Self-Sealing Closure System and Method

a self-sealing, closure system technology, applied in the direction of slide fasteners, protective garments, other accessories, etc., can solve the problems of system not providing an effective sealing connection, lack of integrity, and redundancy but not necessarily integrity of the whole, and achieves high flexibility, high flexibility, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]As used herein, the terms “top” and “bottom” are intended as relative only in respect to describing the configuration of parts of the invention and have no relationship to gravitational position. Likewise, the term “plane”, as in “common joining plane” is intended to describe only the relative juxtaposition of parts in a static state, in lieu of a continuing geometric abstraction, thus the effective joining plane of the generally elastic and flexible structures may bend or twist relative to common orthogonal orientation. The term “elastomeric” is intended to include a selection or rubber-like materials which are both flexible and resilient with sufficient shape memory to function as designed. The term “containment device” is intended to include a wide range of bags, boxes, luggage, and similar devices.

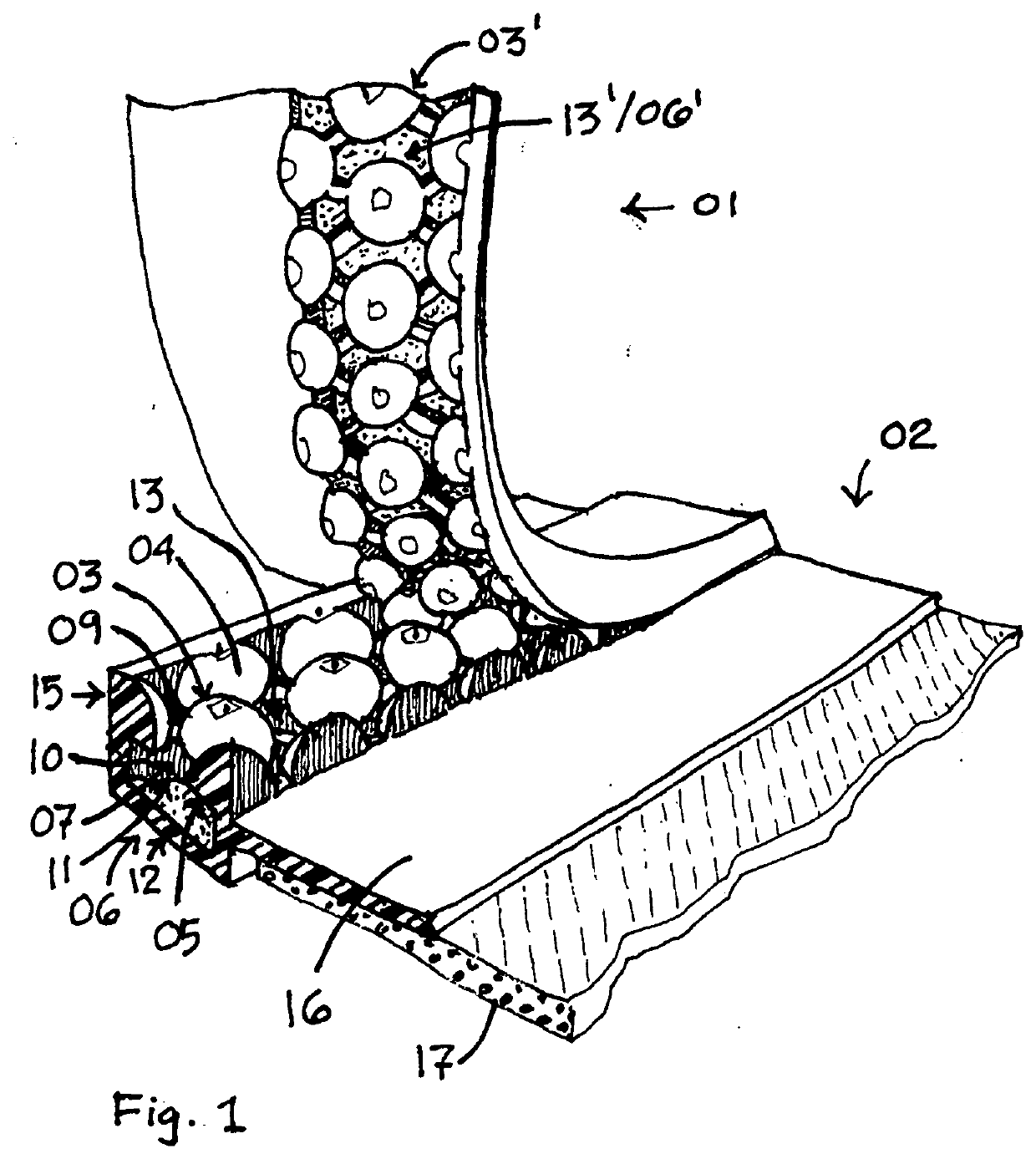

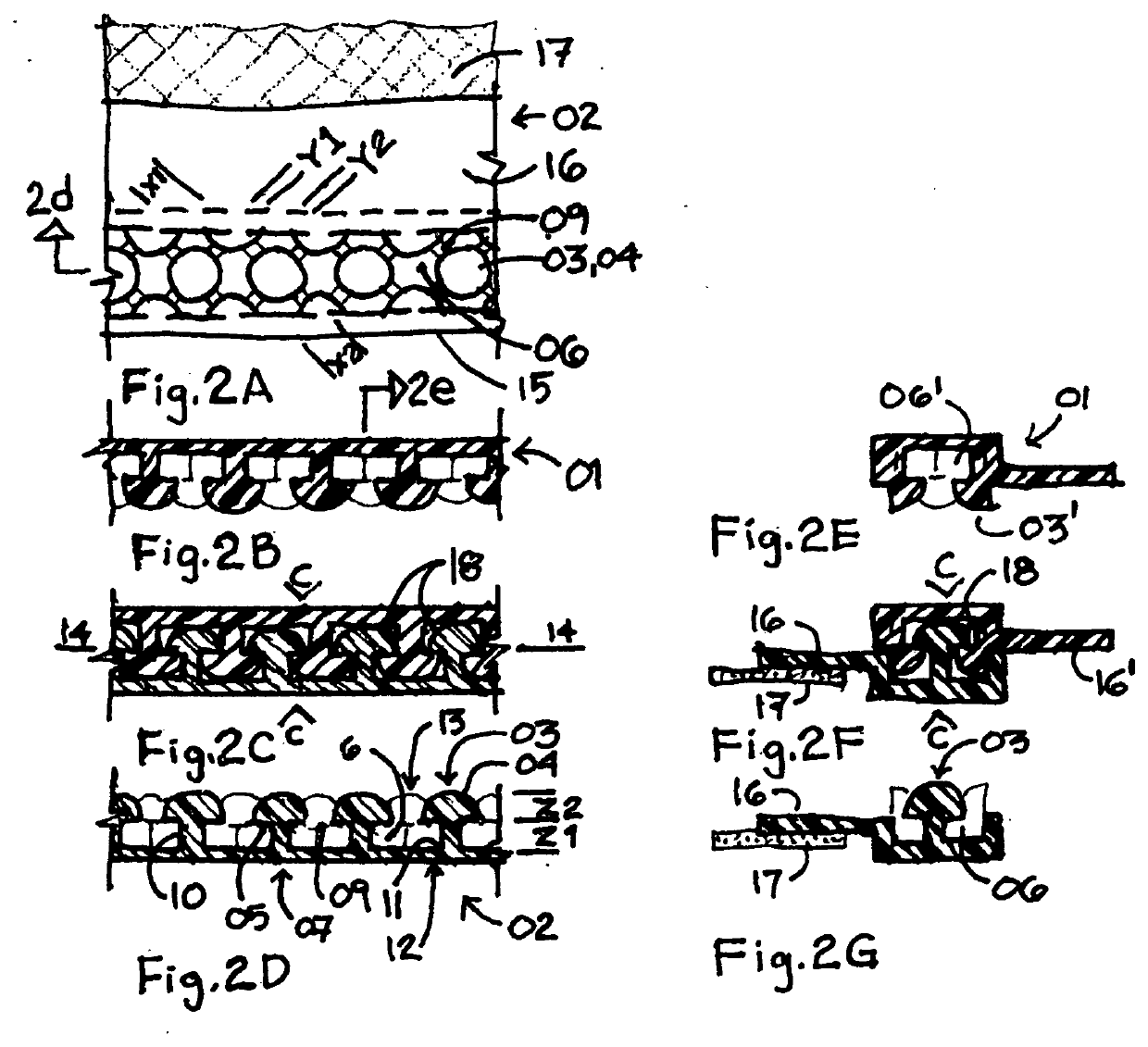

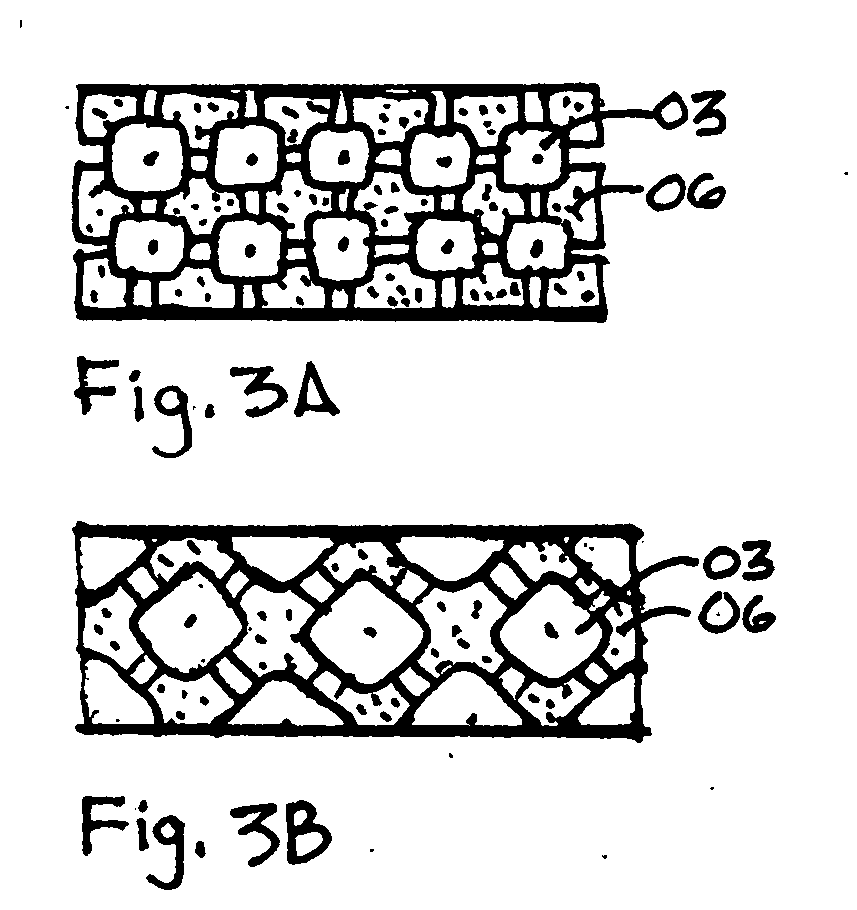

[0041]As schematically illustrated in FIGS. 1 and 2 the Self-Sealing Closure System includes a first portion 01 for interconnecting with a second portion 02, the portions being e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com