Method and apparatus for testing LCD panel array prior to shorting bar removal

a technology of liquid crystal display and panel array, which is applied in the direction of optical apparatus testing, television system, instruments, etc., can solve the problems of pixel short circuit and inactive pixels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Panel Configuration

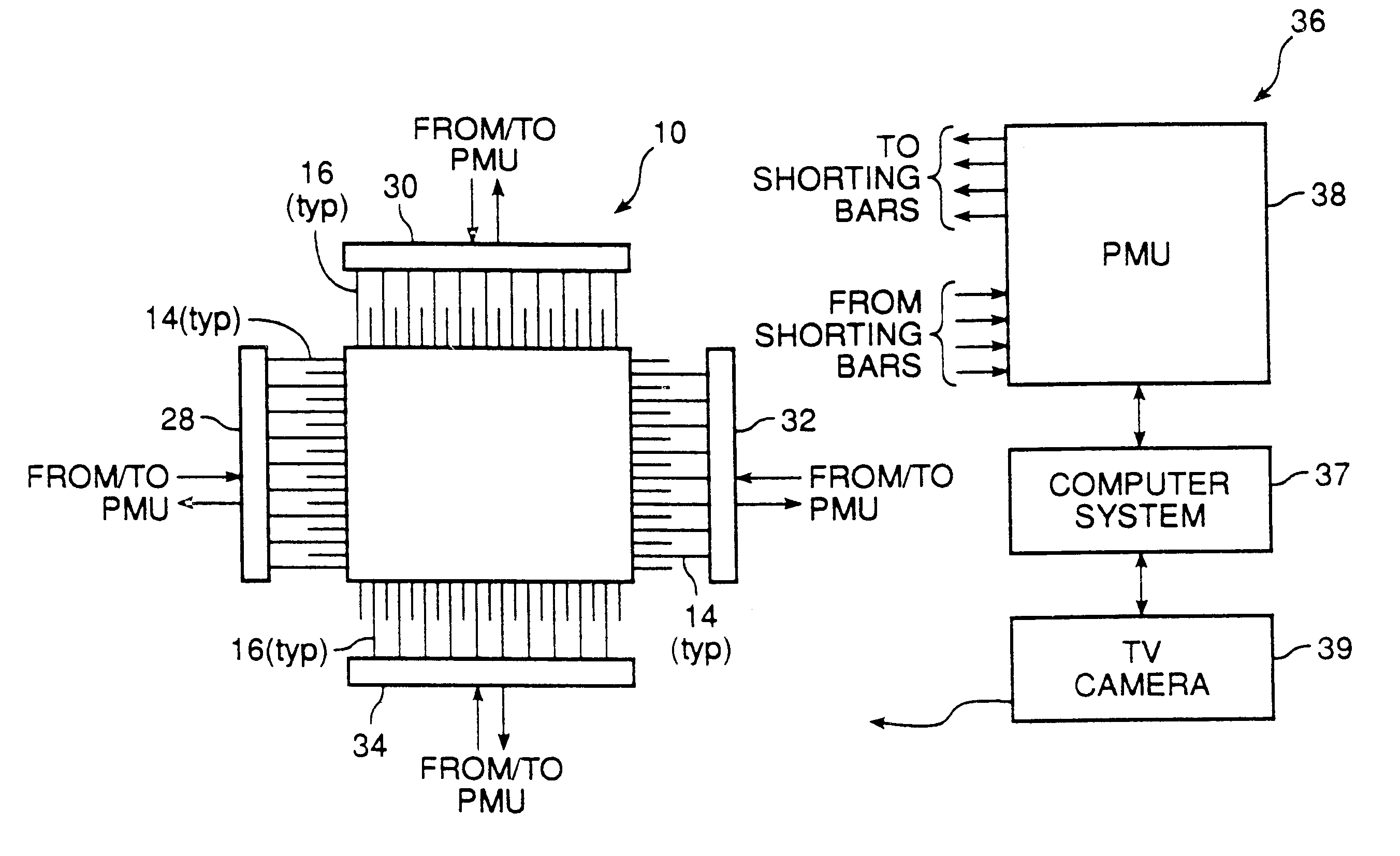

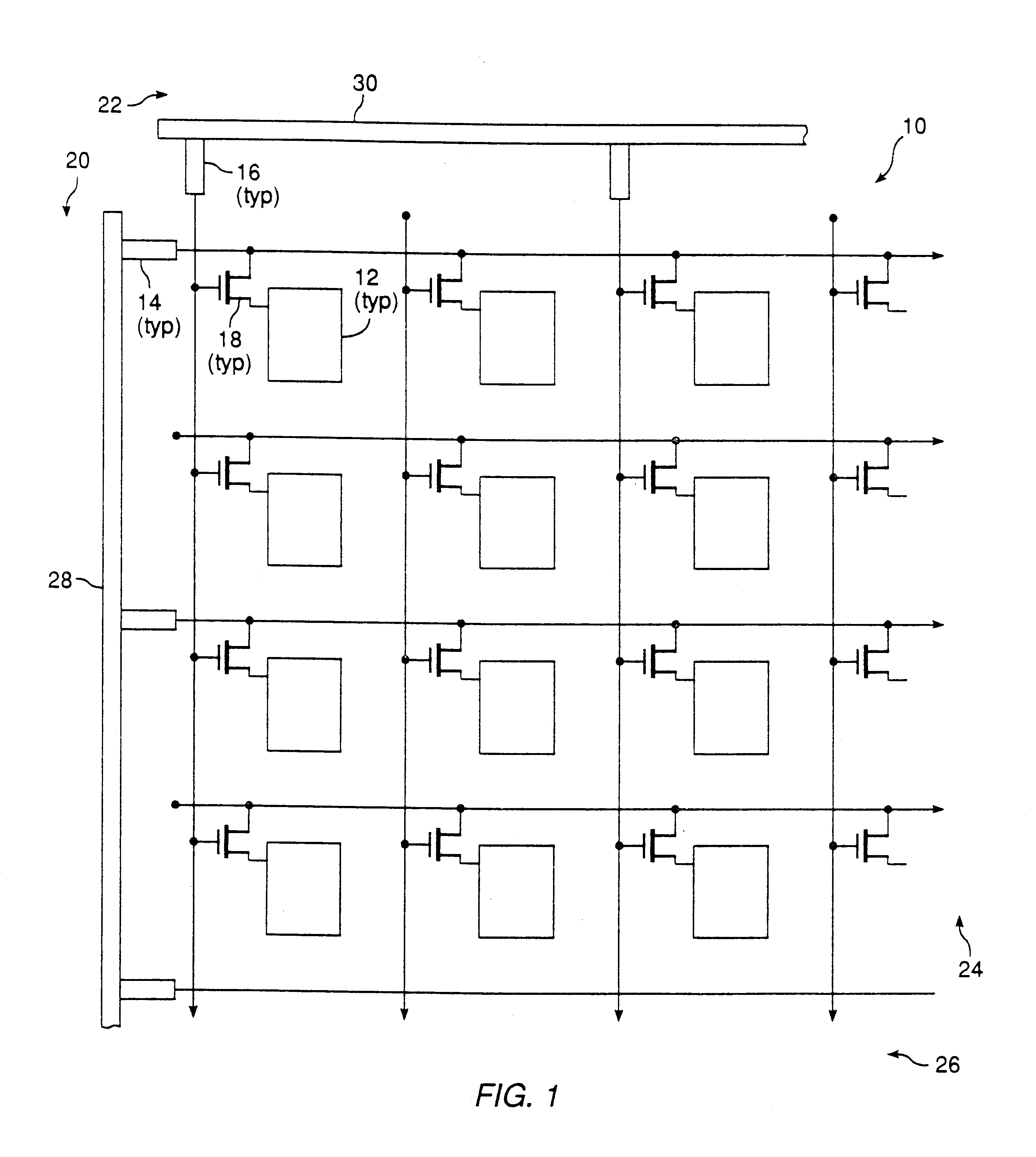

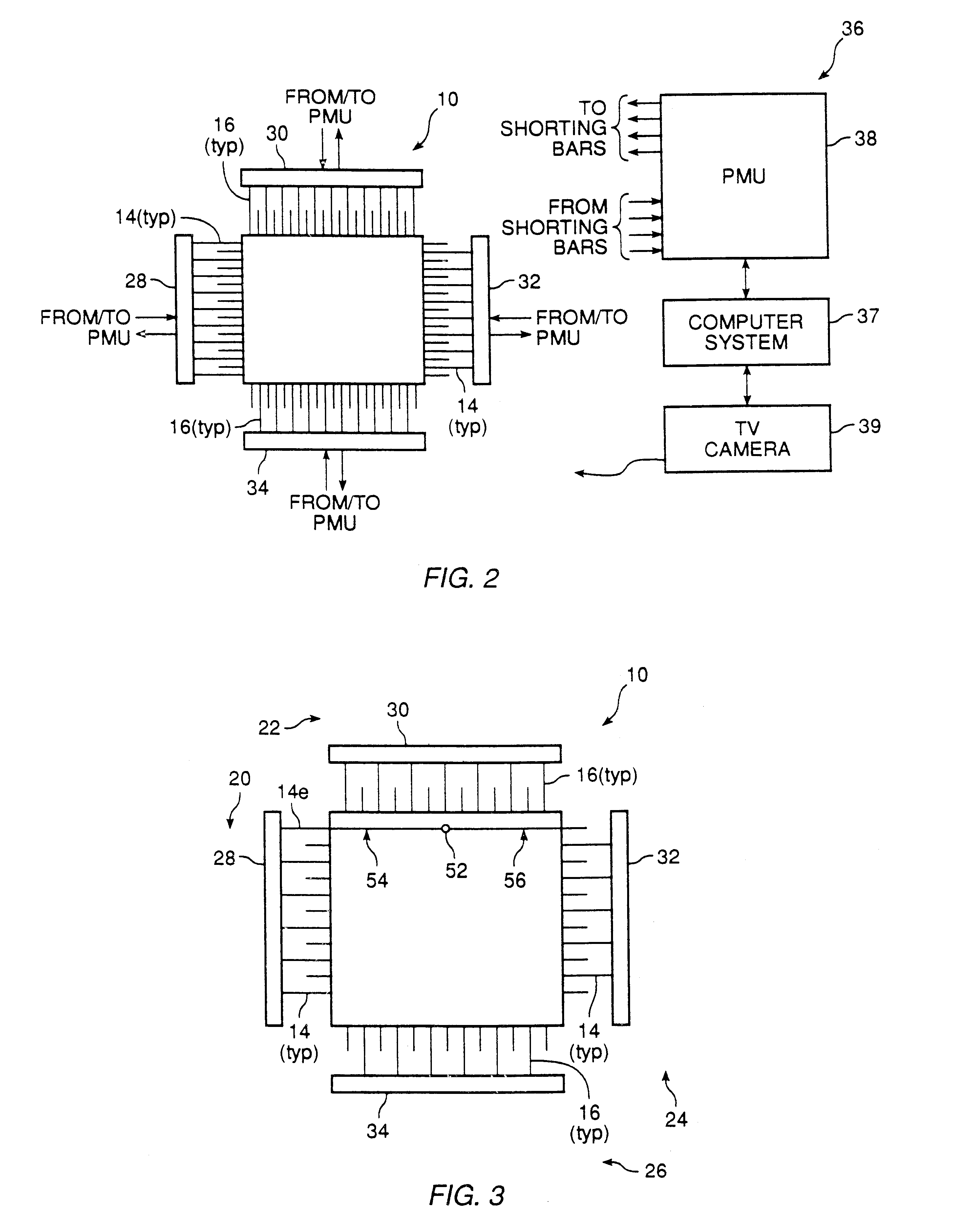

Referring to FIG. 1, a section of an LCD panel 10 is shown including several pixels 12. Associated with each pixel 12 is a drive line 14, a gate line 16, and a drive element 18, as previously described. For an interdigitated panel (shown), every other drive line is terminated along one panel boundary 20, while the other drive lines are terminated along the opposite, but parallel, boundary 24 (see FIG. 2). Similarly, every other gate line 16 is terminated along one panel boundary 22 adjacent and generally orthogonal to the drive line panel boundaries 20, 24, while the other gate lines 16 are terminated along the opposite panel boundary 26.

During final testing of the LCD panel 10, the electro-static discharge shorting bars are present. As shown in FIGS. 1-3, there are four shorting bars 28, 30, 32, 34 for an interdigitated panel, one at each edge of the panel 10. Bar 28 shorts the drive lines 14 terminating at edge 20. Bar 30 shorts the gate lines 16 terminating at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| optical sensing | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com