Miniaturized microwave antenna

a microwave antenna and miniaturized technology, applied in the direction of resonant antennas, substantially flat resonant elements, elongated active element feed, etc., can solve the problems of expensive contacts, inability to directly solder .lambda./4 monopoles to printed circuit boards, and considerable disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

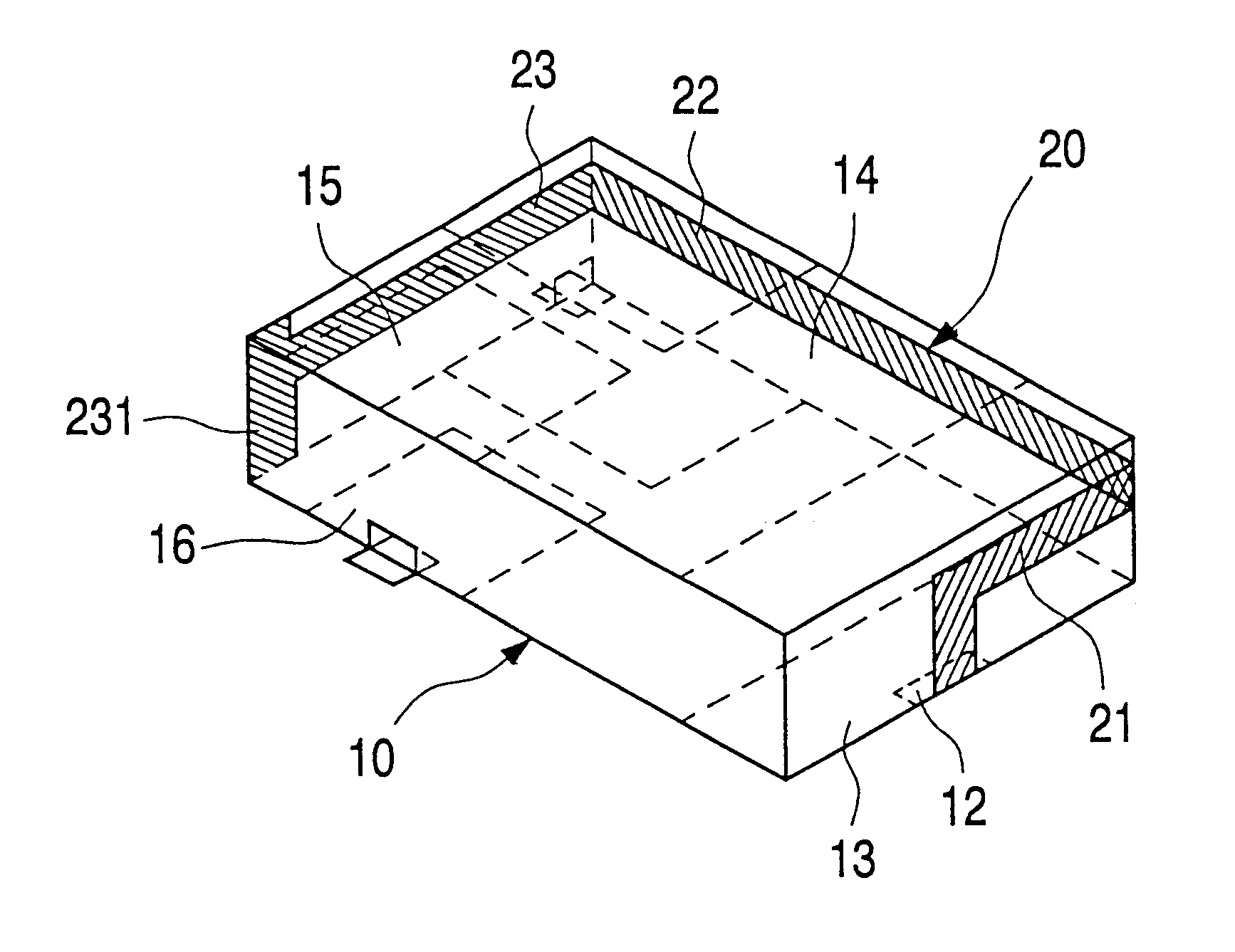

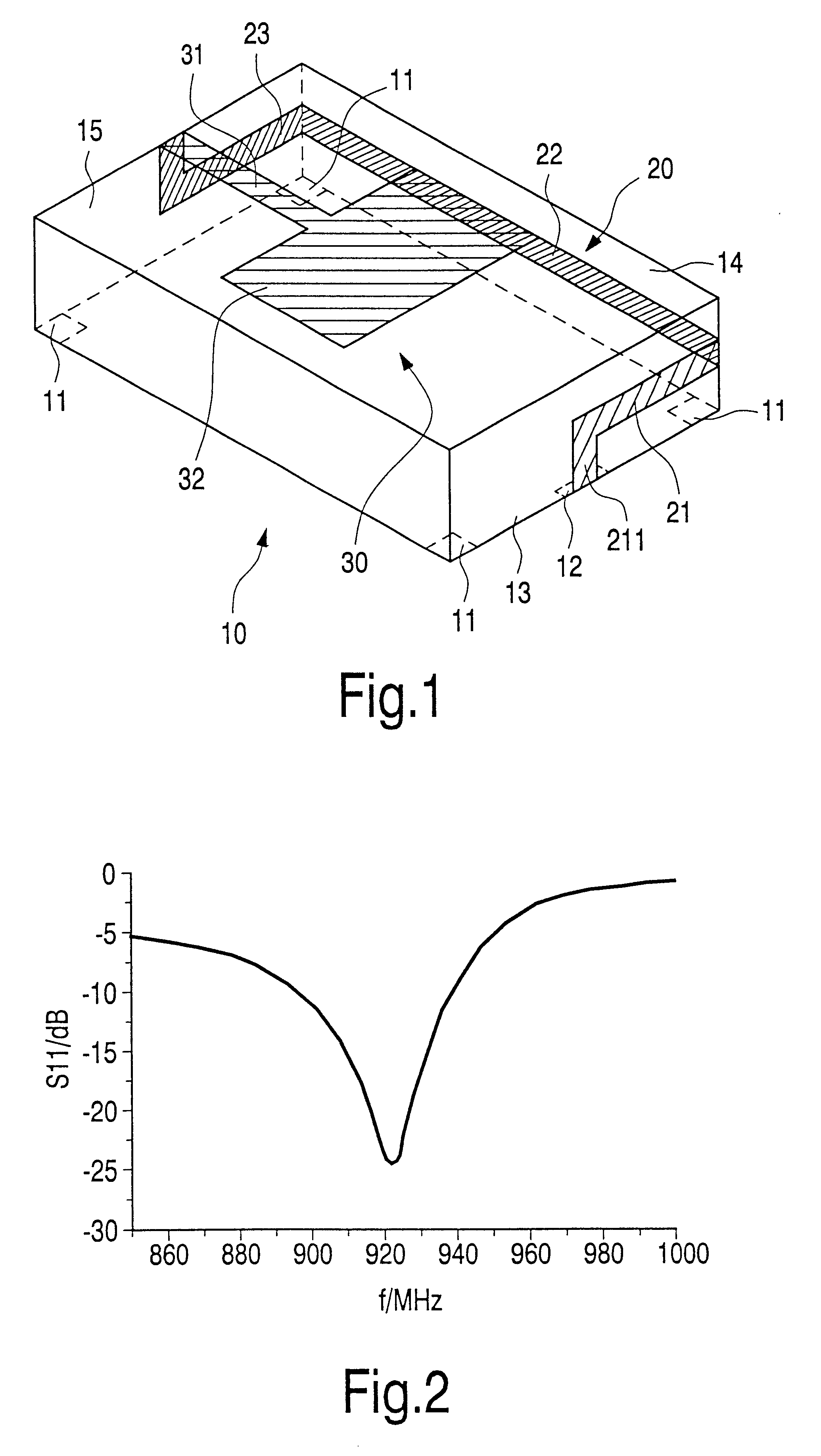

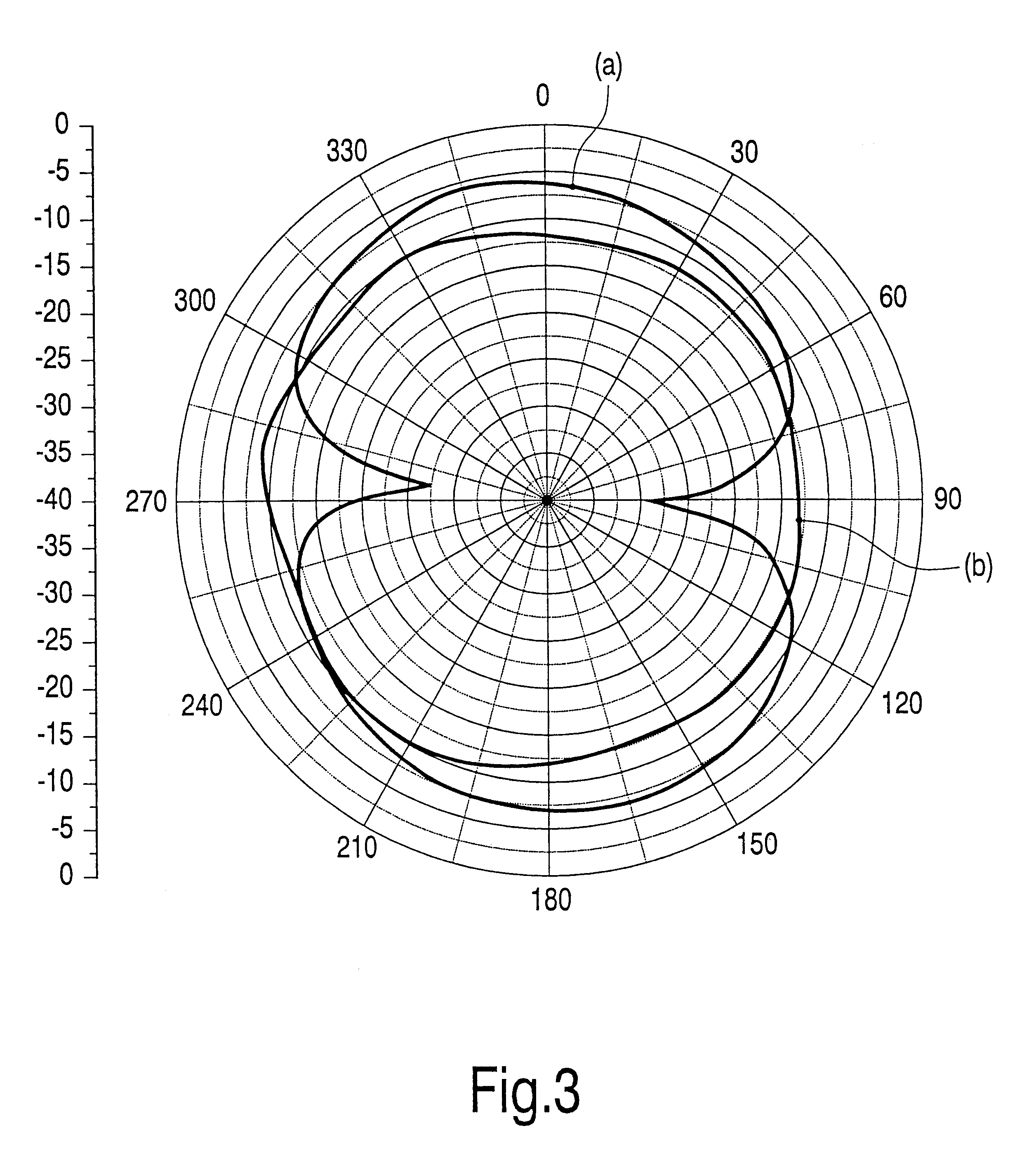

More in detail, a first embodiment shown in FIG. 1 shows a rectangular block-shaped substrate 10 with a resonant conductor track structure 20, 30. The substrate 10 is provided with several soldering points 11, by which it can be soldered on a printed circuit board by surface mounting (SMD technology), at the corners of its lower surface. Furthermore, a feed terminal 12 is present at the lower side in the central region of a first side face 13 in the form of a metallization pad which is soldered to a corresponding conductor region on a printed circuit board during mounting and through which the antenna is supplied with electromagnetic energy to be radiated. Starting from the feed terminal 12, a first portion 21 of a conductor track 20 extends vertically to approximately halfway the height of the first side face 13 and then continues in horizontal direction along the first side face 13 to a second side face 14. The conductor track then continues in horizontal direction along the secon...

second embodiment

This second embodiment of the antenna can also be mounted on a printed circuit board by surface mounting (SMD technology). Furthermore, a very homogeneous, quasi-omnidirectional space pattern both in horizontal direction and in the direction perpendicular thereto can be achieved again.

It was also found that two resonance frequencies are excited if the two metallization structures 30, 40 are slightly different, i.e. have different lengths or widths, with different couplings (for example by a gap 211 of variable width and / or length) to the joint conductor track 20, or with different dimensions of the first and second metallization pads 33, 43, which frequencies are mutually shifted in accordance with these differences. In that case, for example, the first metallization structure 30 will have a somewhat lower resonance frequency than the second metallization structure 40.

The number of these resonances can be increased in that, for example, one or several further substrates with identic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com