Device for detecting balance of hub valve hole

a hub valve and detection device technology, applied in measurement devices, structural/machine measurement, instruments, etc., can solve the problems of low manual operation efficiency, reduce the repeated operation of operators, and accurately identify the hub type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 2

hole detection device

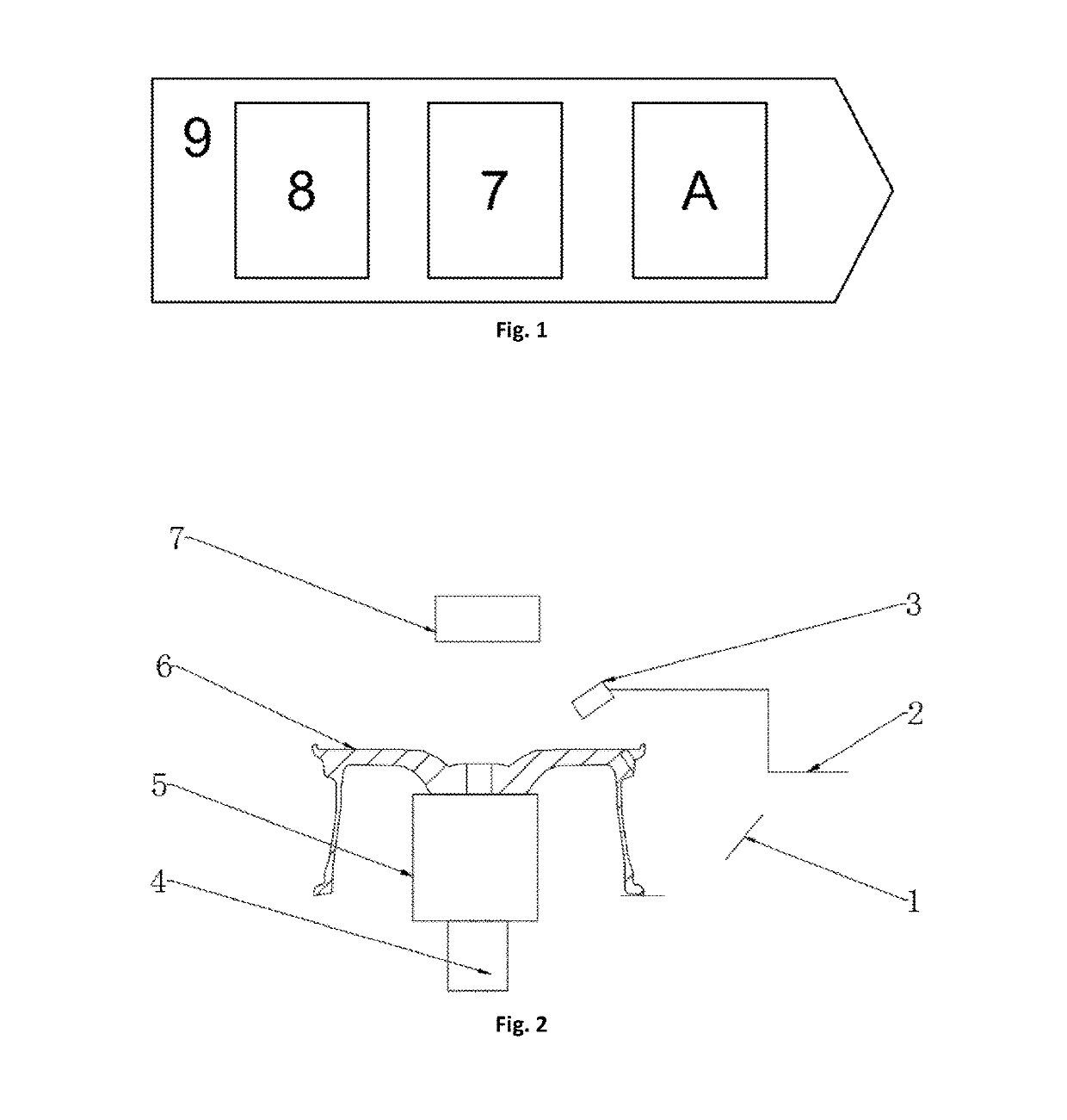

[0027]As described in Embodiment 1, after different types of hubs 6 are preliminarily weighed by the electronic belt scale 8 and identified, the weight of the hub 6 is compared with the database of an industrial personal computer for rough analysis, then the hub 6 runs to the station of the industrial camera 7, and the unique type of the hub is identified.

[0028]For example, the weight of the hub 6 is measured to give a weight fluctuation range of ±100 g; the similarity of the measured photos of the hub 6 is matched by 95%; the criterion is that the wheel type having the similarity of more than 95% is subjected to weighing data comparison, and the type of the hub 6 is distinguished through the weight; and unique determination is performed on the hub 6 having the picture similarity of less than 95%, so that accurate identification on the type of the hub 6 can be ensured.

[0029]After the type of the hub 6 is determined, the weight value of the valve hole weight is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com