Preparation method of shuttle spokes

a technology of spokes and spokes, which is applied in the field of preparation of spokes, can solve the problems of reducing the efficiency of flat spokes in reducing wind resistance compared to arch spokes, affecting the quality of finished products, so as to reduce the exterior resistance of spokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]With the following description of embodiment of the present invention, skilled technicians can easily learn other strengths and functions of the present invention through the disclosed information provided in the instruction.

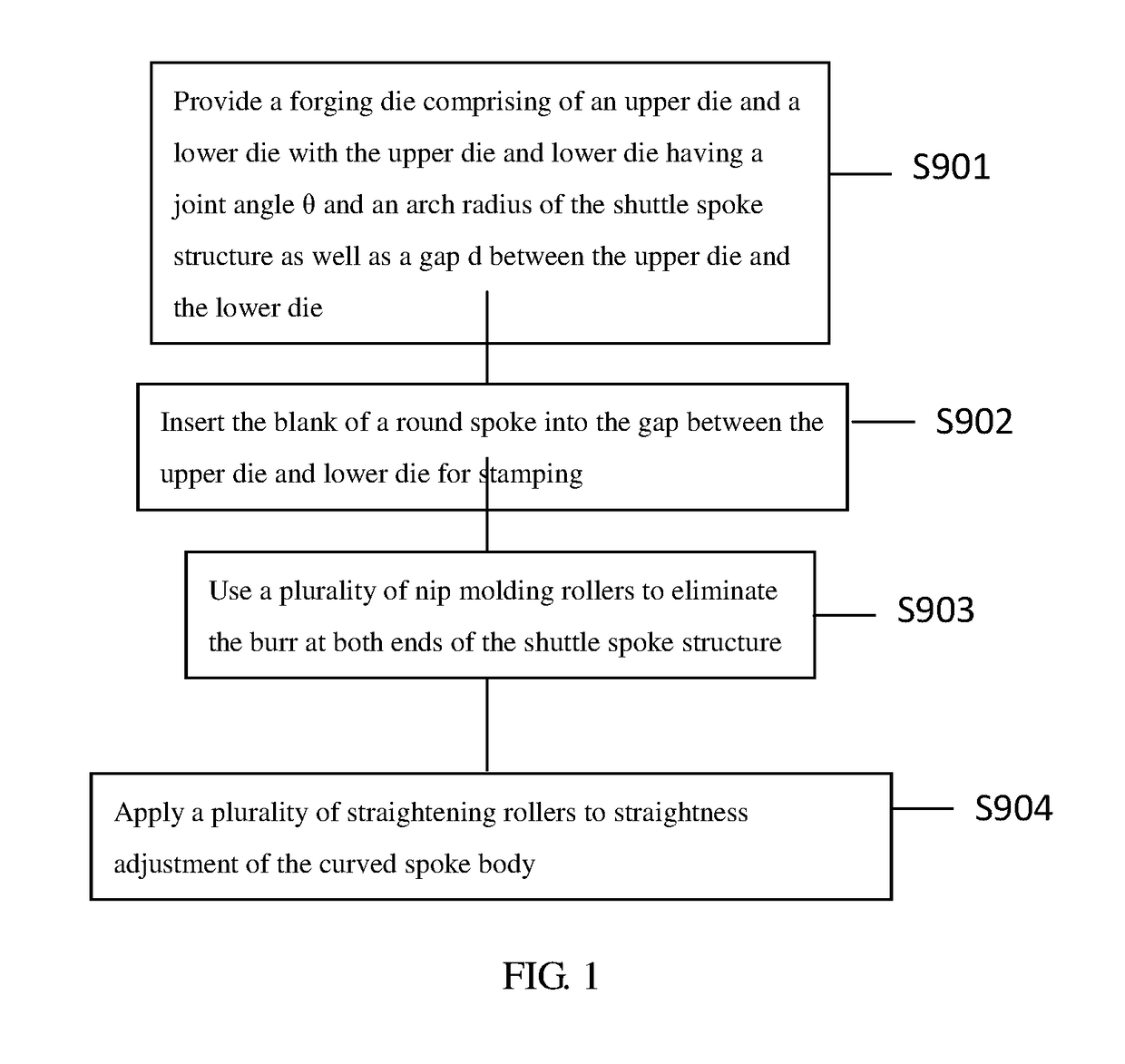

[0030]Referring to FIG. 1, a flow chart of the preparation method of shuttle shape spokes, it indicates the preparation method of the shuttle shape spokes described in the present invention, including the steps as follows:

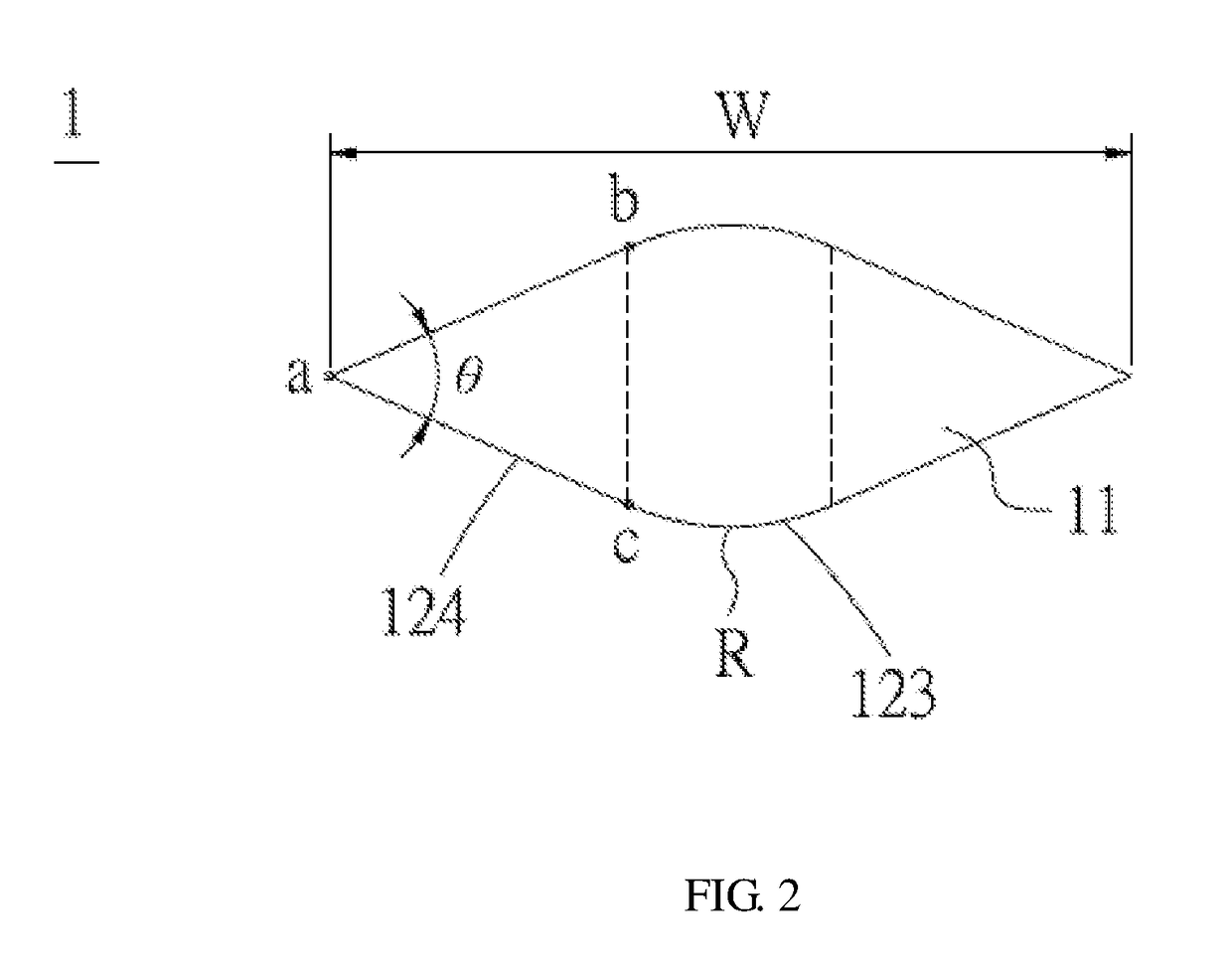

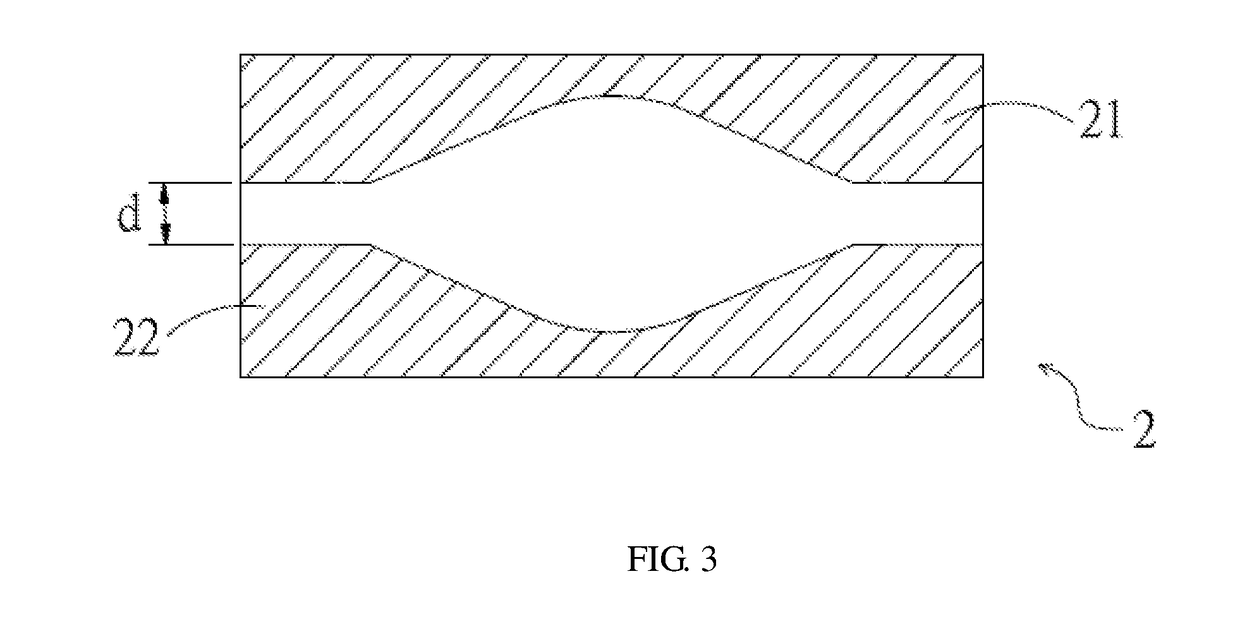

[0031]Step 901: Provide a forging die 2 comprising of an upper die 21 and a lower die 22 with the upper die 21 and lower die 22 having a joint angle θ and an arch radius 123 of the shuttle shape spoke 1 structure as well as a gap d between the upper die 21 and the lower die 22;

[0032]Step 902: Insert the blank 3 of a round spoke into the gap between the upper die 21 and lower die 22 for stamping;

[0033]Step 903: Use a plurality of nip molding rollers 4 to eliminate the burr 15 at both ends of the shuttle shape spoke 1 structure; and

[0034]St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cone angle | aaaaa | aaaaa |

| coning angle | aaaaa | aaaaa |

| joint angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com