High capacity shear mechanism

a high-capacity, shear mechanism technology, applied in the direction of draw-gear, railway components, railway coupling accessories, etc., can solve the problems of high repair cost and premature failure of prior-art emergency release mechanisms, and reduce the number of premature failures , the effect of reducing the amount of fatigu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

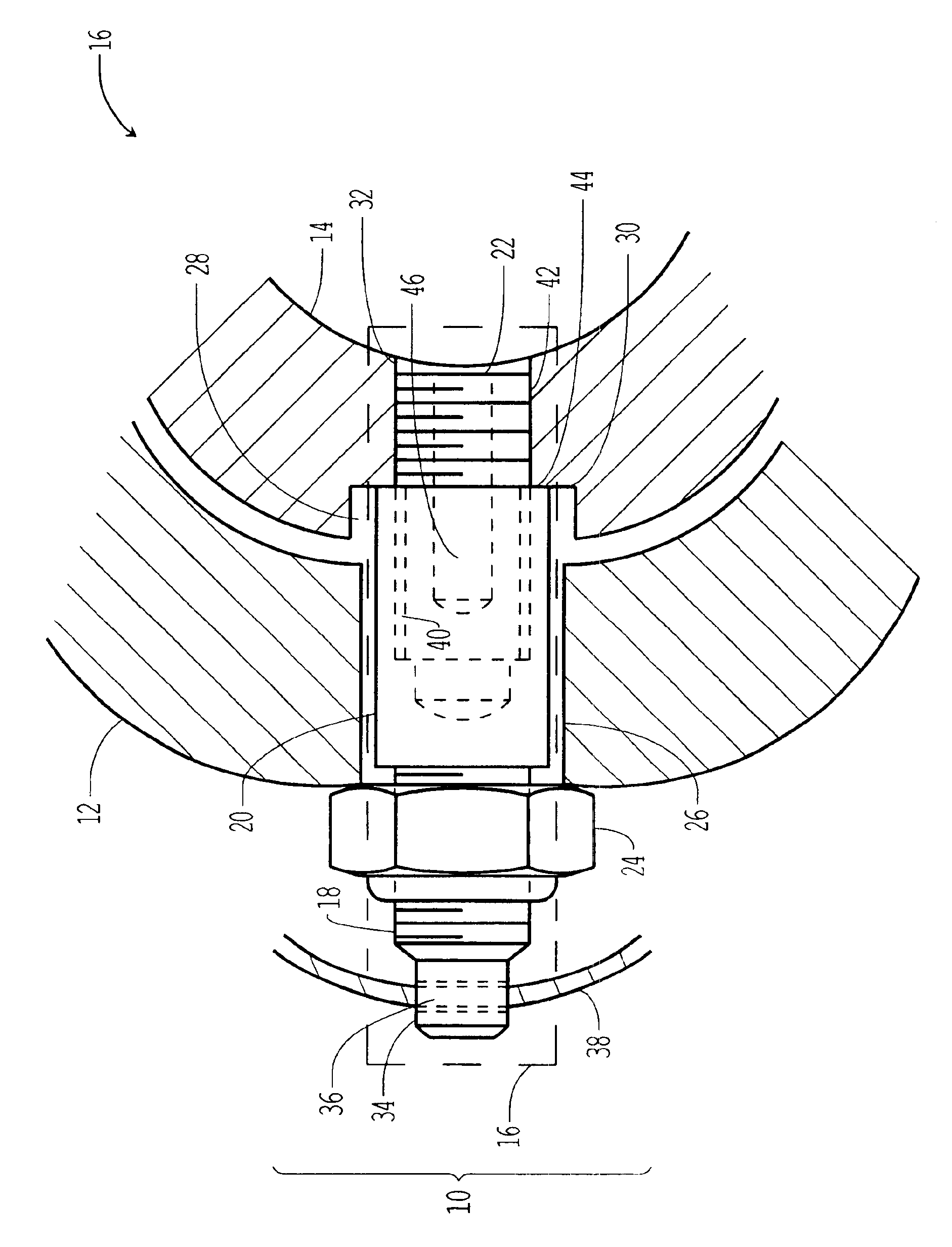

[0014]Turning now to the drawing, the sole FIGURE shows an emergency release mechanism 10 together with a drawbar body 12 and a release rail 14 and are shown generally as 16. The emergency release mechanism 10, in the preferred embodiment, consists of a fastener stud such as a two sided threaded stud 16, having a first threaded end 18, a cylindrical body 20 and a second threaded end 22, together with a fastener such as a lock nut 24, a through hole 26 in the drawbar body 12, a recess 28 having a machined surface 30 in the release rail 14, an aperture such as a tapped opening such as a threaded hole 32 in the release rail 14, the rim of which is located in the recess 28, and a chamfered dowel extension 34 of the first threaded end 18 having a hole 36 there through. A retaining wire 38 passes through the hole 36.

[0015]The dowel extension 34 is flattened such that a wrench interface is formed so that a wrench can be used on the dowel extension 34 to screw the second threaded end 22 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com