Iron cover

a technology of iron covers and irons, applied in the field of heating irons, can solve the problems of reducing the performance of skis, rubbing typically leaves a non-uniform and discontinuous layer of wax on the surface, and irons cannot be stowed in suitcases or kits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

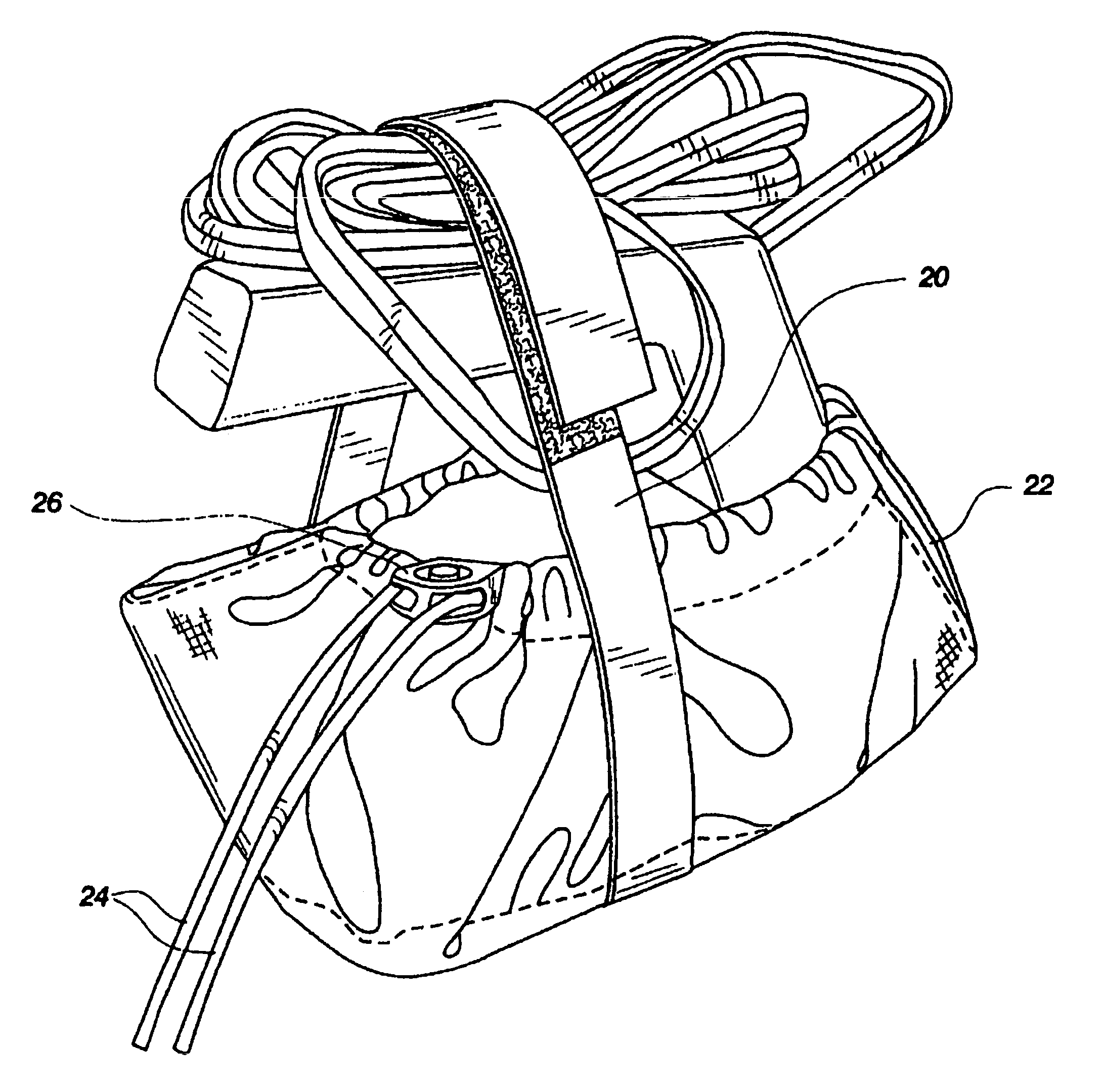

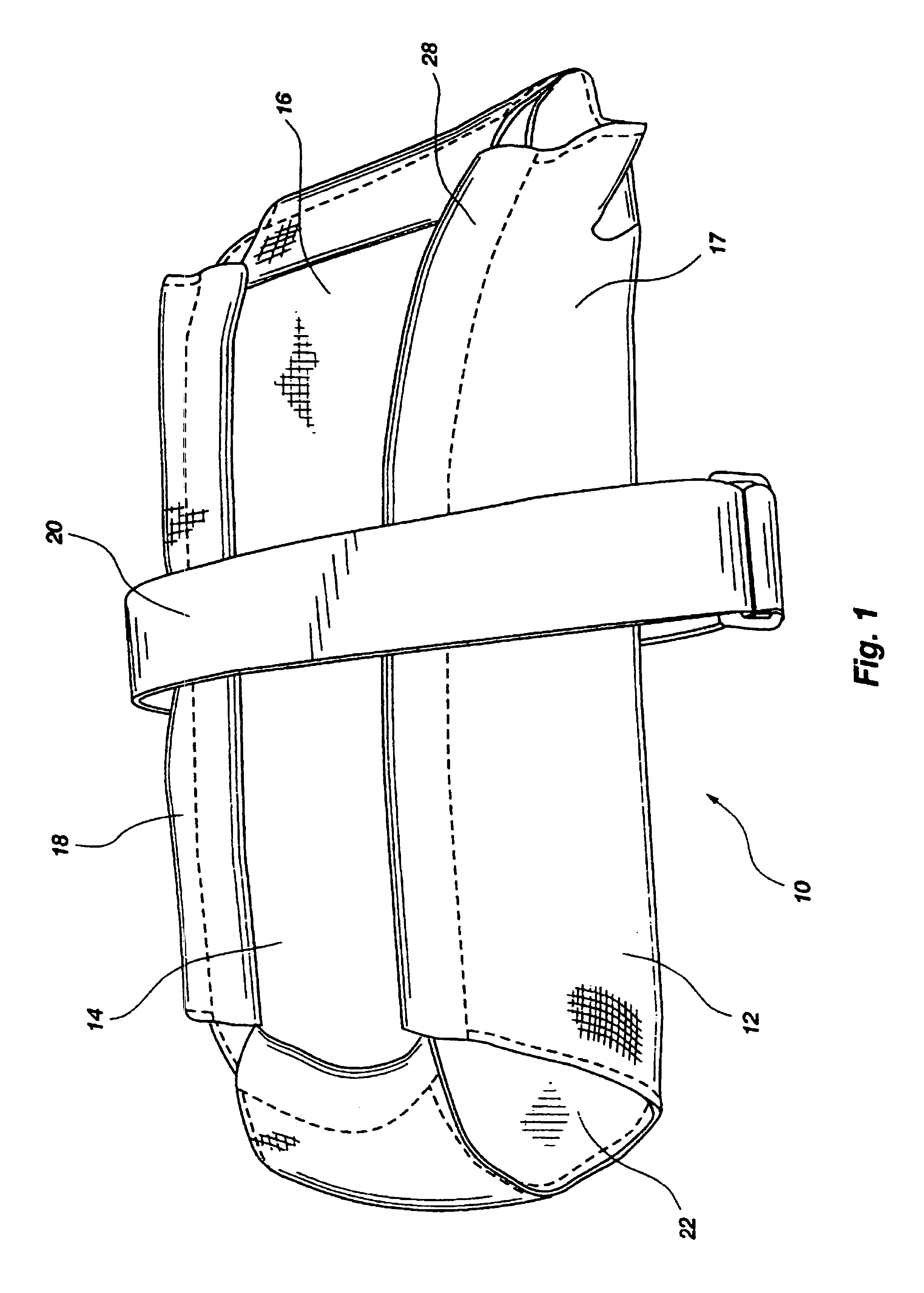

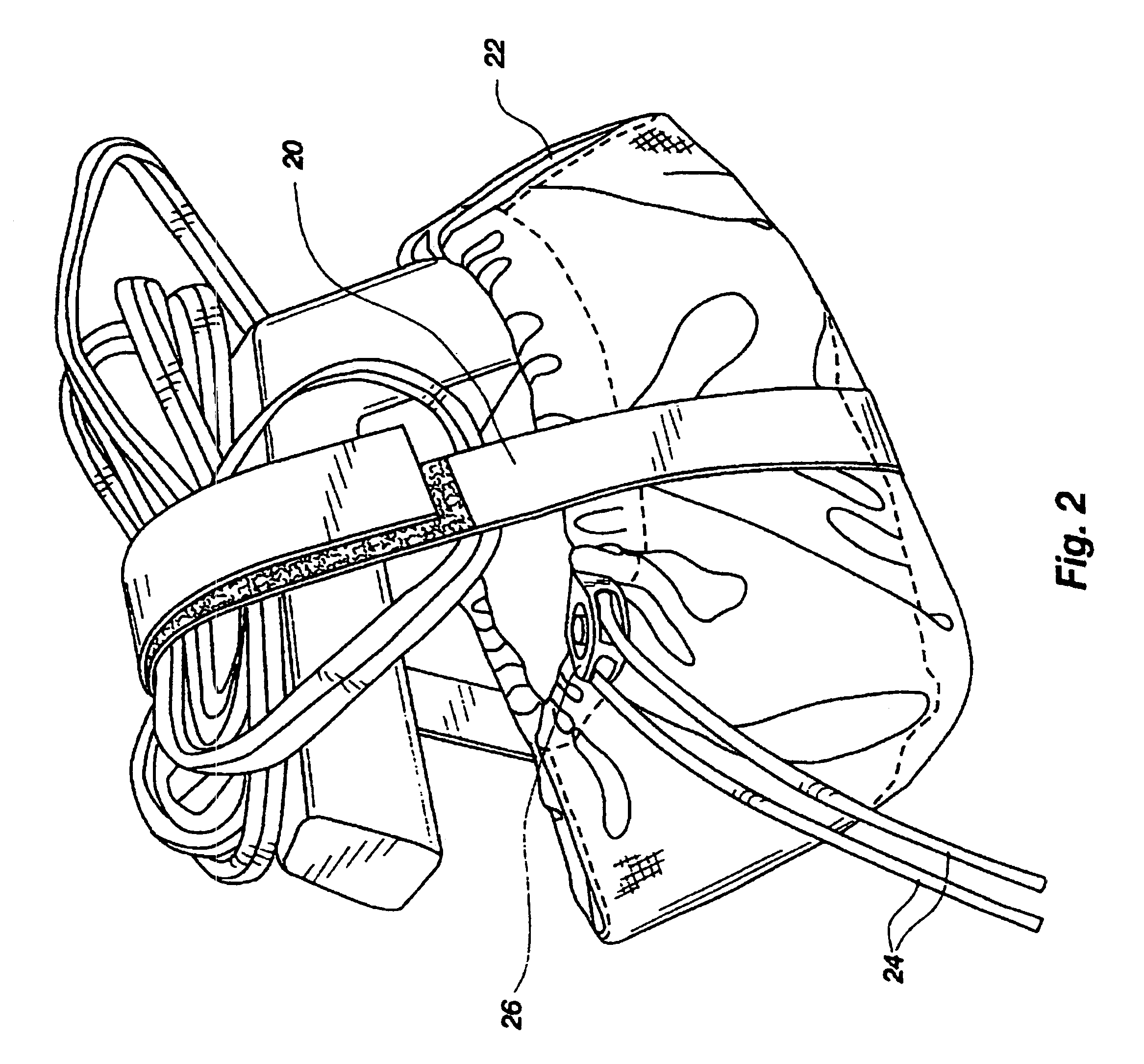

[0039]As shown in FIG. 1, the invention 10 comprises an iron cover 12 having a square padded bottom 14 formed by a flexible heat resistant reflective liner 16 sewn to a nylon cover 17 shaped to fit over and cover the sole of a ski wax iron. The padded bottom 14 is of sufficient thickness to prevent the sole of the iron from being damaged by accidental contact. Attached to the padded bottom 14 are a plurality of side flaps 18 also covered by the heat resistant liner 16. The side flaps 18 are expandably secured together to extend sufficiently around the sides of the iron placed therein to secure the iron cover there around with draw strings or other securing means. This preferred embodiment uses a reflective nylon heat resistant type of material for the heat resistant liner 16, and a durable nylon for the cover 17.

[0040]A strap webbing 20 storage system surrounds and is attached to the bottom 14 to secure the iron and power cord in place. Each side flap 18 is separated and structured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com