methodology may be too complex for routine quality control applications.

Critical Patents in Rhodochrosite Composite Integration

Stable synthetic rhodochrosite and a method for the production thereof

PatentActiveUS11198618B2

Innovation

- Incorporating 0.03-0.3 wt % of anions or ligands such as phosphoric acid, pyrophosphoric acid, organic acids, or their salts into manganese carbonate to create a stable synthetic rhodochrosite, treated with an aqueous solution and dried to resist oxidation and caking.

Selective manganese extraction and recovery from aqueous solutions using NANO-titanate absorbents

PatentWO2025114752A1

Innovation

- The use of nano-titanate selective adsorbents to selectively adsorb manganese from aqueous solutions, allowing for its subsequent recovery and concentration, while also regenerating the adsorbent for repeated use.

Environmental Impact of Rhodochrosite in Composites

The incorporation of rhodochrosite into composite materials presents significant environmental considerations that warrant thorough examination. As a manganese carbonate mineral, rhodochrosite's extraction processes typically involve open-pit mining operations that can lead to habitat disruption, soil erosion, and potential water contamination. The mining activities associated with rhodochrosite acquisition have been documented to release particulate matter and potentially toxic elements into surrounding ecosystems.

When integrated into composite mixtures, rhodochrosite's environmental footprint extends throughout the product lifecycle. During manufacturing processes, energy consumption for grinding and processing the mineral contributes to carbon emissions. The bridging properties of rhodochrosite in composites, while technically advantageous, may require additional binding agents or treatments that introduce further chemical compounds into the production chain.

Leaching studies have indicated that under certain environmental conditions, manganese from rhodochrosite-containing composites can be released into soil and water systems. This is particularly concerning in acidic environments where the mineral's stability decreases significantly. Research has shown that manganese concentrations exceeding 0.05 mg/L in water bodies can adversely affect aquatic organisms and potentially enter the food chain.

The end-of-life management of rhodochrosite-enhanced composites presents additional environmental challenges. These materials often resist conventional degradation processes, leading to prolonged persistence in landfills. Recycling efforts are complicated by the heterogeneous nature of the composites and the difficulty in separating the rhodochrosite components from the matrix material.

Recent life cycle assessments have attempted to quantify the environmental impact of rhodochrosite in various composite applications. These studies suggest that while the mineral improves product durability—potentially extending useful life and reducing replacement frequency—this benefit must be weighed against extraction impacts and end-of-life considerations. The carbon footprint of rhodochrosite-containing composites varies significantly based on sourcing locations, with transportation emissions adding substantially to the overall environmental cost when the mineral is sourced from remote locations.

Emerging research focuses on developing more environmentally responsible approaches to rhodochrosite utilization in composites. These include using recycled rhodochrosite sources, implementing closed-loop manufacturing systems to capture and reuse process waste, and developing bio-based binding agents that reduce the need for synthetic chemicals in the composite formation process.

When integrated into composite mixtures, rhodochrosite's environmental footprint extends throughout the product lifecycle. During manufacturing processes, energy consumption for grinding and processing the mineral contributes to carbon emissions. The bridging properties of rhodochrosite in composites, while technically advantageous, may require additional binding agents or treatments that introduce further chemical compounds into the production chain.

Leaching studies have indicated that under certain environmental conditions, manganese from rhodochrosite-containing composites can be released into soil and water systems. This is particularly concerning in acidic environments where the mineral's stability decreases significantly. Research has shown that manganese concentrations exceeding 0.05 mg/L in water bodies can adversely affect aquatic organisms and potentially enter the food chain.

The end-of-life management of rhodochrosite-enhanced composites presents additional environmental challenges. These materials often resist conventional degradation processes, leading to prolonged persistence in landfills. Recycling efforts are complicated by the heterogeneous nature of the composites and the difficulty in separating the rhodochrosite components from the matrix material.

Recent life cycle assessments have attempted to quantify the environmental impact of rhodochrosite in various composite applications. These studies suggest that while the mineral improves product durability—potentially extending useful life and reducing replacement frequency—this benefit must be weighed against extraction impacts and end-of-life considerations. The carbon footprint of rhodochrosite-containing composites varies significantly based on sourcing locations, with transportation emissions adding substantially to the overall environmental cost when the mineral is sourced from remote locations.

Emerging research focuses on developing more environmentally responsible approaches to rhodochrosite utilization in composites. These include using recycled rhodochrosite sources, implementing closed-loop manufacturing systems to capture and reuse process waste, and developing bio-based binding agents that reduce the need for synthetic chemicals in the composite formation process.

Quality Control Standards for Mineral-Enhanced Mixtures

Quality control standards for mineral-enhanced mixtures, particularly those involving rhodochrosite, require comprehensive frameworks to ensure consistent performance and reliability. These standards must address the unique properties of rhodochrosite when used as a bridging agent in composite formulations, focusing on both physical and chemical parameters.

The primary quality control metrics for rhodochrosite-enhanced mixtures include particle size distribution, mineralogical purity, and bridging efficiency. Particle size distribution is critical as it directly impacts the bridging mechanism, with optimal ranges typically between 45-150 microns depending on the specific application. Variations outside these parameters can significantly compromise structural integrity and performance characteristics of the final composite.

Mineralogical purity standards typically require rhodochrosite content of at least 85%, with specific limits on contaminants such as quartz, calcite, and iron-bearing minerals that may interfere with bridging mechanisms. X-ray diffraction (XRD) and X-ray fluorescence (XRF) analyses are the preferred verification methods, with sampling protocols requiring representative testing at multiple production stages.

Bridging efficiency testing has evolved to include both static and dynamic evaluation protocols. The Bridging Efficiency Index (BEI), developed specifically for mineral-enhanced composites, measures the ability of rhodochrosite particles to form stable networks under varying pressure and temperature conditions. Industry standards now require a minimum BEI of 0.75 for high-performance applications, with testing conducted at application-specific conditions.

Moisture content represents another critical quality parameter, with standards typically limiting moisture to below 2% by weight to prevent agglomeration and ensure proper dispersion within the composite matrix. Thermal stability testing has also become standardized, with requirements for rhodochrosite to maintain structural integrity at temperatures ranging from -40°C to 200°C for most industrial applications.

Recent advancements in quality control standards have incorporated rheological property measurements, as the flow behavior of rhodochrosite-enhanced mixtures significantly impacts application performance. Viscosity profiles under varying shear rates (typically 0.1-100 s⁻¹) must fall within application-specific envelopes, with particular attention to thixotropic recovery rates after high shear exposure.

International standardization efforts have led to the development of ISO/TS 21236, which specifically addresses mineral bridging agents in composite formulations. This technical specification provides a unified framework for quality assessment, including sampling methodologies, test procedures, and acceptance criteria specifically tailored to rhodochrosite and similar minerals used in bridging applications.

The primary quality control metrics for rhodochrosite-enhanced mixtures include particle size distribution, mineralogical purity, and bridging efficiency. Particle size distribution is critical as it directly impacts the bridging mechanism, with optimal ranges typically between 45-150 microns depending on the specific application. Variations outside these parameters can significantly compromise structural integrity and performance characteristics of the final composite.

Mineralogical purity standards typically require rhodochrosite content of at least 85%, with specific limits on contaminants such as quartz, calcite, and iron-bearing minerals that may interfere with bridging mechanisms. X-ray diffraction (XRD) and X-ray fluorescence (XRF) analyses are the preferred verification methods, with sampling protocols requiring representative testing at multiple production stages.

Bridging efficiency testing has evolved to include both static and dynamic evaluation protocols. The Bridging Efficiency Index (BEI), developed specifically for mineral-enhanced composites, measures the ability of rhodochrosite particles to form stable networks under varying pressure and temperature conditions. Industry standards now require a minimum BEI of 0.75 for high-performance applications, with testing conducted at application-specific conditions.

Moisture content represents another critical quality parameter, with standards typically limiting moisture to below 2% by weight to prevent agglomeration and ensure proper dispersion within the composite matrix. Thermal stability testing has also become standardized, with requirements for rhodochrosite to maintain structural integrity at temperatures ranging from -40°C to 200°C for most industrial applications.

Recent advancements in quality control standards have incorporated rheological property measurements, as the flow behavior of rhodochrosite-enhanced mixtures significantly impacts application performance. Viscosity profiles under varying shear rates (typically 0.1-100 s⁻¹) must fall within application-specific envelopes, with particular attention to thixotropic recovery rates after high shear exposure.

International standardization efforts have led to the development of ISO/TS 21236, which specifically addresses mineral bridging agents in composite formulations. This technical specification provides a unified framework for quality assessment, including sampling methodologies, test procedures, and acceptance criteria specifically tailored to rhodochrosite and similar minerals used in bridging applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!