Fan frame structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

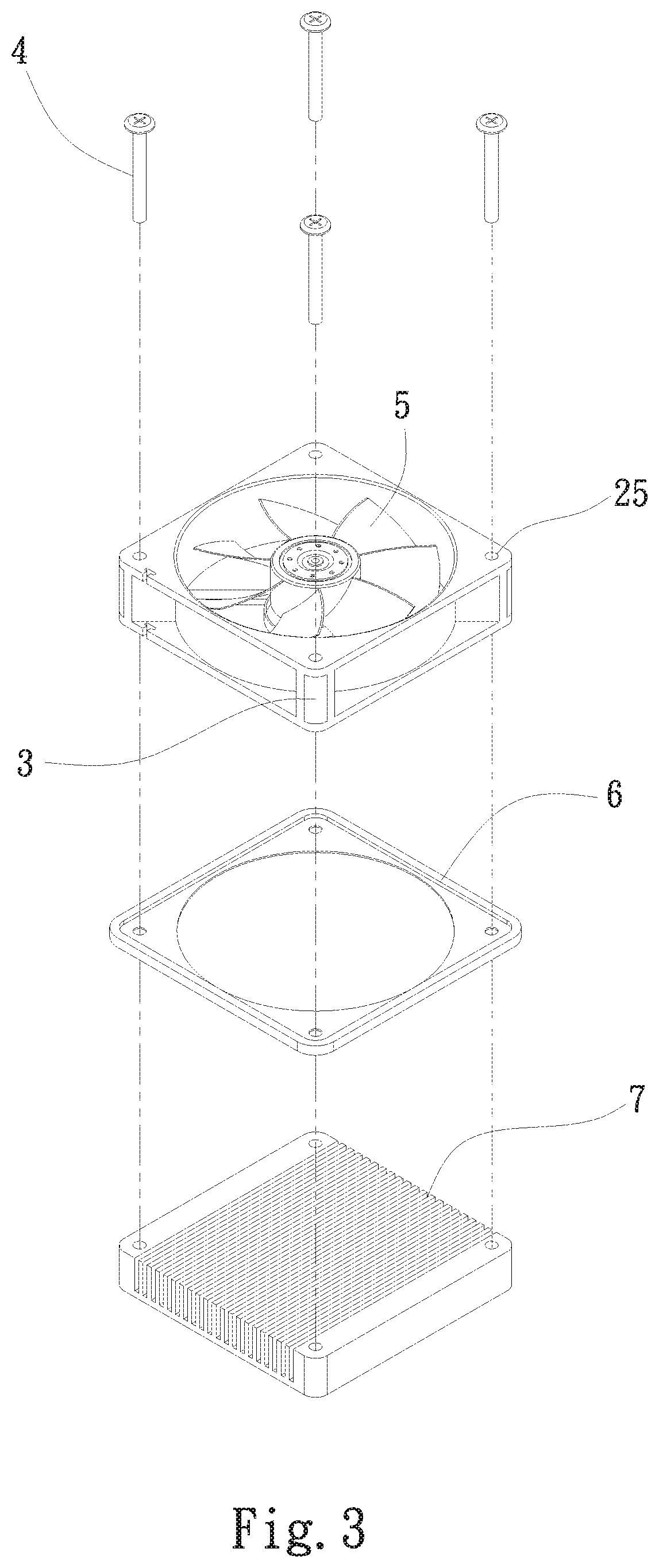

[0021]Please refer to FIGS. 2 to 4. FIG. 2 is a perspective view of a first embodiment of the frame body of the present invention. FIG. 3 is a perspective exploded view of the first embodiment of the fan frame structure of the present invention. FIG. 4 is a perspective assembled view of the first embodiment of the fan frame structure of the present invention. The fan frame structure of the present invention has a frame body 2. The frame body 2 has a base seat 22 and a circumferential wall 24. A bearing cup 23 upward extends from a center of the base seat 22. A fan impeller 5 is correspondingly pivotally disposed on the bearing cup 23. In this embodiment, the frame body 2 is, but not limited to, a rectangular frame body for illustration purposes. In practice, the frame body 2 can be alternatively a circular frame body 2. The frame body 2 further has a first side 20 and a second side. At least one locking hole 25 is formed on each of four corners of the first side 20. The locking hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com