Disc filtration device

a filtration device and disc technology, applied in the direction of gravity filters, loose filtering material filters, cartridge filters, etc., can solve the problems of mechanical deformation, high risk, and risk of dismounting, and achieve the effect of eliminating the risk of falling, stable mechanical behaviour, and easy maintenance of the filtration facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

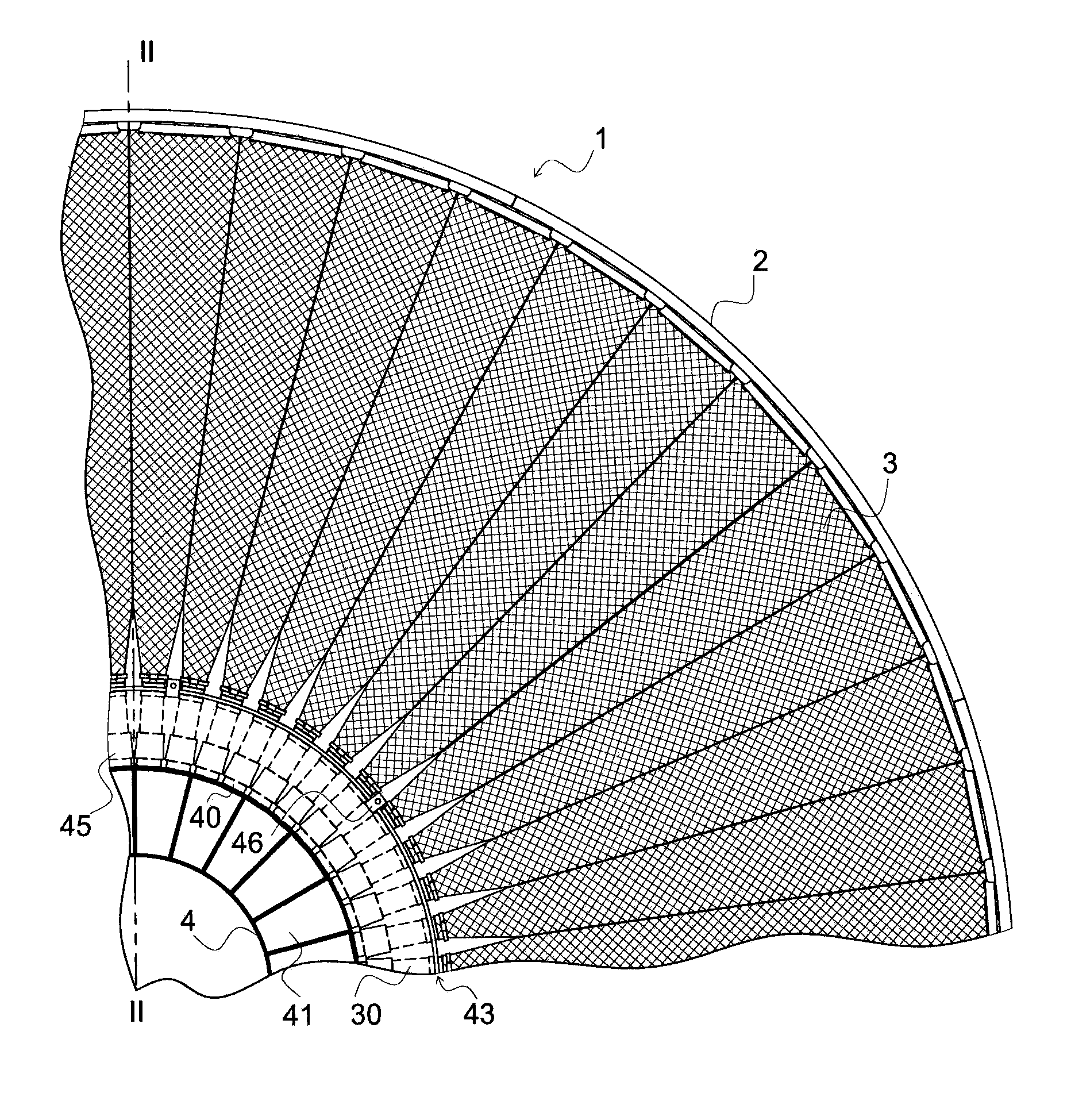

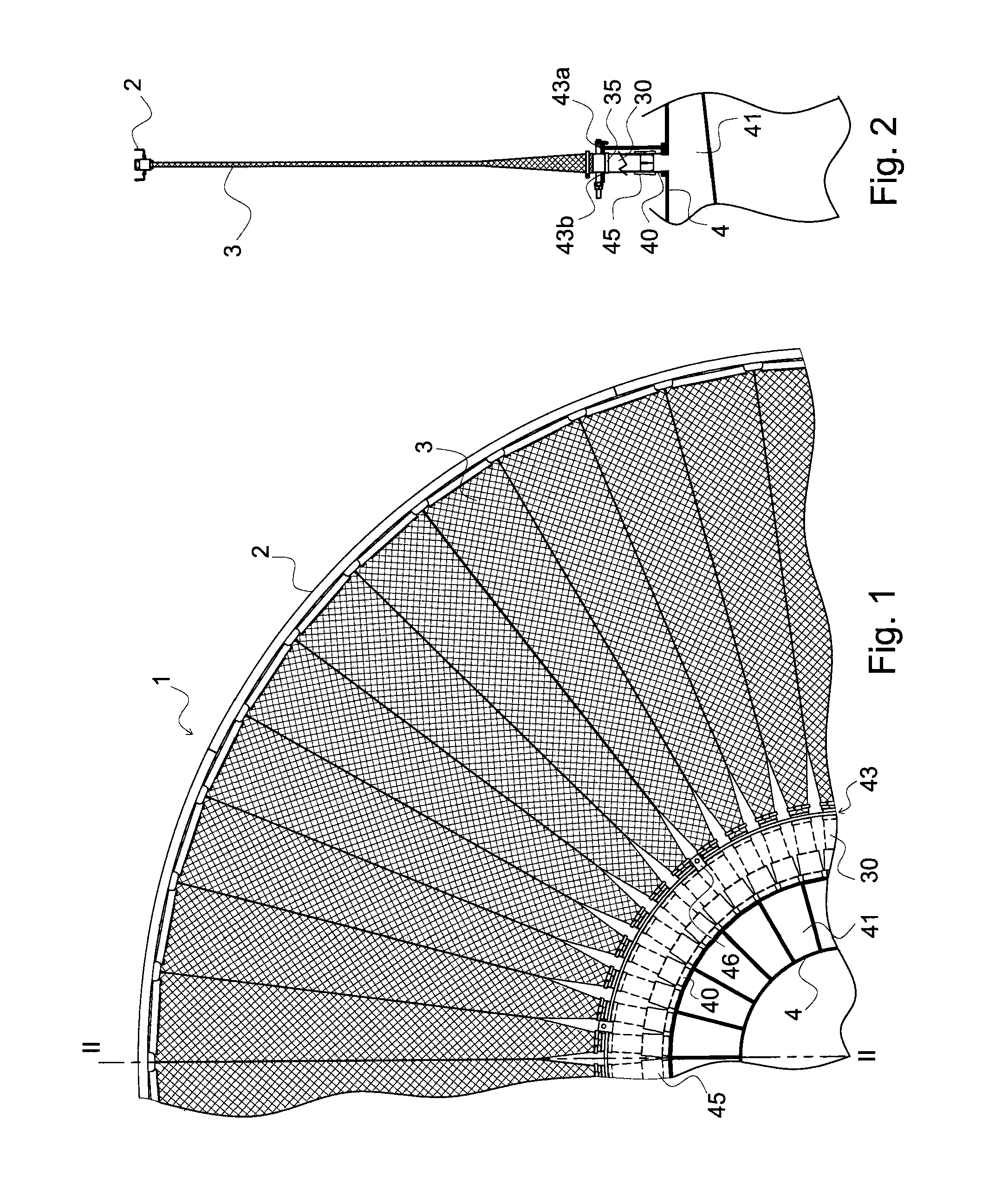

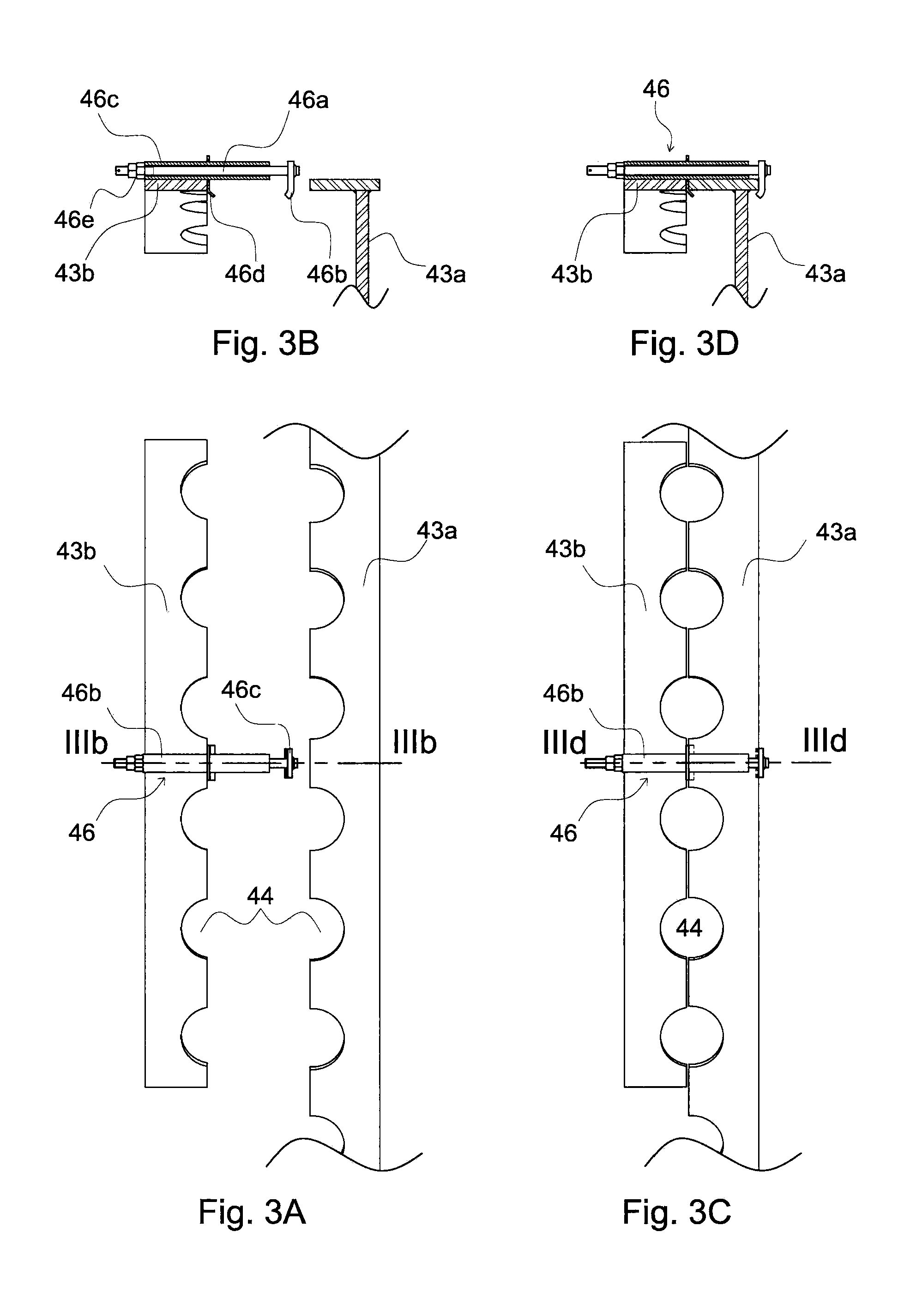

[0031]The filter device shown in FIGS. 1 and 2 includes a disc 1 provided with a rim 2 holding a plurality of filtering sectors 3. The sectors 3 are each composed of a triangular frame 31 made of a U-shaped section inserting a structure 32 in charge of draining the filtrates towards the outlet 30 provided with a tip 33, as shown more particularly in FIGS. 4A to 4C, 7A and 7B.

[0032]The sectors 3 are introduced into and accommodated in a triangular pocket 34 made from a filtering cloth opened at the base of the triangle. This pocket is further closed by folding the cloth on either side of the external edge of the sector and by wedging the cloth using a cloth clip 8 in the corner using the structure 32 supporting the cloth and the U-shaped frame 31 of the sector 3 which covers same as shown in FIG. 7B. The cloth clip 8 is made with a U-shaped section the sides of which form a jaw 82, such jaw extends almost up to the frame 31 of the sector so that it will be folded on the structure onl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stress | aaaaa | aaaaa |

| elastic | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com