Differential head integrated touchdown sensors for hard disk drives

a technology of hard disk drives and integrated sensors, which is applied in the field of differential head integrated touchdown sensors for hard disk drives, can solve the problems of drive failure, no single technique working across all media radii,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

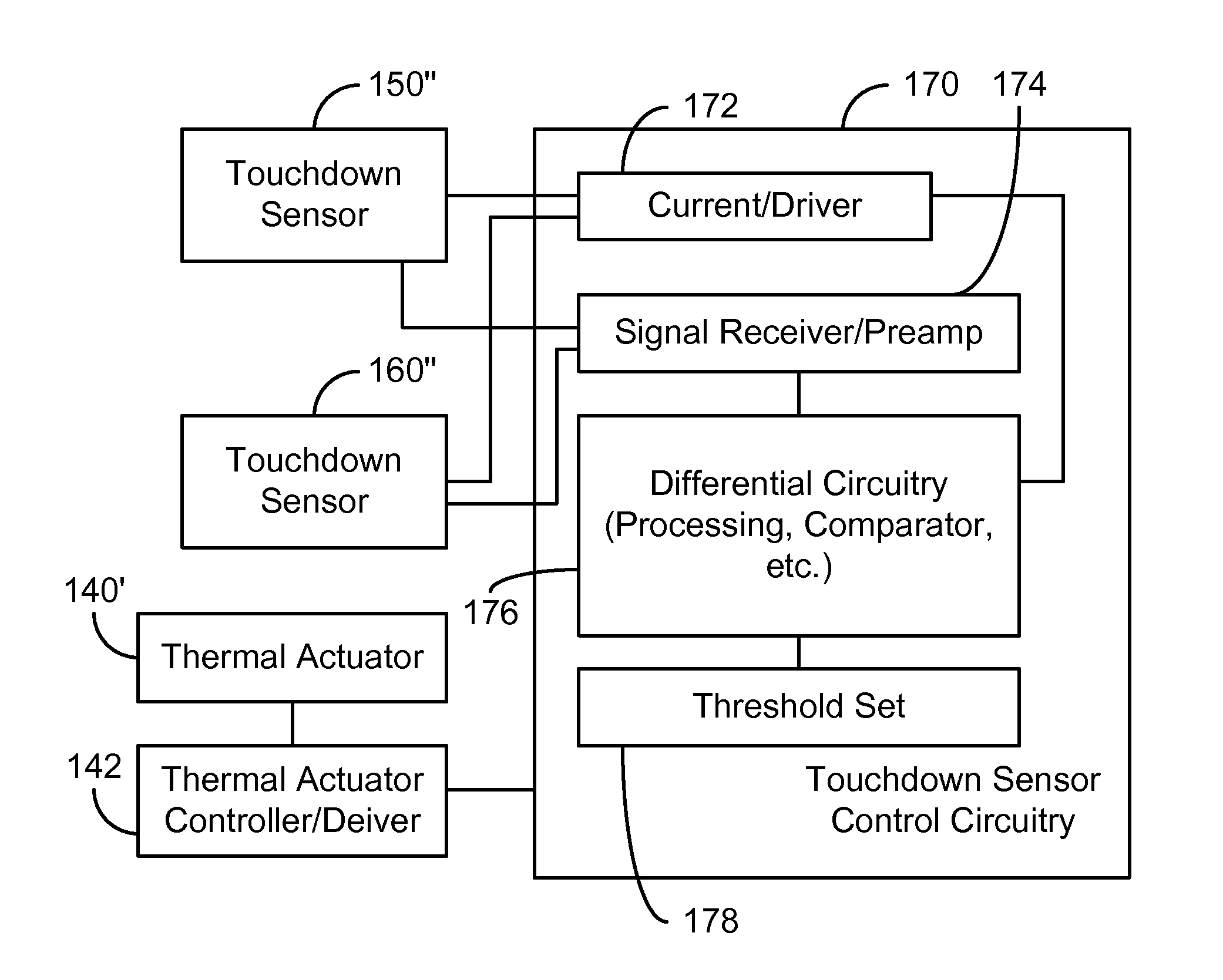

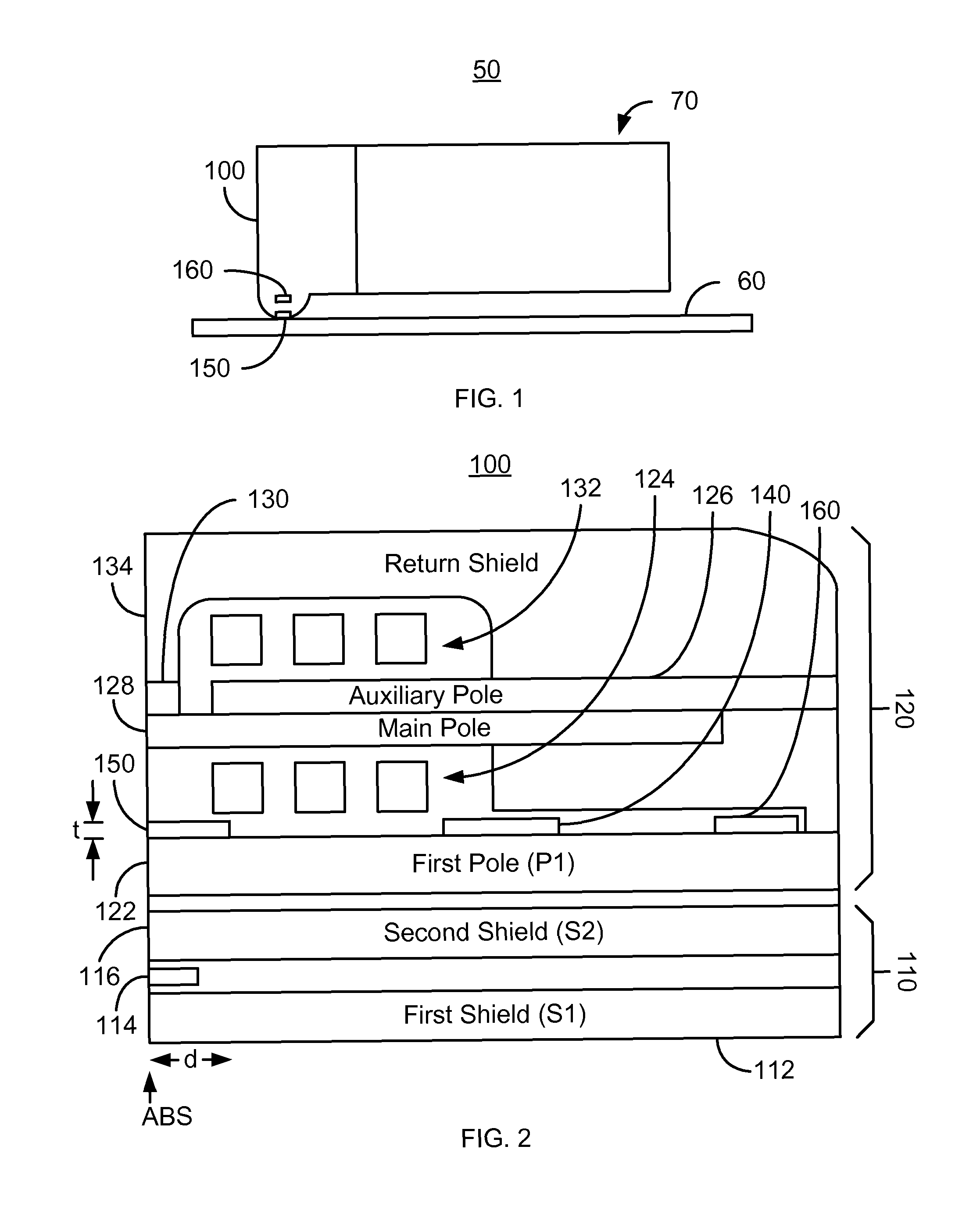

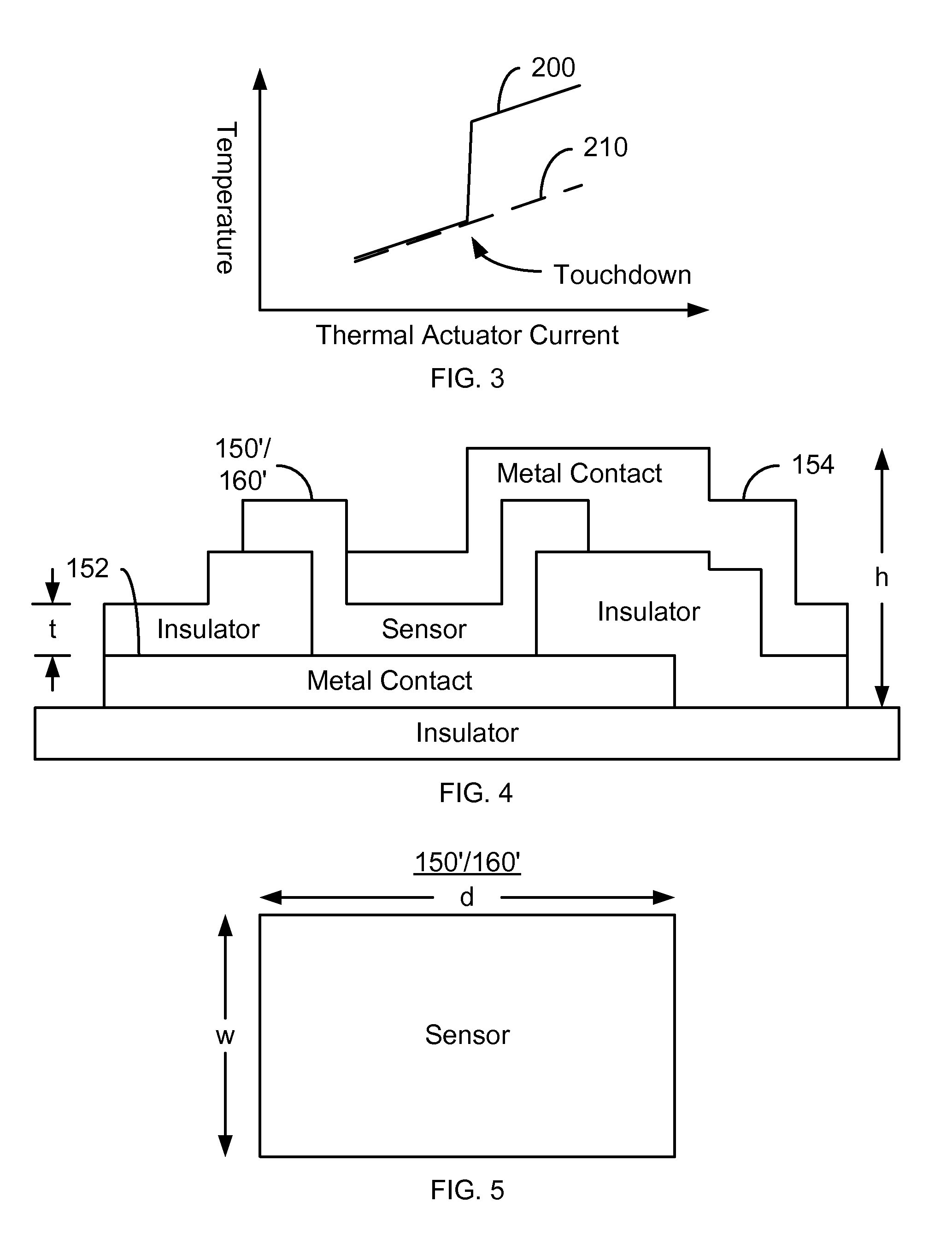

[0013]FIG. 1 is a diagram of a portion of an exemplary embodiment of a disk drive 50. For simplicity, components are omitted. In addition, for clarity, FIG. 1 is not drawn to scale. The disk drive 50 includes a media 60 and a slider 70. On the slider 70 resides head 100, which includes integrated touchdown sensors 150 and 160. Each of the touchdown sensors 150 and 160 is a thermal sensor and, in one embodiment, is a thermistor.

[0014]The touchdown sensor 150 in combination with the touchdown sensor 160 detects touchdown based upon the temperature of the head 100. The disk drive 50 is shown at touchdown. Consequently, the head 100 contacts the media 60 in a region of the ABS termed a touchdown region. Frictional heating due to contact between the media 60 and head 100 raises the local temperature of the head 100 in the region proximate to where touchdown occurs. The touchdown sensor 150 is located in this touchdown region. Thus, the touchdown sensor 150 is able to detect a local tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com