Sewing machine needle

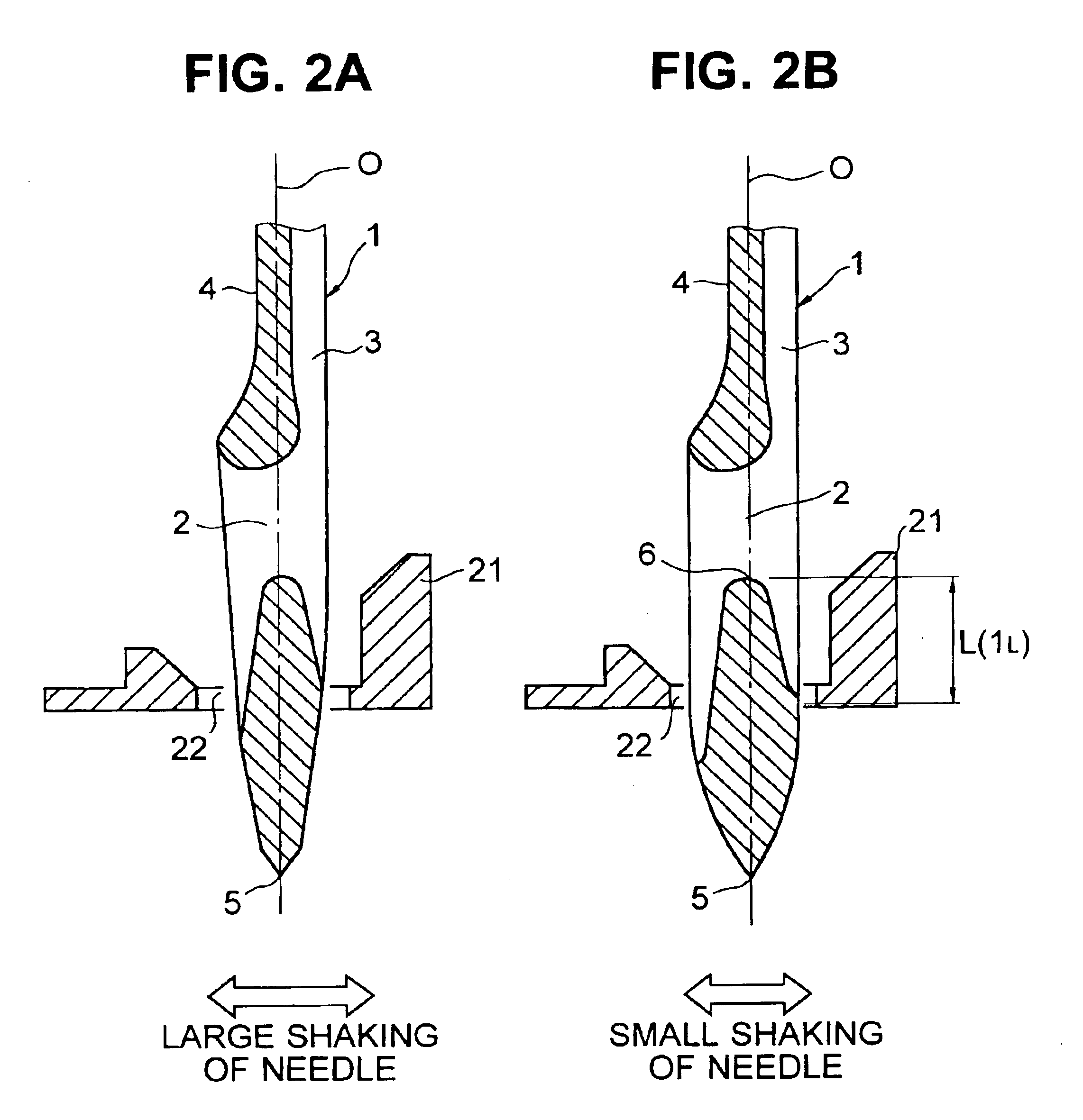

a sewing machine needle and needle technology, applied in sewing needles, sewing apparatus, textiles and papermaking, etc., can solve the problems of large needle shaking, prone to stitch skipping, and easy instability of seams, so as to prevent stitch skipping and fabric yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]A preferred embodiment of the present invention will now be described with reference to the drawings.

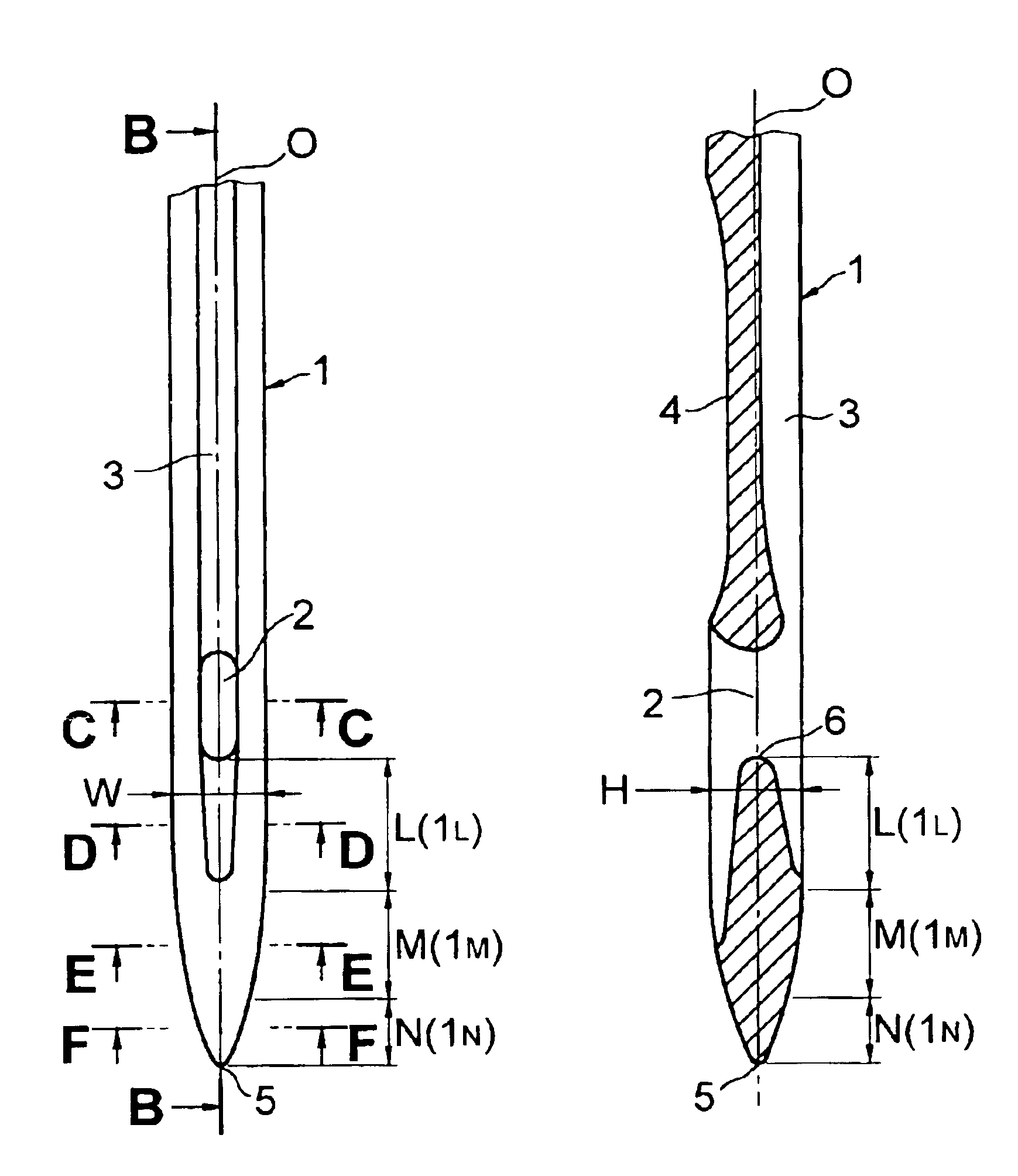

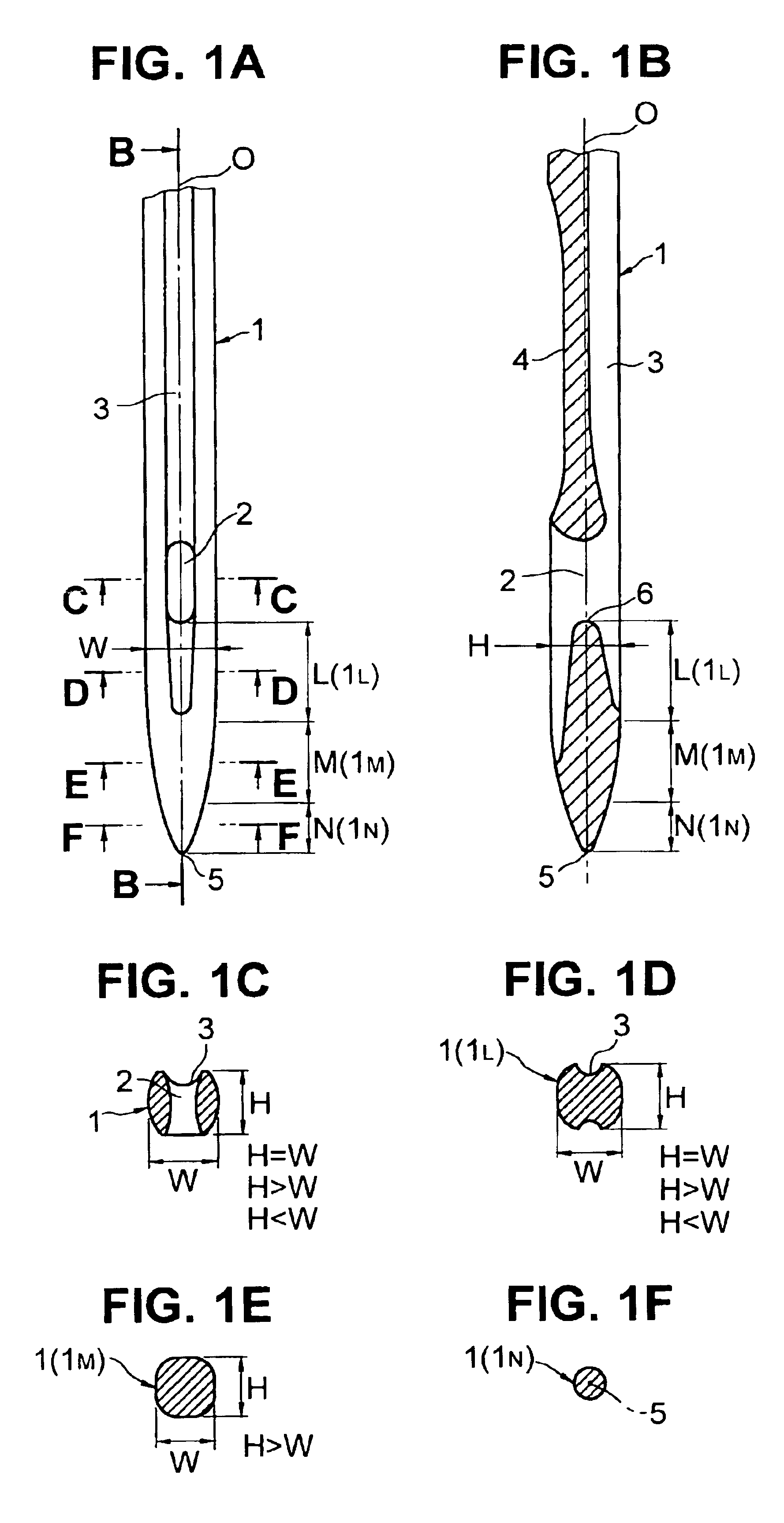

[0022]Referring first to FIGS. 1A to 1F, an embodiment of a sewing machine needle in accordance with the present invention is illustrated.

[0023]In the figures, reference numeral 1 denotes a blade, reference numeral 2 denotes a needle eye formed at a distal end portion of the blade 1 in the vicinity to a needle point 5, reference numeral 3 denotes a long groove formed along the front side of the blade surface, and reference numeral 4 denotes a scarf . The sewing machine needle according to the embodiment is configured as shown in FIG. 1B such that over a predetermined length L from an edge 6, closer to the needle point 5, of the needle eye 2 toward the needle point 5, the blade 1 has a straight profile (i.e., thickness H=constant) extending parallel to a longitudinal axis O of the needle as viewed from a side of the needle in a direction orthogonal to a direction in which the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com