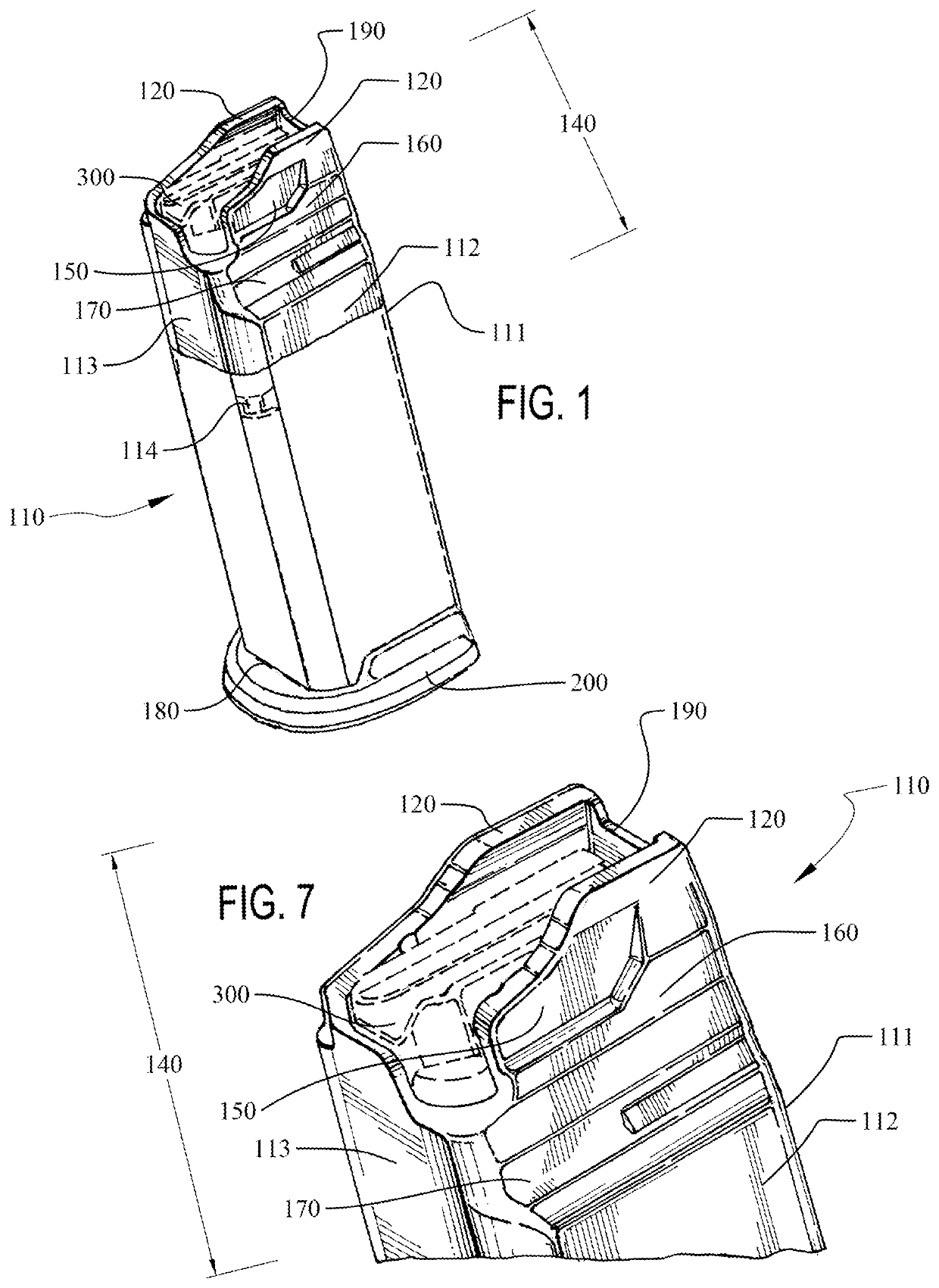

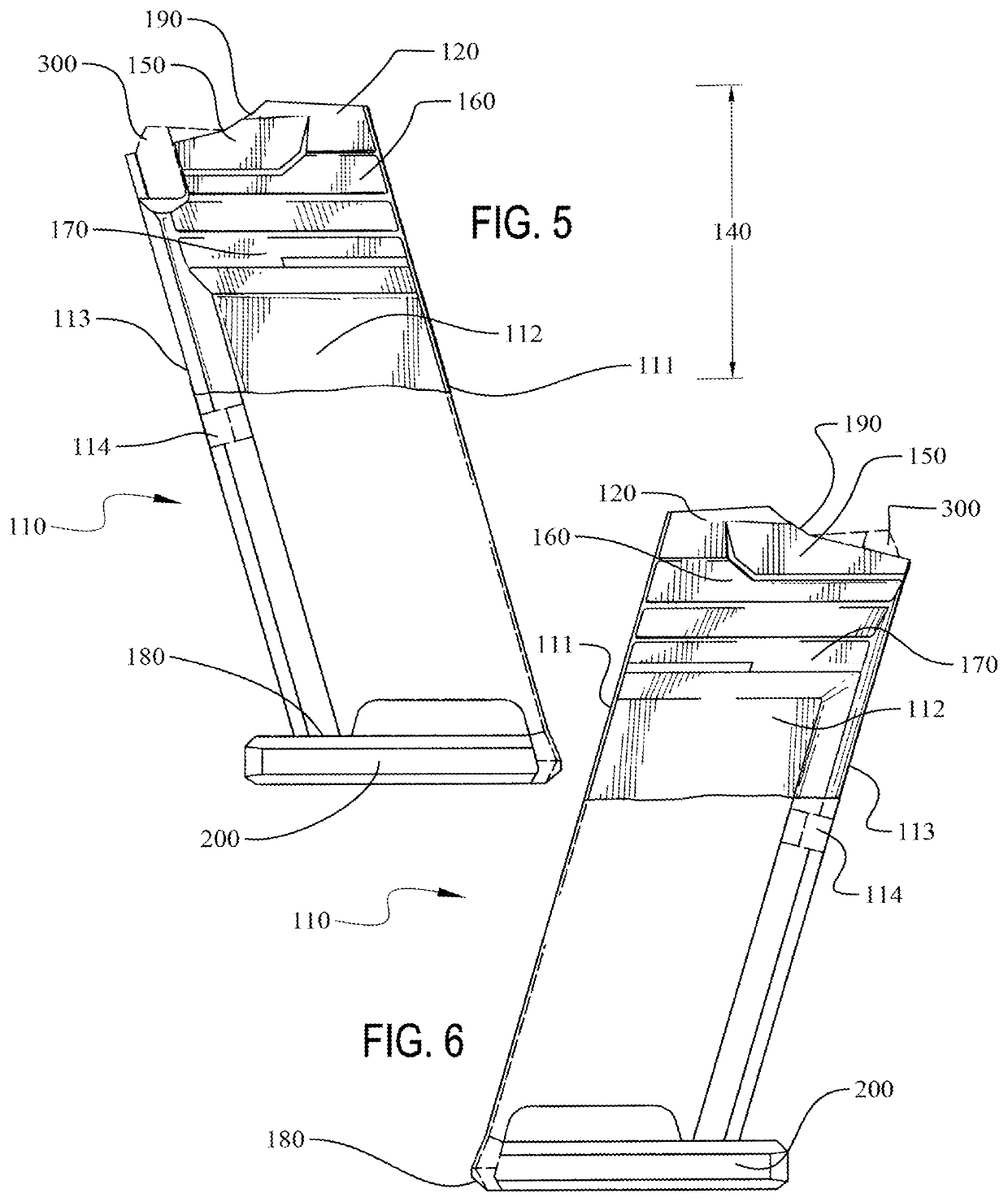

Ammunition Magazine

a technology for ammunition magazines and magazines, applied in the field of ammunition magazines, can solve the problems of unsatisfactory performance of magazines and/or the firearms in which they are used, preventing the use of polymers for magazines of some weapon platforms, and general problems with the use of polymer magazine bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]It should be noted that this disclosure includes a plurality of embodiments, with a plurality of elements and aspects, and such elements and aspects need not necessarily be interpreted as being conjunctively required by one or more embodiments of the present invention. Rather, all combinations of the one or more elements and / or aspects can enable a separate embodiment of the present invention, which may be claimed with particularity in this or any one or more future filed Non-Provisional patent applications. Moreover, any particular materials, structures, and / or sizes disclosed herein, whether expressly or implicitly, are to be construed strictly as illustrative and enabling, and not necessarily limiting. Therefore, it is expressly set forth that such materials, structures, and / or sizes independently or in any combination thereof, are merely illustratively representative of one or more embodiments of the present invention and are not to be construed as necessary in a strict se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com