Cart accessory handle for lifting and dumping

a technology for accessories and carts, applied in the direction of hand cart accessories, children carriages/perambulators, vehicles, etc., can solve the problems of spitting in the vicinity, difficult for a second groom to help lift and dump contents, etc., to save time and improve user safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

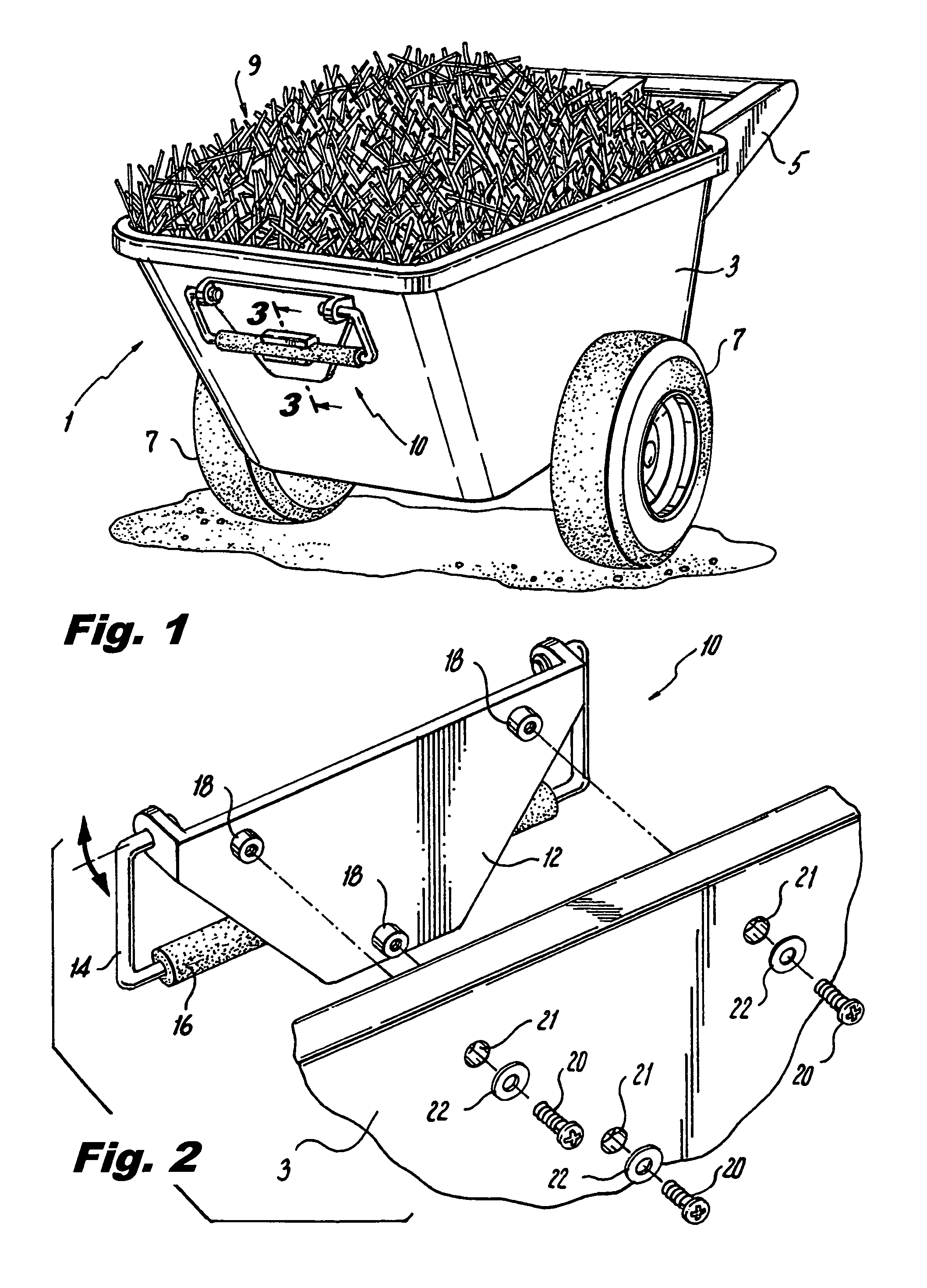

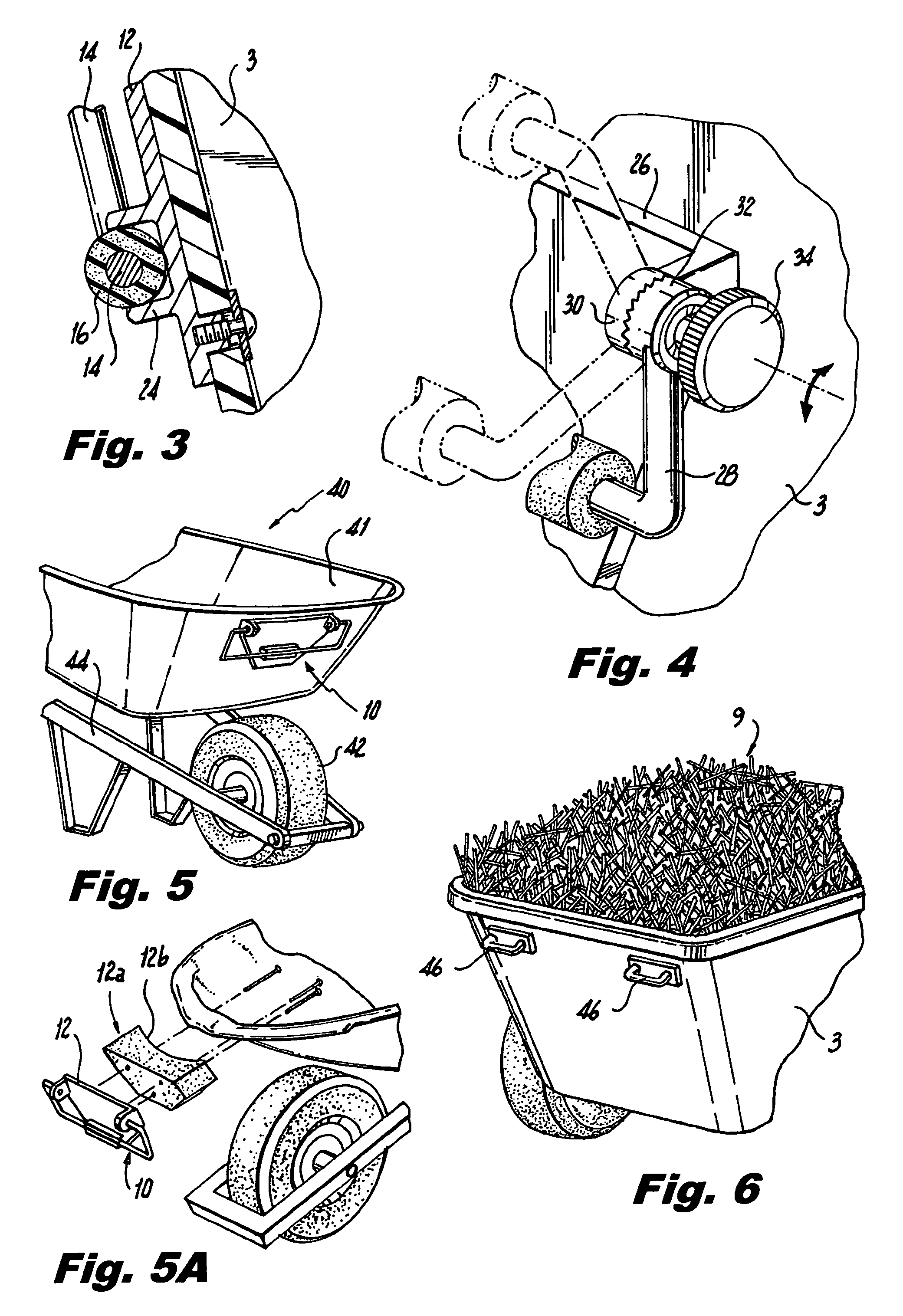

[0023]FIG. 4 shows the details of a second embodiment accessory front handle assembly. Frame 26 is rigidly attached to fixed ratchet member 30 while handle 28 is rigidly attached (as by welding, for example) to rotatable ratchet 32. Screw knob 34 forces the ratchet faces together to lock the position of handle 28 in any desired position as indicated by the two phantom views. This is ergonomically superior to handle 10 assembly as it affords rigidity to a handle 28 during the lifting and dumping procedure. The ratchet assembly 32 includes a fixed ratchet member 30 mounted on one of said forwardly extending members 28 of the bracket, a mating, rotatable ratchet member 32 attached to the corresponding end arm of the adjustable handle, and a screw knob 34 to separate the fixed and rotatable ratchet members 30, 32 temporarily to allow the resilient grip 16 to be positioned at any one of multiple positions between the parked position and the fully deployed position, whereby the elongated ...

third embodiment

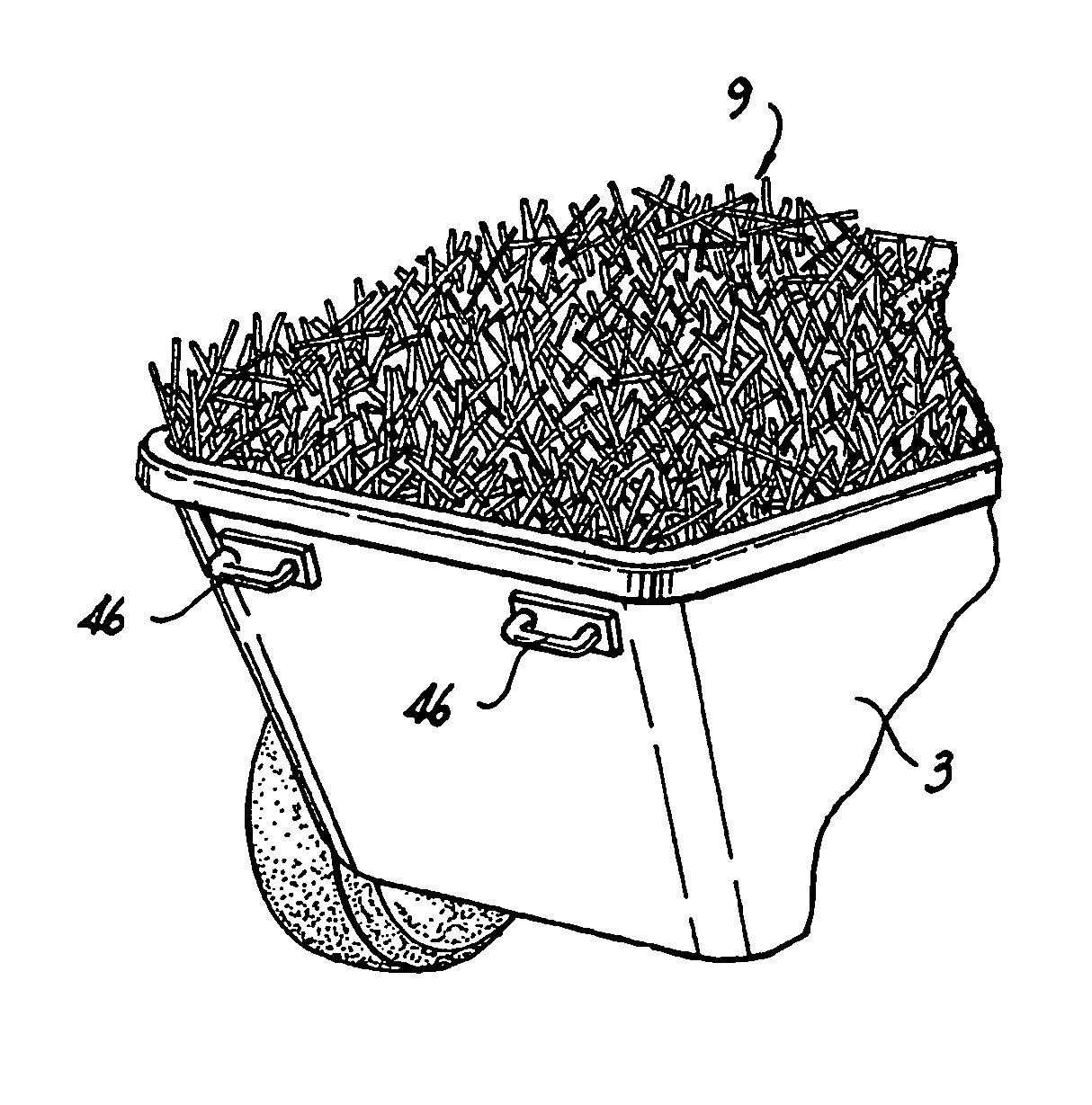

[0024]FIG. 6 shows accessory handle in which two separate short handles 46 substitute for a single centrally located handle. The separation of handles 46 afford good torque transfer to bin 3 for dumping.

[0025]FIG. 7 illustrates the equal height of the rear pushing handle and the grip 16 of handle assembly 10 when handle is at deployed height. It is this equal height at the level close to the top of bin 3 that is most useful for lifting and dumping. FIG. 7 also illustrates the equal height of the rear pushing handle 5 and the grip 16 of handle assembly 10 when the handle is at its deployed height. It is this equal height at the level close to the top of bin 3 that is most useful for lifting and dumping. This height also enables the users, such as two grooms at a racetrack, to have the respective handles 5 and 10 at equal chest height when the biceps are strongest at an ergonomic right angle, when tipping the contents 9 of the cart 1 into a dumpster 53. If the handles 5 and 10 were mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com