Loading apparatus for dust collection containers

a technology for loading apparatus and dust collection containers, applied in the direction of vortex flow apparatus, cleaning equipment, separation process, etc., can solve the problems of aggravated cumbersome operation, low mechanical advantage, and high cost of specialized lids and containers, and achieves simple manufacturing, ease and rapidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Embodiments of the present invention will now be described by way of example only, with reference to the accompanying drawings.

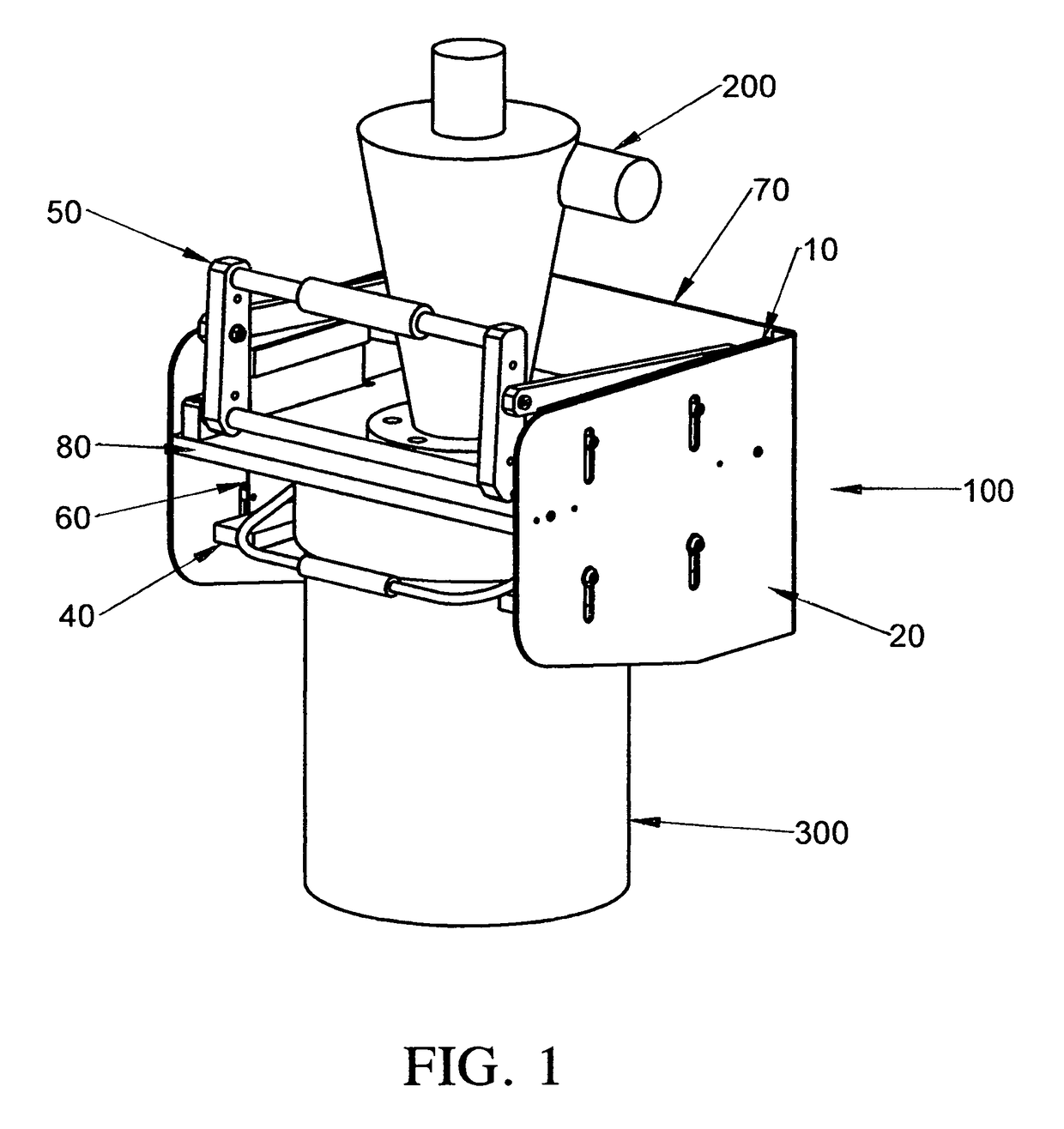

[0033]The present invention relates to a loading apparatus 100 for dust collection containers intended for a cyclonic dust separator system.

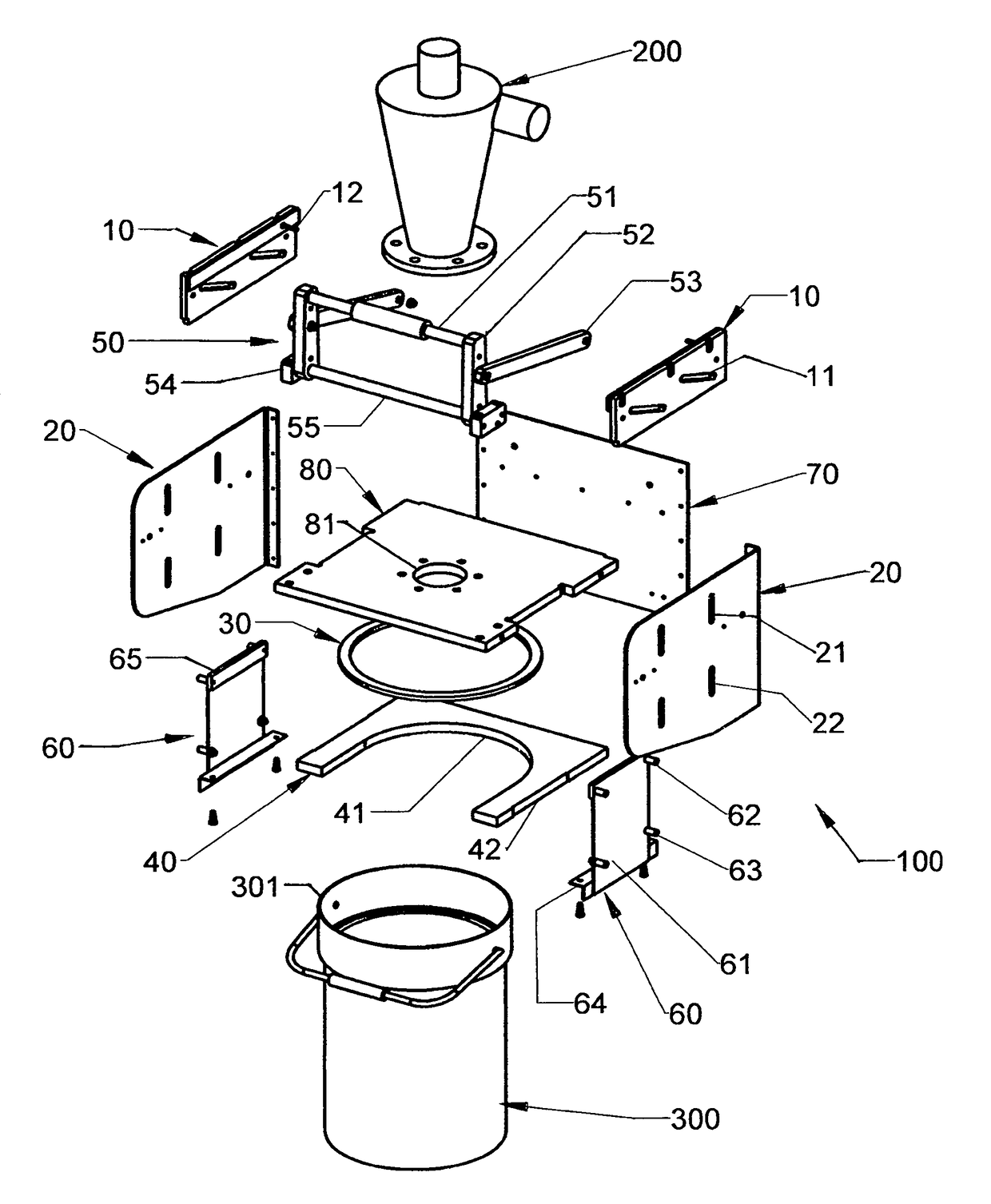

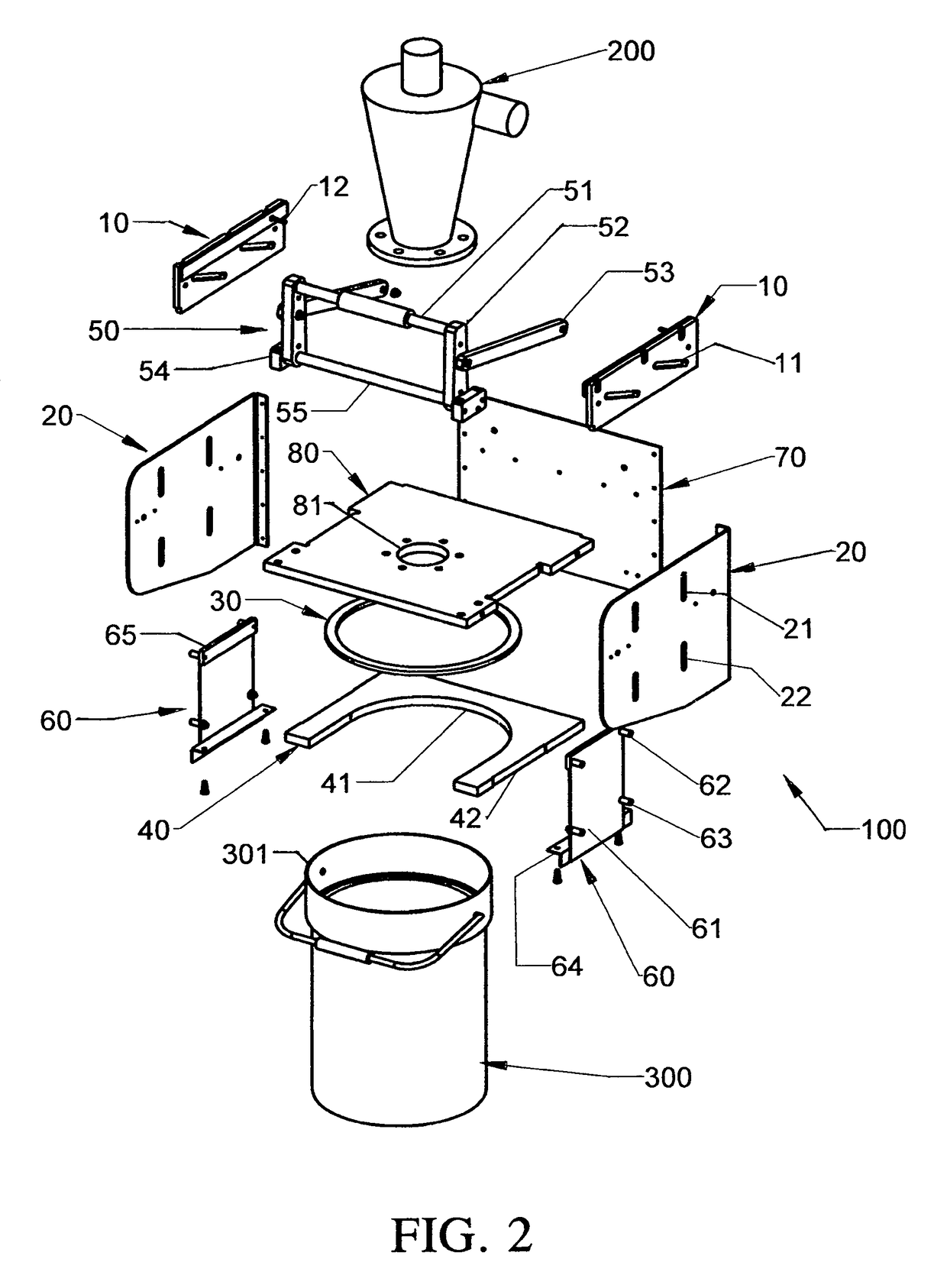

[0034]Referring to FIG. 1 and FIG. 2, there is shown a loading apparatus according to a first embodiment of the present invention. The loading apparatus 100 is composed of a stationary platform 80, rear plate 70, two side plates 20, two suspension brackets 60, two sliders 10, a lever mechanism 50, an annular gasket 30, and a U-shaped member 40.

[0035]The structure consists of a planar stationary platform 80, a laterally disposed rear plate 70 and two laterally disposed side plates 20, the rear plate 70 and side plates 20 permanently attached with a plurality of fasteners to the stationary platform 80. Collectively, this forms a rigid, unitized structure that is vital to the operation of this embodiment. The unified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| weights | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com