Zinc or zinc alloy electroplating method and system

a zinc or zinc alloy and electroplating bath technology, applied in the direction of electroplating, etc., can solve the problems of poor adhesion, inability to carry out good zinc rust-inhibiting plating, and electroplating by using an alkaline zinc nickel alloy plating bath encounters a problem, etc., to achieve economic plating, maintain the performance of the zinc or zinc alloy electroplating bath, and prolong the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

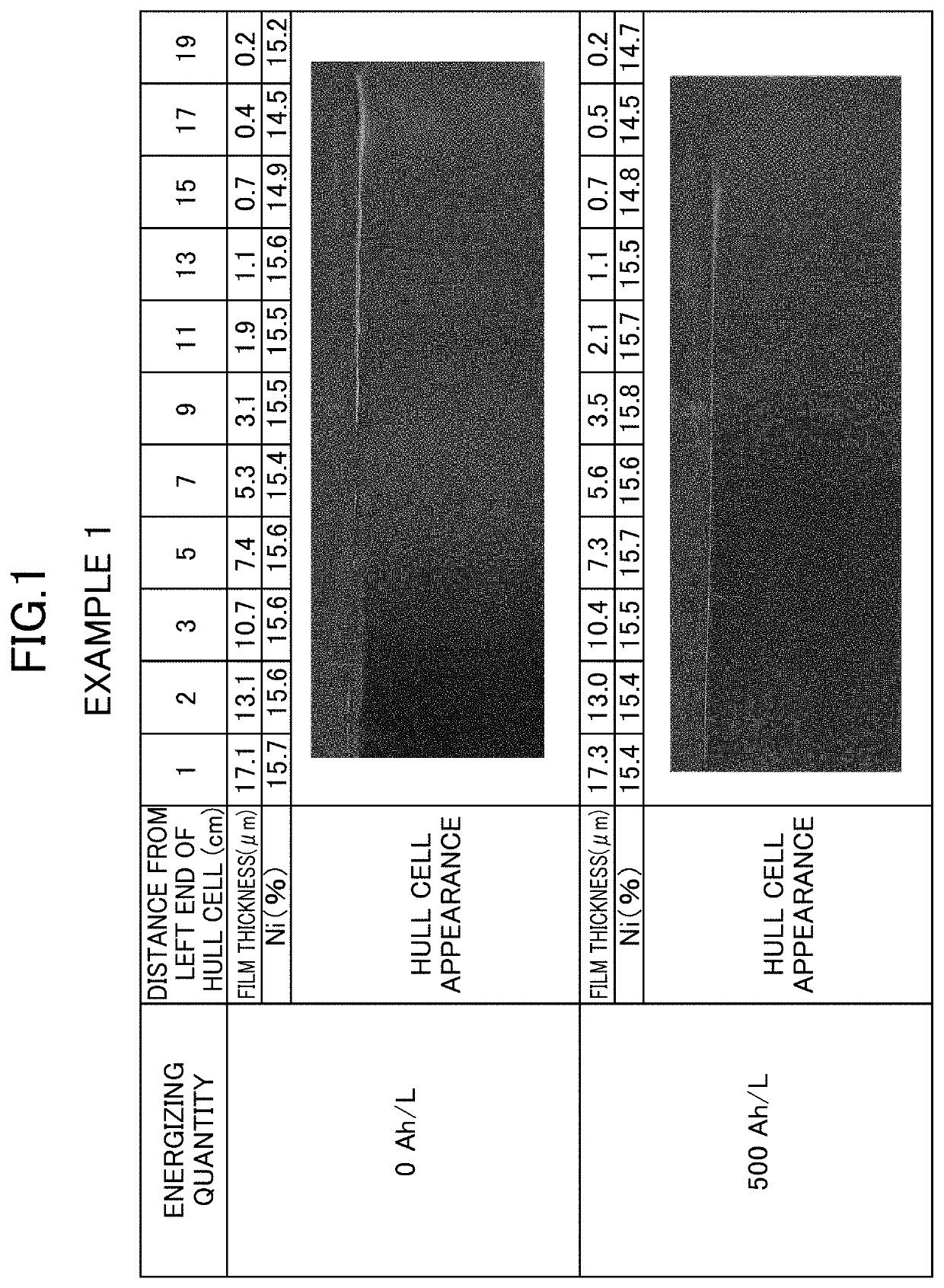

example 1

[0083]An anode plate (surface roughness Ra: 4 μm, 64×64×2 mm) coated with tantalum oxide in a thickness of 0.5 to 0.8 μm on Ni was used and an alkaline zinc nickel alloy plating bath shown below was used (500 mL) to carry out zinc nickel alloy plating with energizing of 500 Ah / L. The pore diameter in the coating film was 0.1 to 1 μm, and the drag-out of the plating bath was set to 2 mL / Ah. The cathode current density was 4 A / dm2, the anode current density was 9.8 A / dm2, and the plating bath temperature was 25° C. The plating bath was cooled to maintain 25° C. An iron plate was used as the cathode. Note that the iron plate of the cathode was replaced for each 16 Ah / L during the energizing. The zinc ion concentration of the plating bath was kept constant by immersion and dissolution of the metal zinc. The nickel ion concentration of the plating bath was kept constant by replenishing a nickel replenishment agent IZ-250YNi (manufactured by Dipsol). The caustic soda concentration of the ...

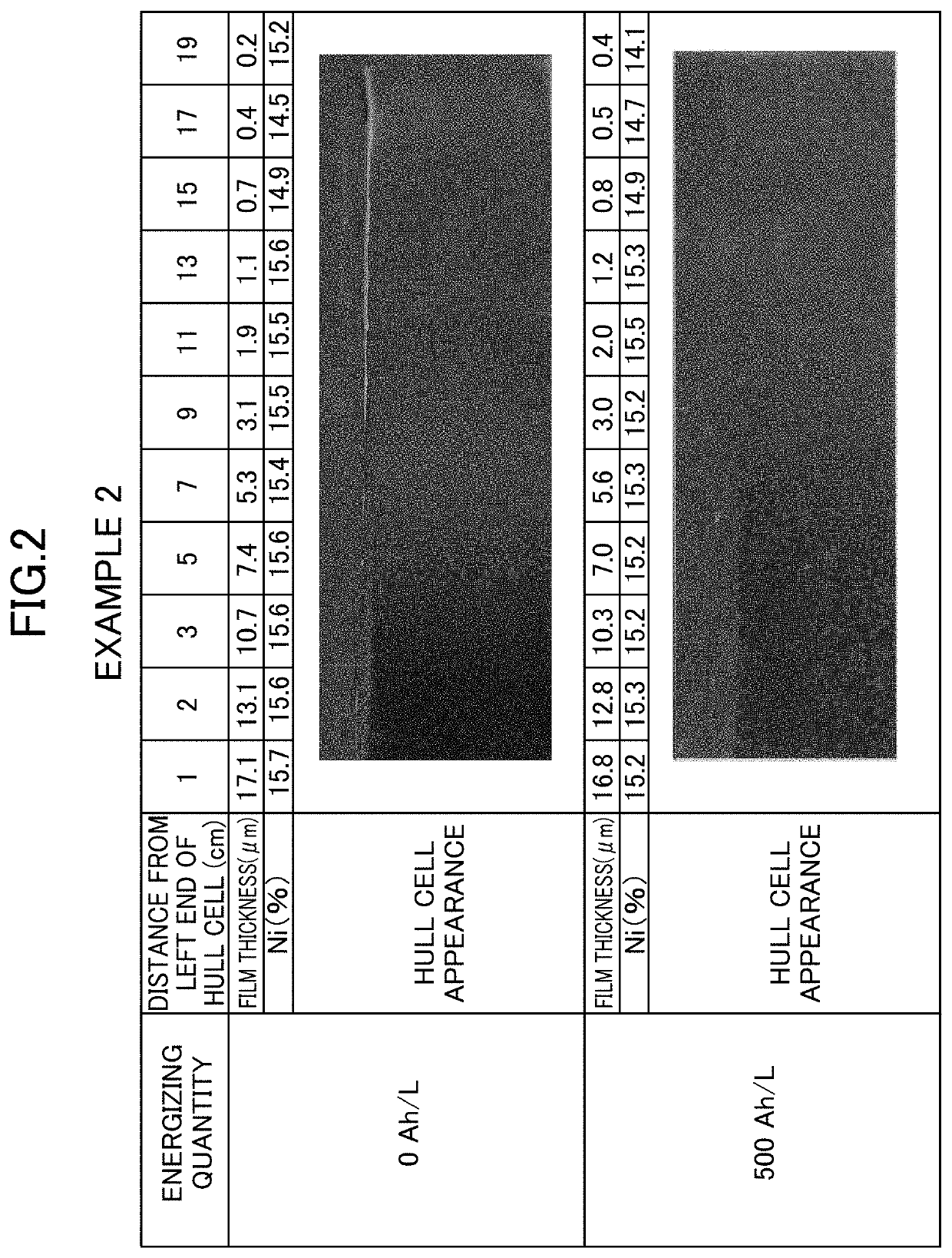

example 2

[0090]An anode plate (surface roughness Ra: 4 μm, 64×64×2 mm) coated with tantalum oxide in a thickness of 0.5 to 0.8 μm on Fe was used and an alkaline zinc nickel alloy plating bath shown below was used (500 mL) to carry out zinc nickel alloy plating with energizing of 500 Ah / L. The pore diameter in the coating film was 0.1 to 1 μm, and the drag-out of the plating bath was set to 2 mL / Ah. The cathode current density was 4 A / dm2, the anode current density was 9.8 A / dm2, and the plating bath temperature was 25° C. The plating bath was cooled to maintain 25° C. An iron plate was used as the cathode. Note that the iron plate of the cathode was replaced for each 16 Ah / L during the energizing. The zinc ion concentration of the plating bath was kept constant by immersion and dissolution of the metal zinc. The nickel ion concentration of the plating bath was kept constant by replenishing a nickel replenishment agent IZ-250YNi (manufactured by Dipsol). The caustic soda concentration of the ...

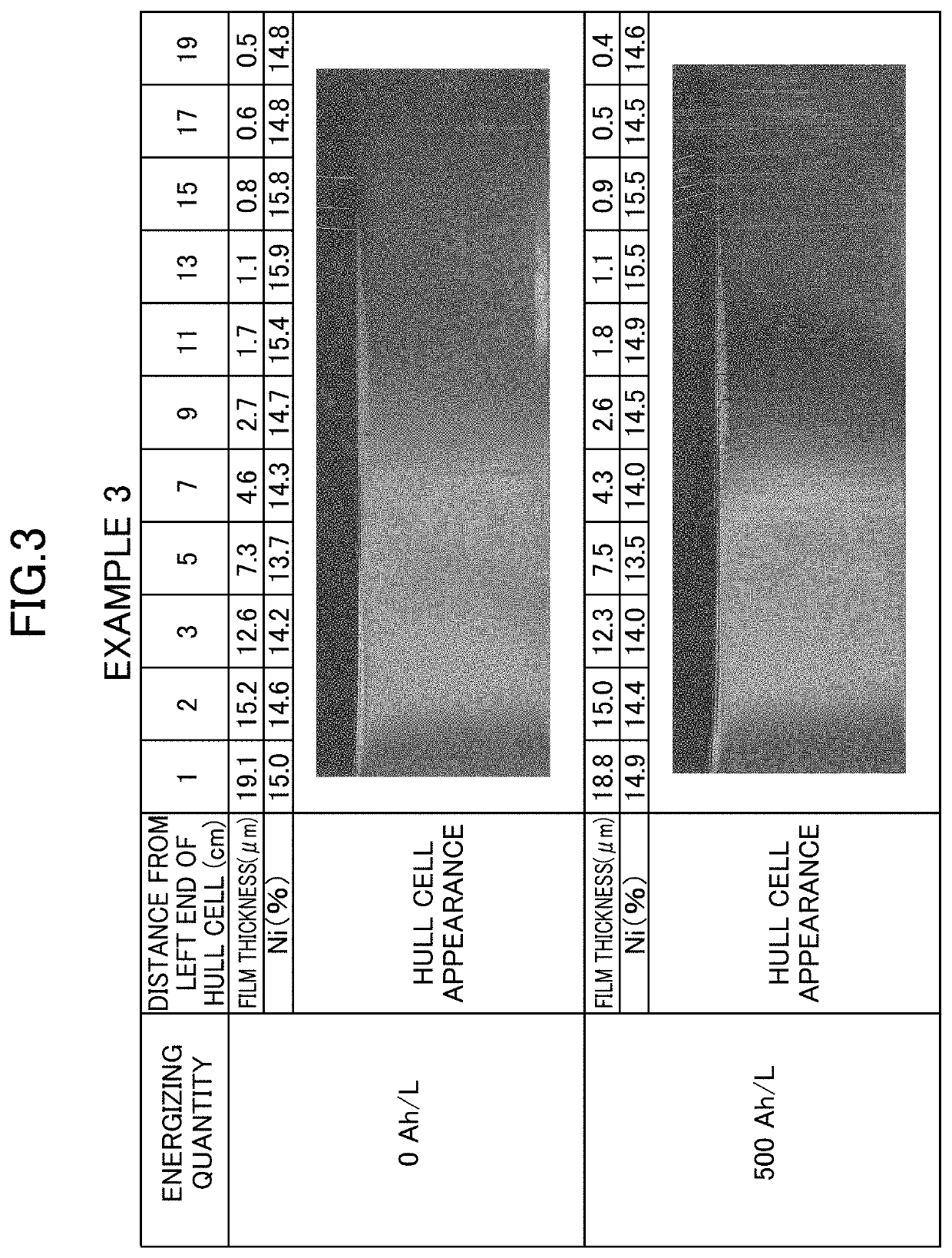

example 3

[0097]An anode plate (surface roughness Ra: 4 μm, 64×64×2 mm) coated with tantalum oxide in a thickness of 0.5 to 0.8 μm on Ni was used and an alkaline zinc nickel alloy plating bath shown below was used (500 mL) to carry out zinc nickel alloy plating with energizing of 500 Ah / L. The pore diameter in the coating film was 0.1 to and the drag-out of the plating bath was set to 2 mL / Ah. The cathode current density was 2 A / dm2, the anode current density was 4.9 A / dm2, and the plating bath temperature was 25° C. The plating bath was cooled to maintain 25° C. An iron plate was used as the cathode. Note that the iron plate of the cathode was replaced for each 16 Ah / L during the energizing. The zinc ion concentration of the plating bath was kept constant by immersion and dissolution of the metal zinc. The nickel ion concentration of the plating bath was kept constant by replenishing a nickel replenishment agent IZ-250YNi (manufactured by Dipsol). The caustic soda concentration of the platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ra | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com