Hollow composite products and method for making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

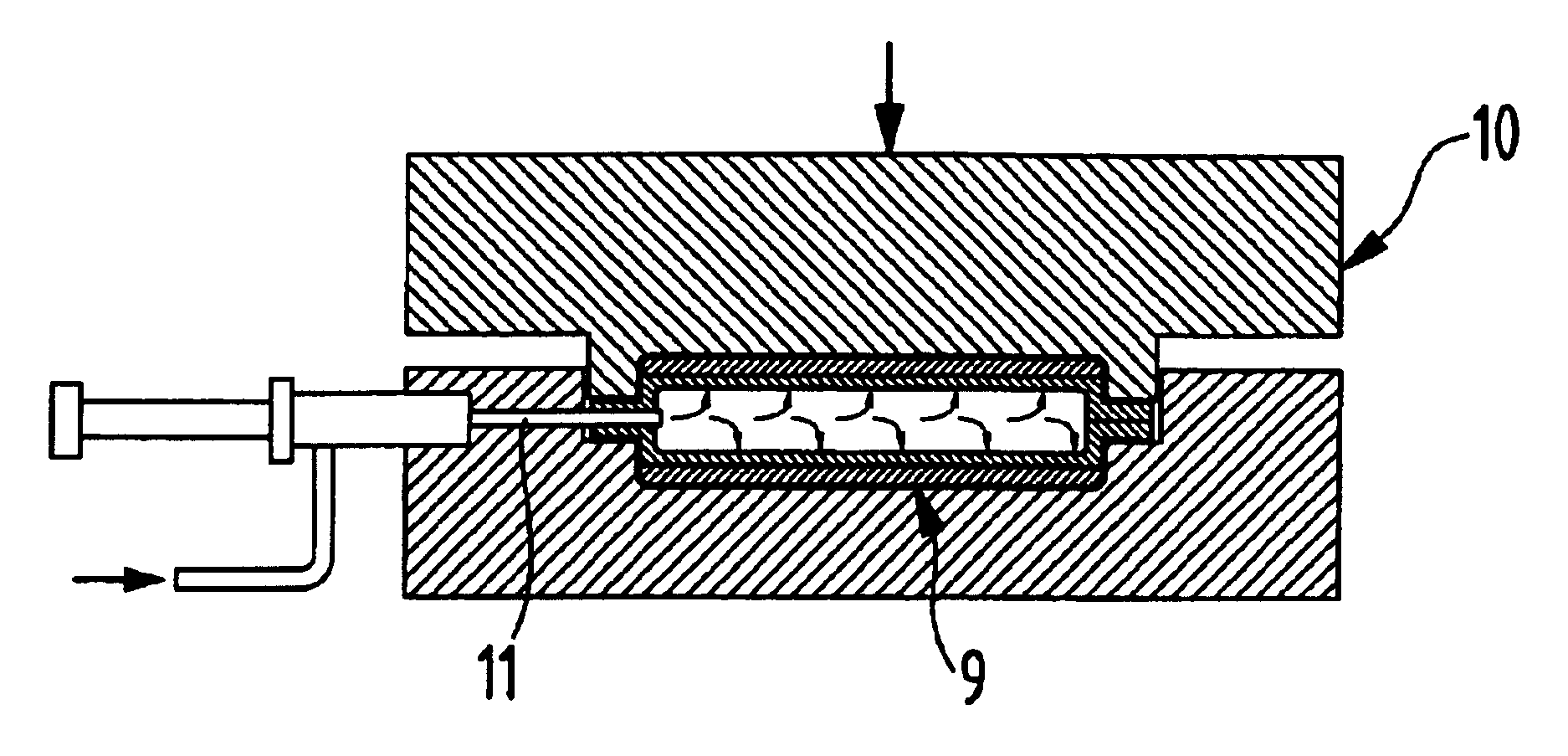

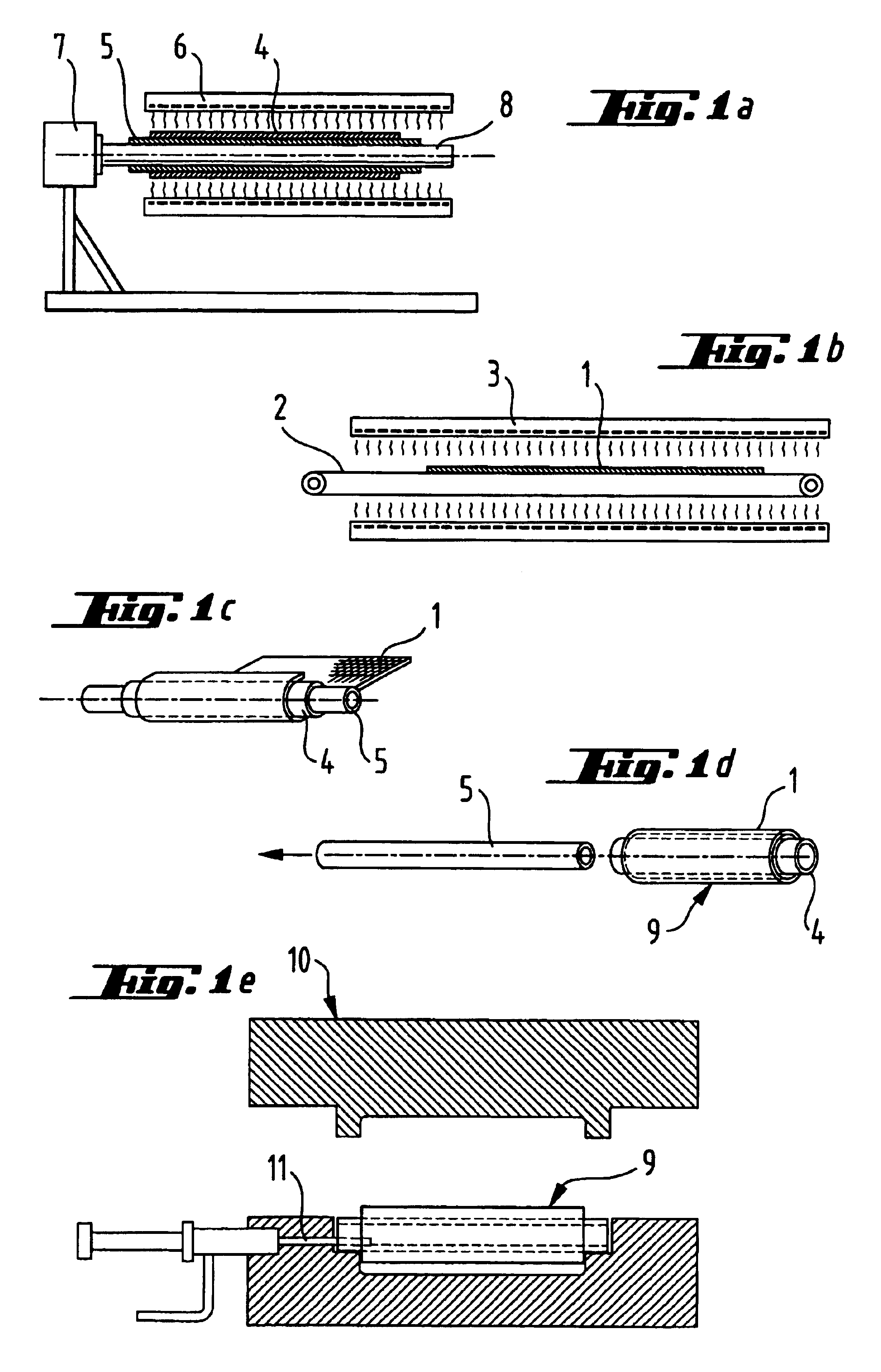

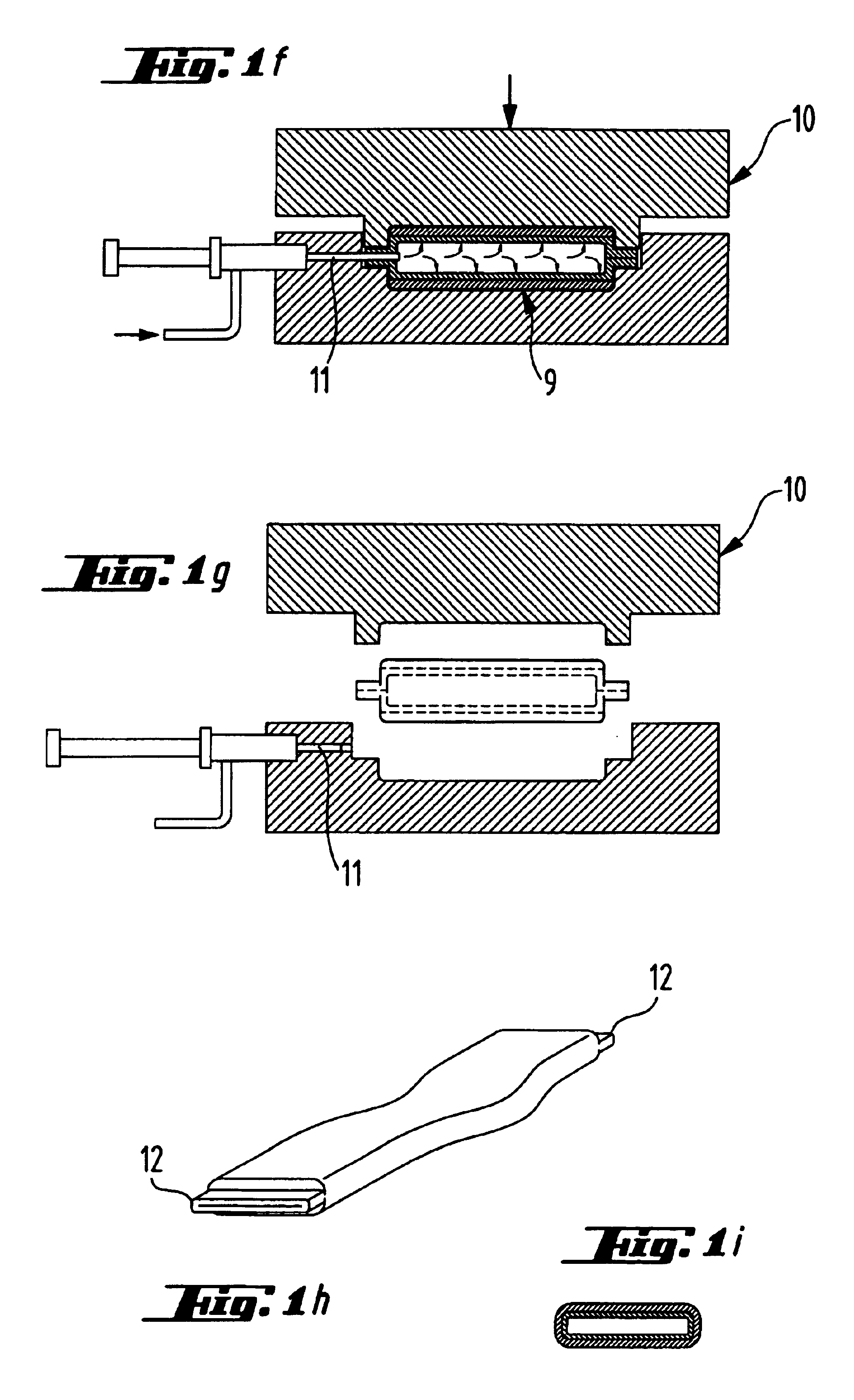

[0044]Parts (a), (b), (c), (d), (e), (f) and (g) in FIG. 2 are a very diagrammatic depiction of the various stages of the method according to the present invention. In this method, a woven 20 consisting of composite glass / organic thermoplastic yarns and lined on one of its faces with a leaktight film 21 (part a in FIG. 2) is placed on a support 22 and is then preheated in an oven 23 (part b) before being rolled up on itself so that the film is on the inside (part c). The preheated woven / film assembly 24 is placed in a heated compression mould 25. A needle 26 is then introduced into the assembly (part d), and once the mould has been closed, air is injected at a pressure in excess of 40 bar (part e). Once the moulded component has solidified, the air is removed, the mould is opened and the composite component is withdrawn from the mould (part f). This then, for example, yields the component, the cross section of which is depicted as part g.

third embodiment

[0045]Parts (a), (b), (c), (d), (e), (f) and (g) in FIG. 3 are a very diagrammatic depiction of the various stages of the method according to the present invention. In this method, two wovens 30, of the kind depicted in Figure a, these wovens each consisting of composite glass / organic thermoplastic yarns and each lined on one of their sides with a leaktight film 31 are placed on a support 32 then preheated in an oven 33 (part b). On leaving the oven (part c), the wovens are joined in such a way that the films face each other and thus form the leaktight inflatable bag (the edges 34 of the wovens being held joined together during moulding so as to ensure leaktightness) and the preheated wovens with films assembly is placed in a heated compression mould 35. A needle 36 is then introduced into the assembly (part d) and after the mould has been closed, air is injected at a pressure in excess of 40 bar (part e) After the moulded component has solidified, the air is removed, the mould is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com