Manipulator, system and process of operating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

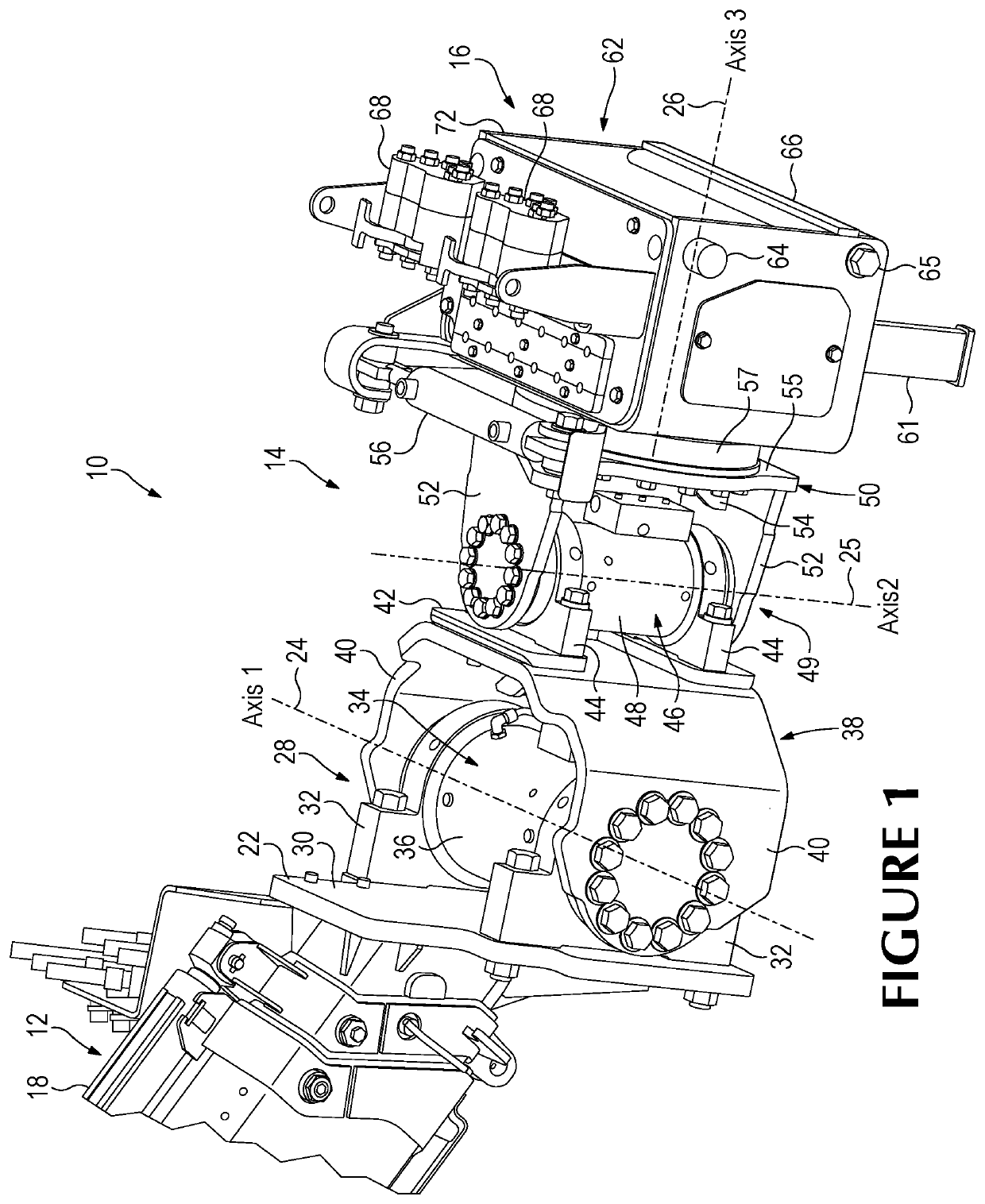

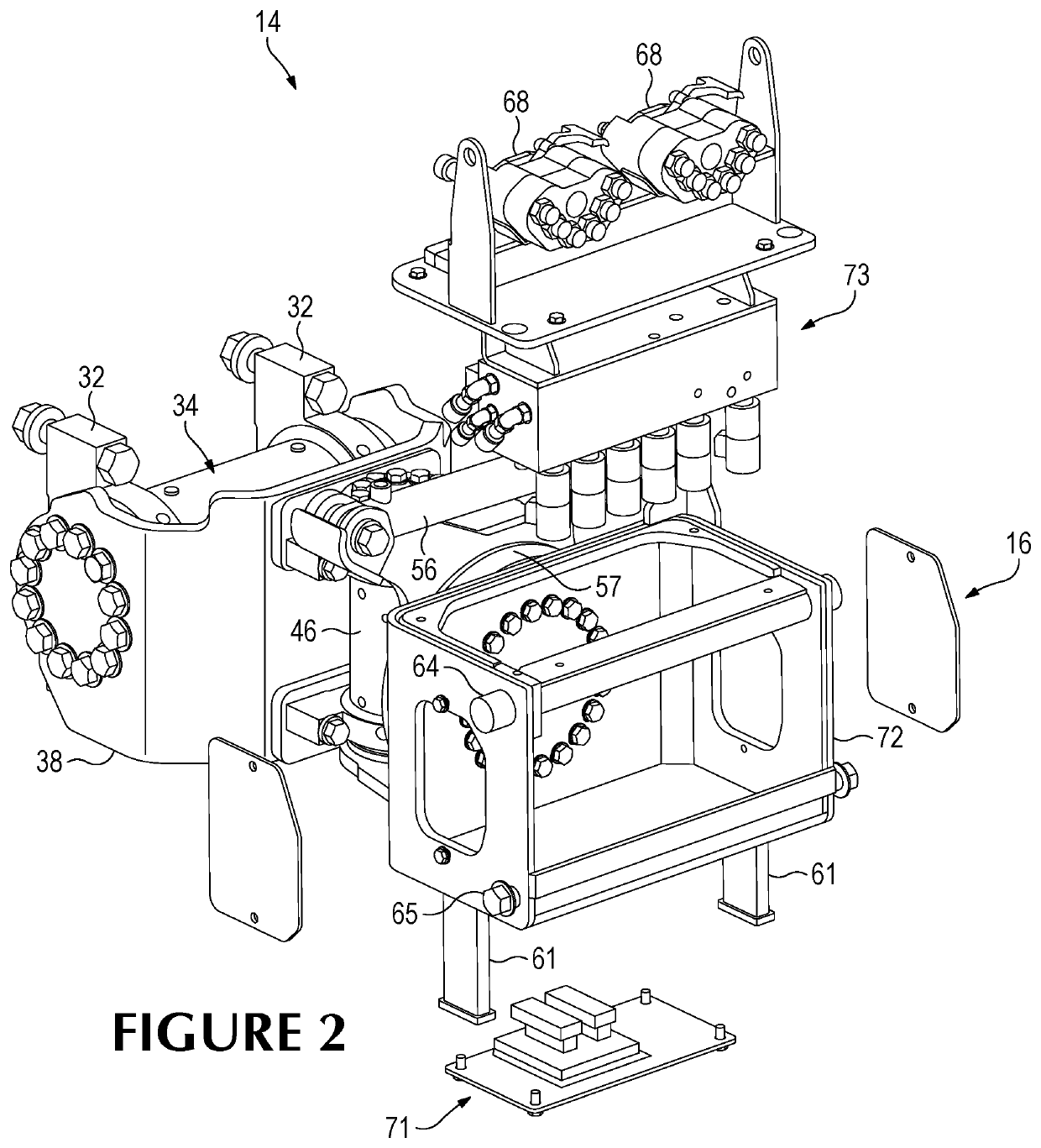

[0029]The present invention pertains to a manipulator for movably supporting one or more tools for conducting operations. A manipulator in accordance with the present invention can improve processes that are difficult, hazardous and / or time-consuming. The manipulator can, e.g., be used to assess conditions and / or perform critical operations.

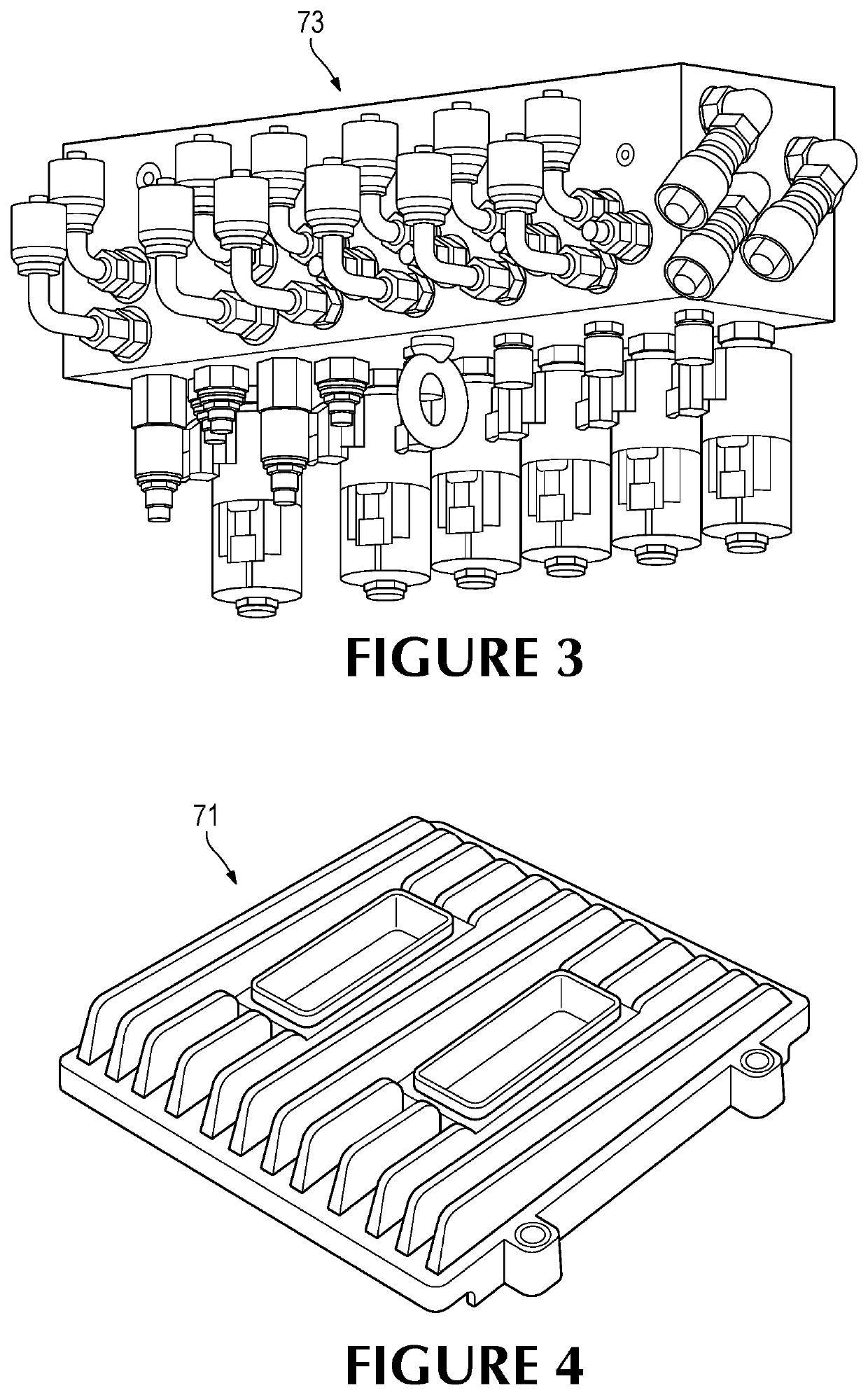

[0030]In one embodiment, the manipulator is fluid driven, preferably hydraulic to be robust in varied environmental conditions, though other drives are possible for certain operations and / or conditions. A hydraulically-driven manipulator is less susceptible (e.g., as compared to electric drives) to failure in in-field operations where it may be subject to varied environmental conditions such as heat, cold, precipitation, dirt, fines, dust, smoke, corrosive materials, etc. A hydraulic drive is also able to provide substantial power by compact means (e.g., as compared to electric drives), which is useful for certain applications; one such example i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com