Controlling method of robot system, program, recording medium, and robot system

a robot system and control method technology, applied in the field of robot systems, can solve the problems of reducing movement accuracy, requiring a skilled technician to take a long time, and unable to highly accurately detect the origin offset of the respective joints, so as to achieve the effect of accurately determining the presence or absence of an origin offs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

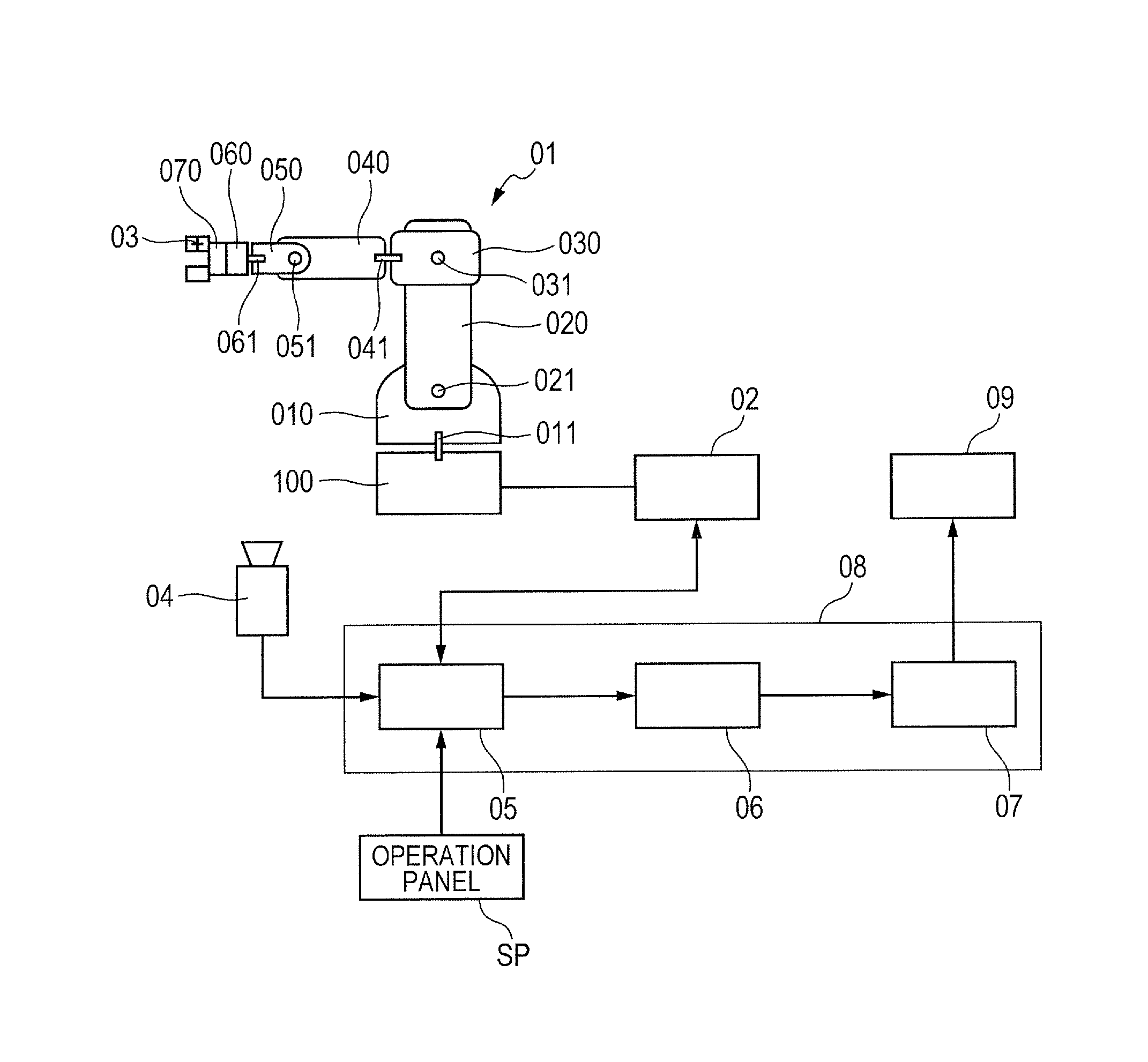

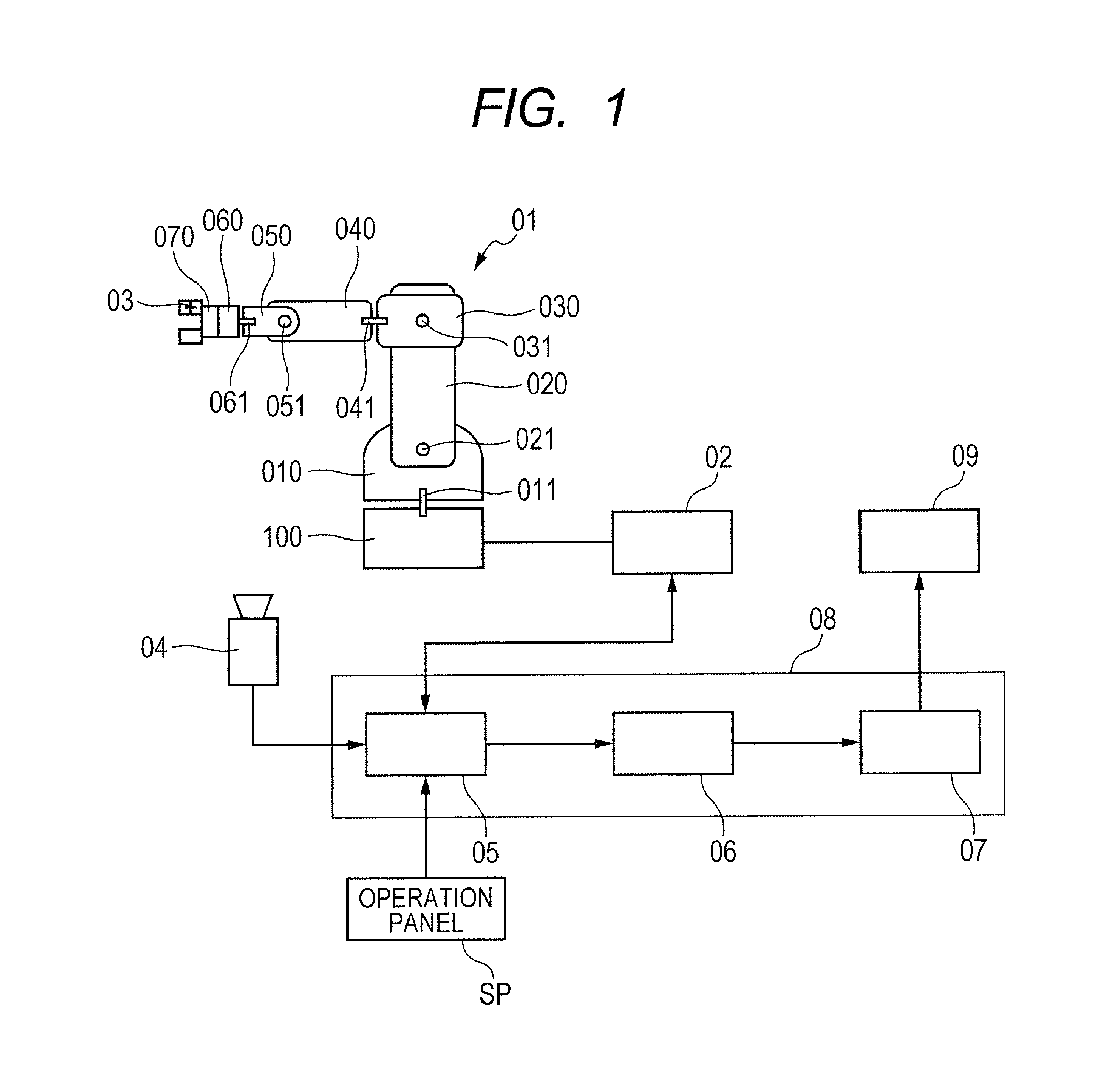

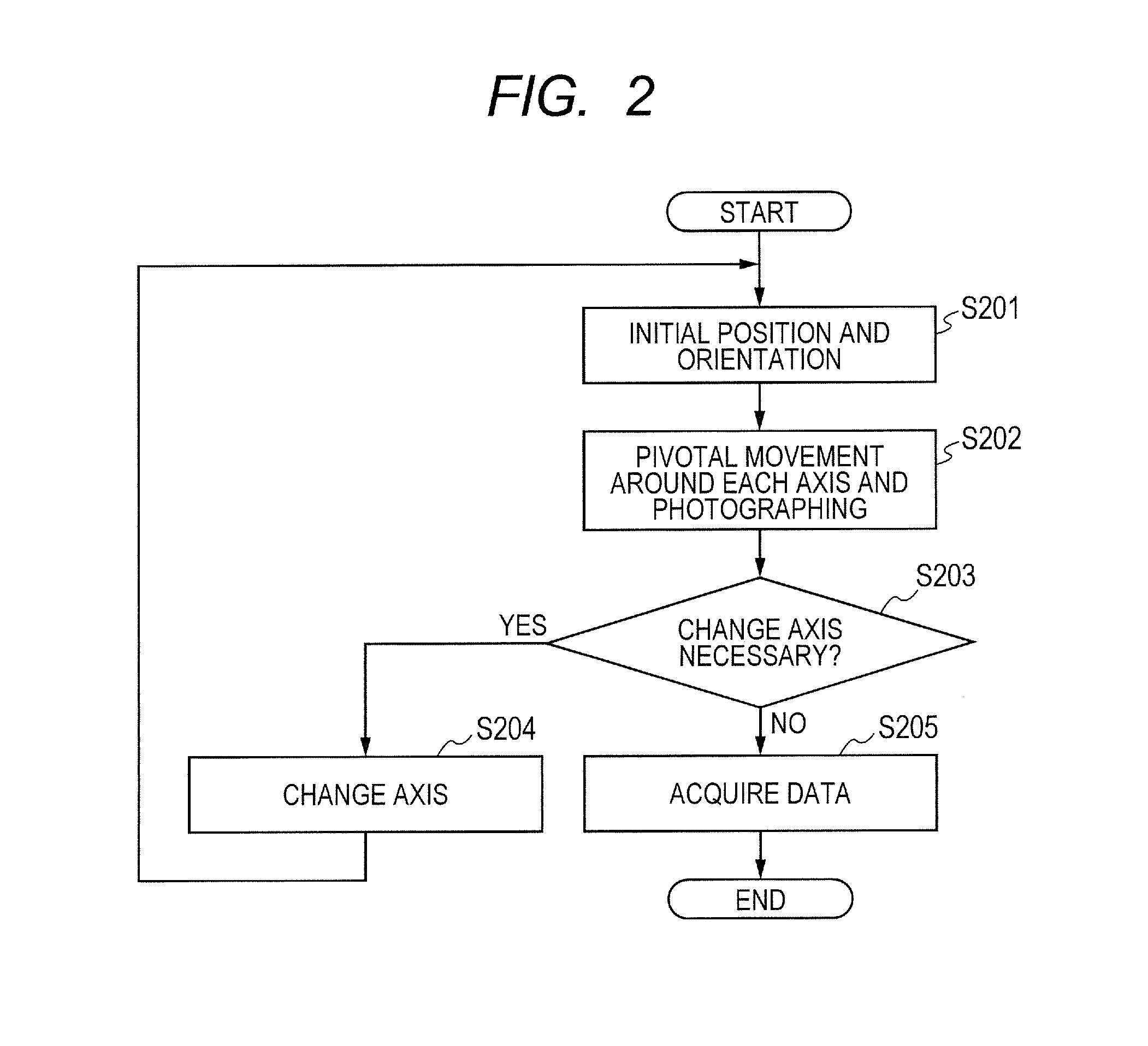

[0022]FIG. 1 is a diagram illustrating an overall configuration of a robot inspecting system of Embodiment 1. As illustrated in FIG. 1, a robot system includes: a robot 01, which is an example of a multi joint robot; and a camera 04, which is an example of a camera. A computer of a controlling unit 08, which is an example of a controlling unit, executes a program to control this system. The program is recorded in a recording medium, such as an optical disk, and then provided.

[0023]The robot 01 is a six-axis multi joint robot that includes an end effector 070 on a link 060 at a front end. A base 100 and a link 010 of the robot 01 are coupled to each other by a torsional joint 011 that rotates around a rotational axis in the Z-axis direction. The torsional joint 011 has a movable range of ±180 degrees from an initial position and orientation.

[0024]The link 010 and a link 020 of the robot 01 are coupled to each other by a pivotal joint 021 that rotates around a rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com