Heat exchanger, method of manufacturing the same, and air-conditioning apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

200>

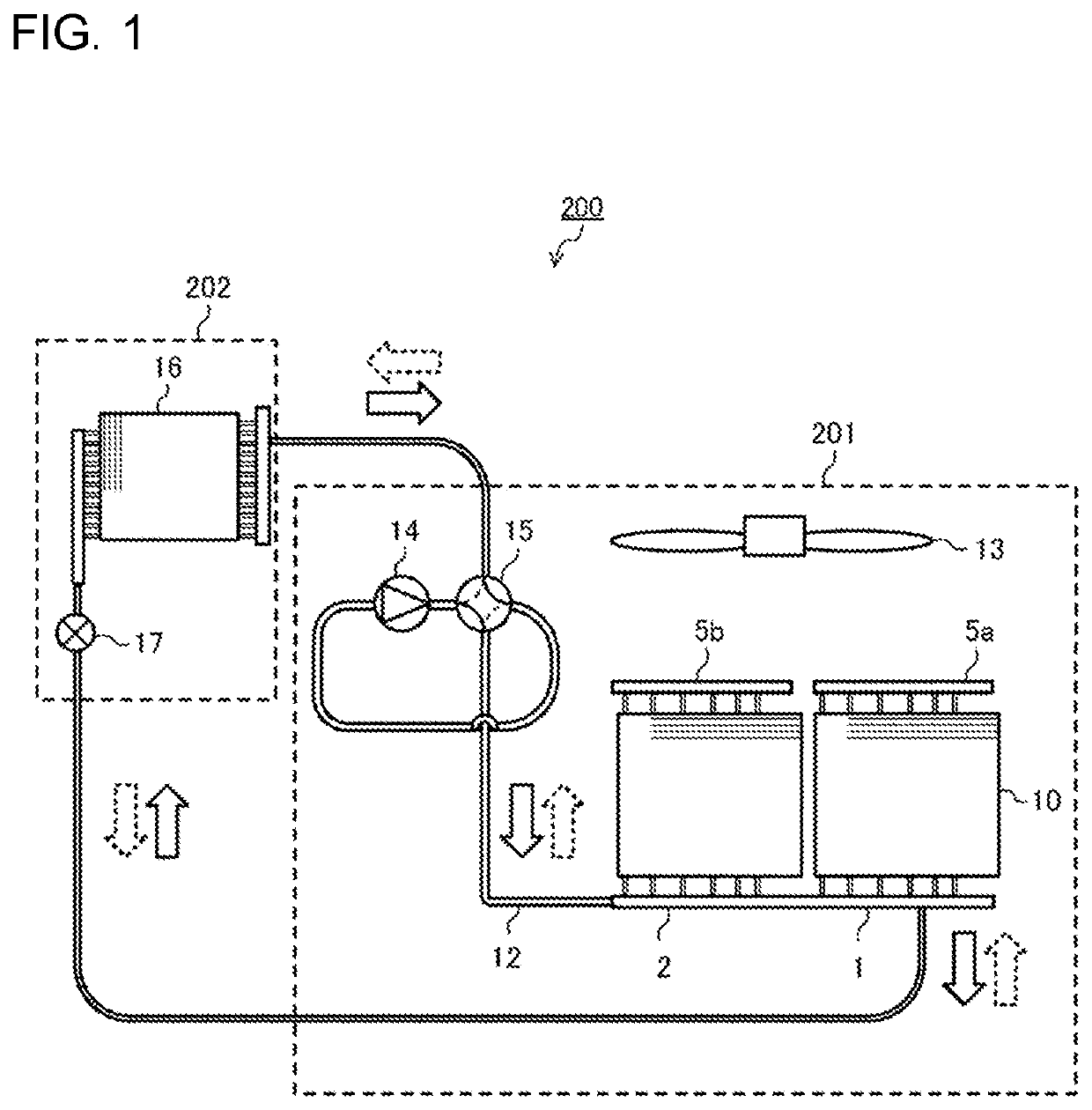

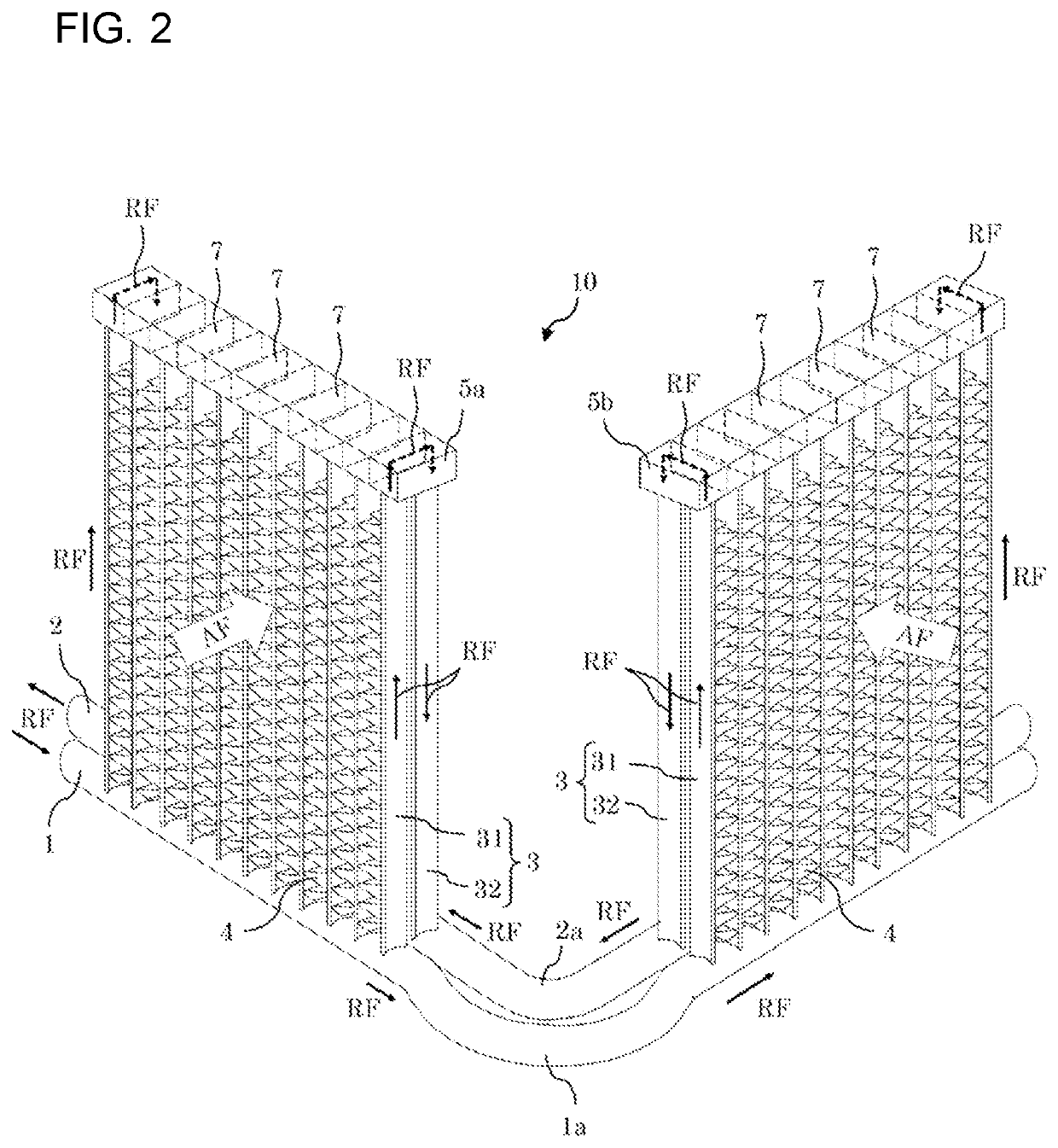

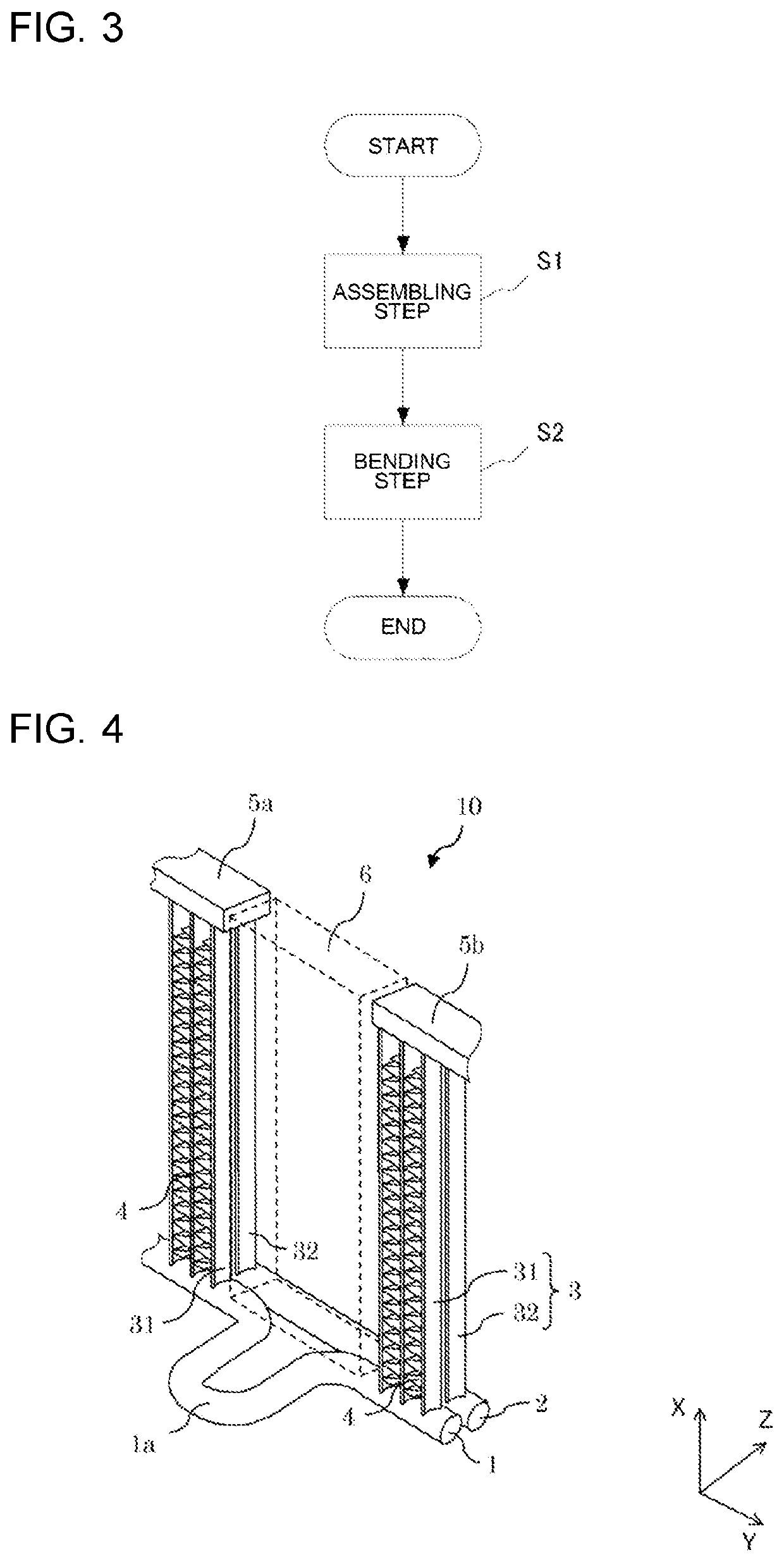

[0031]An air-conditioning apparatus according to Embodiment 1 will be described first. FIG. 1 is a refrigerant circuit diagram illustrating an example of an air-conditioning apparatus 200 according to Embodiment 1. In FIG. 1, solid-line outlined arrows represent the flow of refrigerant in a cooling operation, and broken-line outlined arrows represent the flow of the refrigerant in a heating operation.

[0032]As illustrated in FIG. 1, the air-conditioning apparatus 200 includes an outdoor unit 201 and an indoor unit 202. The outdoor unit 201 includes a heat exchanger 10, used as an outdoor heat exchanger, an outdoor fan 13, a compressor 14, and a four-way valve 15. The indoor unit 202 includes an indoor heat exchanger 16, an expansion device 17, and an indoor fan (not illustrated). The heat exchanger 10, the compressor 14, the four-way valve 15, the indoor heat exchanger 16, and the expansion device 17 are connected by refrigerant pipes 12, thus forming a refrigerant circuit.

[0033]...

embodiment 2

[0067]A heat exchanger 10 according to Embodiment 2 of the present disclosure will be described below. FIG. 6 is a perspective view of the heat exchanger 10 according to Embodiment 2 in the pre-bending state. FIG. 7 is a perspective view of the heat exchanger 10 according to Embodiment 2 in the post-bending state.

[0068]In Embodiment 2, the first header 1 in Embodiment 1 is partly modified. The heat exchanger 10 and an air-conditioning apparatus 200 in Embodiment 2 have the same configurations as those in Embodiment 1, and explanation of the configurations is omitted. The same components or equivalents are designated by the same reference signs.

[0069]For the stress-absorbing part 1a of the heat exchanger 10 according to Embodiment 2, as illustrated in FIGS. 6 and 7, the stress-absorbing part 1a of the first header 1 is curved in the first direction X. Specifically, the stress-absorbing part 1a of the first header 1 in Embodiment 2 is curved toward the third headers 5a and 5b, or upwa...

embodiment 3

[0072]A heat exchanger 10 according to Embodiment 3 of the present disclosure will be described below. FIG. 8 is a plan view of the heat exchanger 10 according to Embodiment 3 in the pre-bending state.

[0073]In Embodiment 3, the first header 1 in Embodiment 1 is partly modified. The heat exchanger 10 and an air-conditioning apparatus 200 in Embodiment 3 have the same configurations as those in Embodiment 1, and explanation of the configurations is omitted. The same components or equivalents are designated by the same reference signs.

[0074]In Embodiment 3, as illustrated in FIG. 8, the first header 1 of the heat exchanger 10 includes two segments located on opposite sides of the bending target portion 6 (refer to FIG. 4). The stress-absorbing part 1a is a separate coupling that couples facing ends of the segments of the first header 1, or a first end 1b and a second end 1c. In this case, the first and second ends 1b and 1c of the first header 1, the stress-absorbing part 1a, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com