Linear motor automatic control circuit assembly for controlling the operation of a 3-phase linear motor-driven submersible oil pump of an artificial oil lift system

a technology of automatic control circuit and linear motor, which is applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problems of inability to work with continuous pump speed adjustment, limited discrete stroke number adjustment, complicated pump speed adjustment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

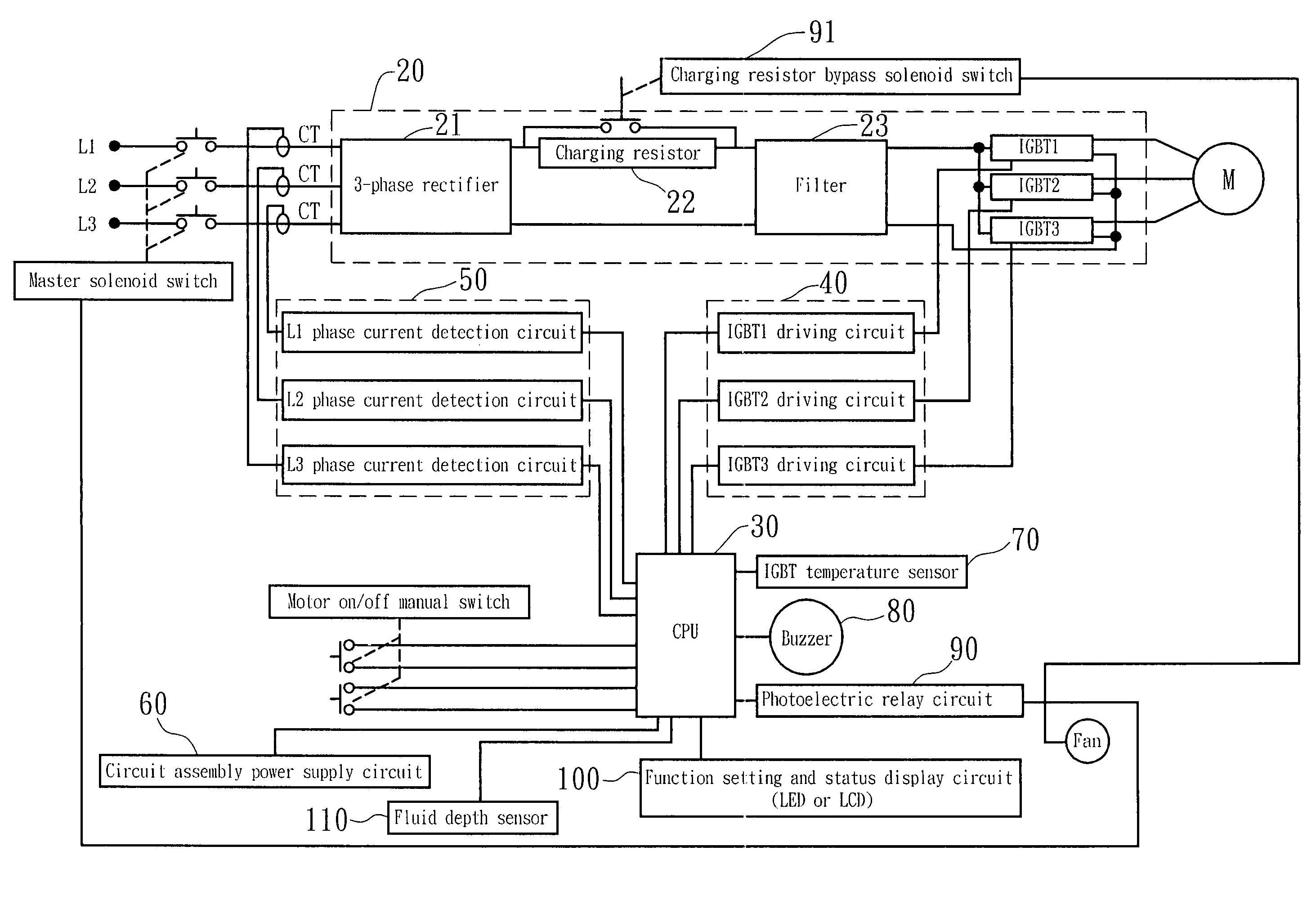

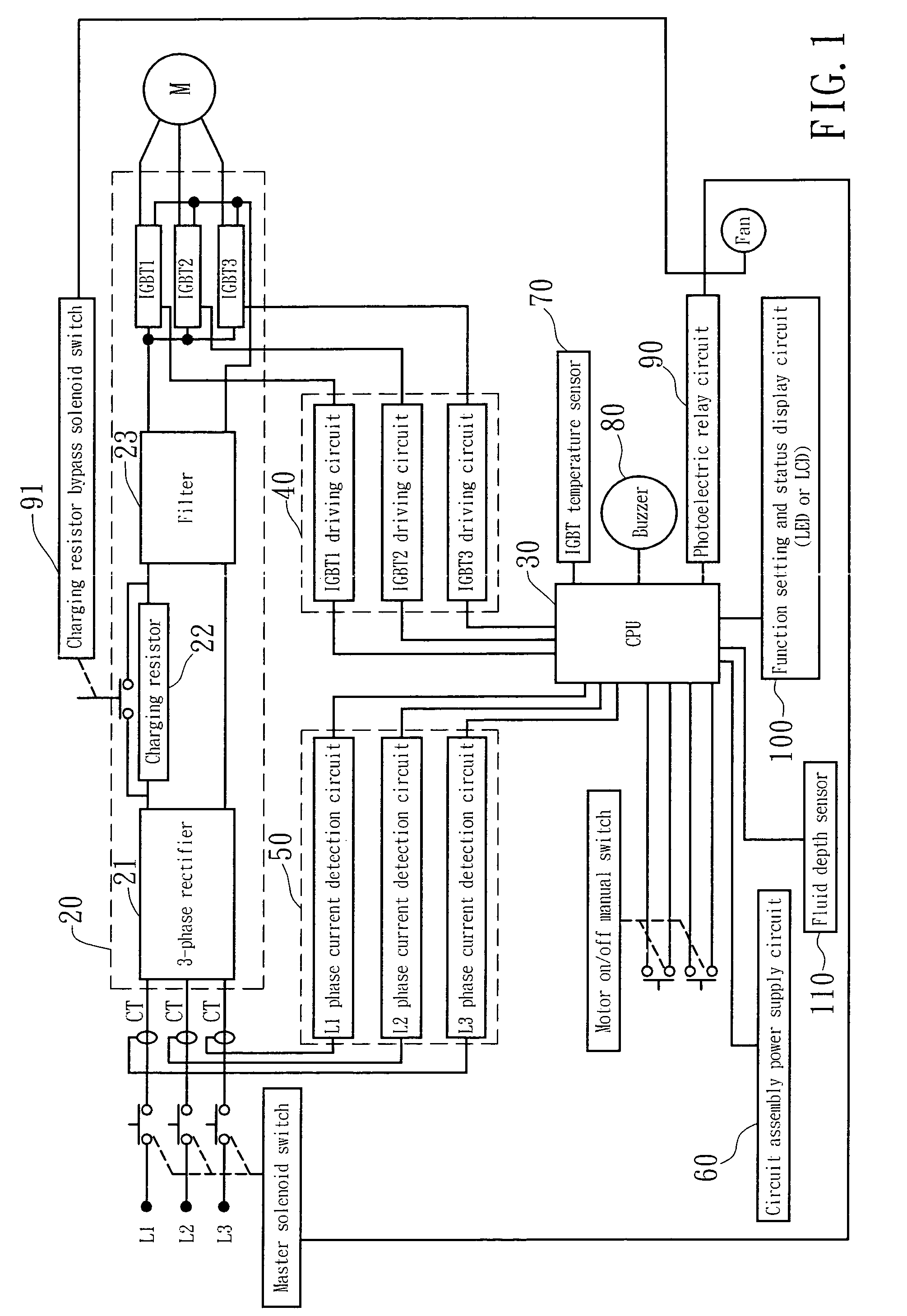

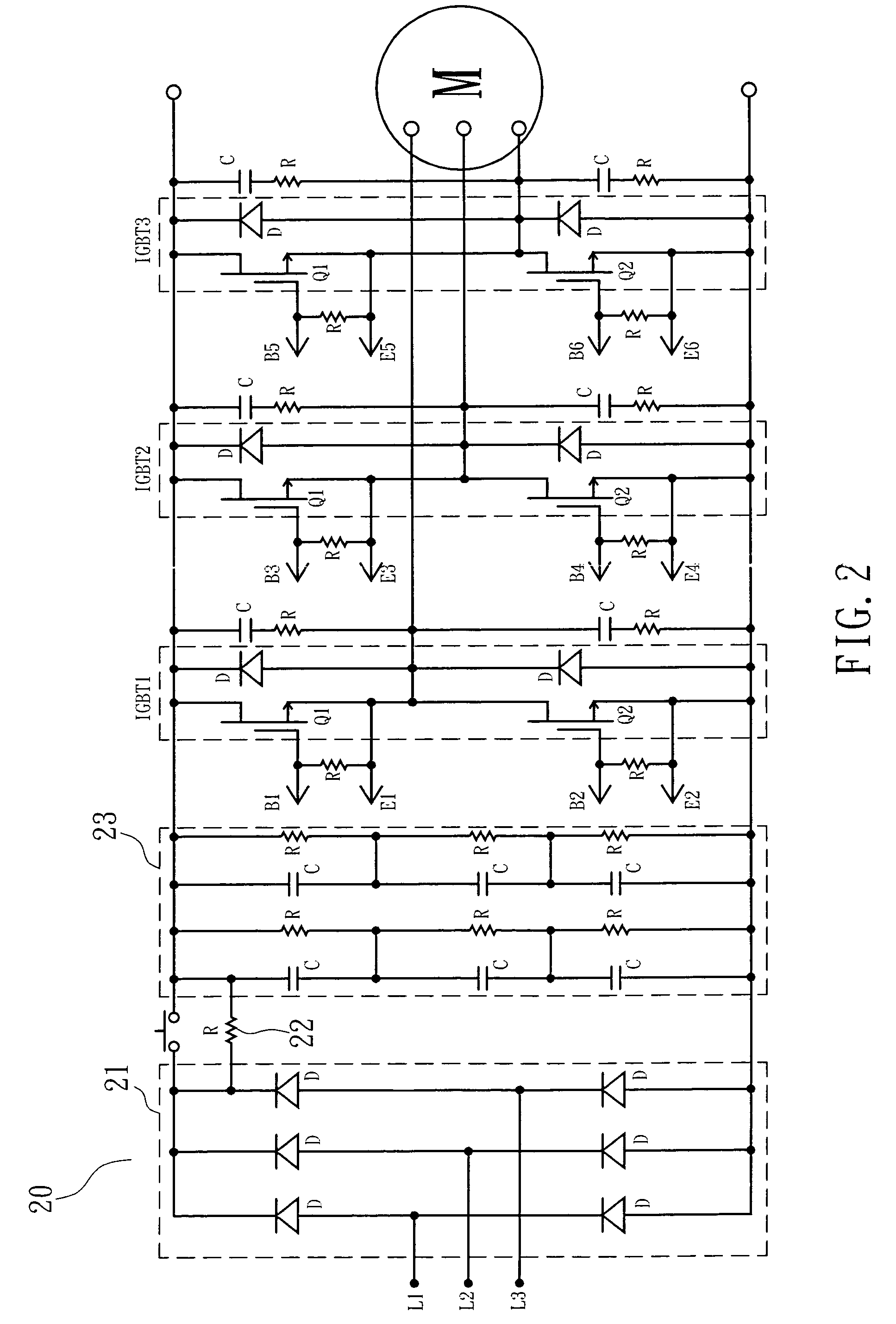

[0016]Referring to FIGS. 1˜8, a linear motor automatic control circuit assembly is connected to a 3-phase linear motor M that is adapted to drive a submersible oil pump of an artificial oil lift system. The linear motor automatic control circuit assembly comprises a linear motor power supply circuit 20, a CPU 30, an insulated gate bipolar transistor driving circuit 40, a current detection circuit 50, a fluid depth sensor 110, a function setting and status display circuit 100, and a circuit assembly power supply circuit 60. The linear motor power supply circuit 20 is comprised of a 3-phase rectifier 21, a charging resistor 22, a filter 23 and insulated gate bipolar transistors IGBT1, IGBT2 and IGBT3, and adapted to provide power supply to the linear motor M. The insulated gate bipolar transistor driving circuit 40 is electrically connected between the CPU 30 and the insulated gate bipolar transistors IGBT1, IGBT2 and IGBT3 of the linear motor power supply circuit 20, and adapted to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com