Method for optimized color control in a printing machine

a printing machine and color control technology, applied in the field of color control in the printing operation, can solve the problems of high labor intensity, high cost, and high accumulation of individual sampling points, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

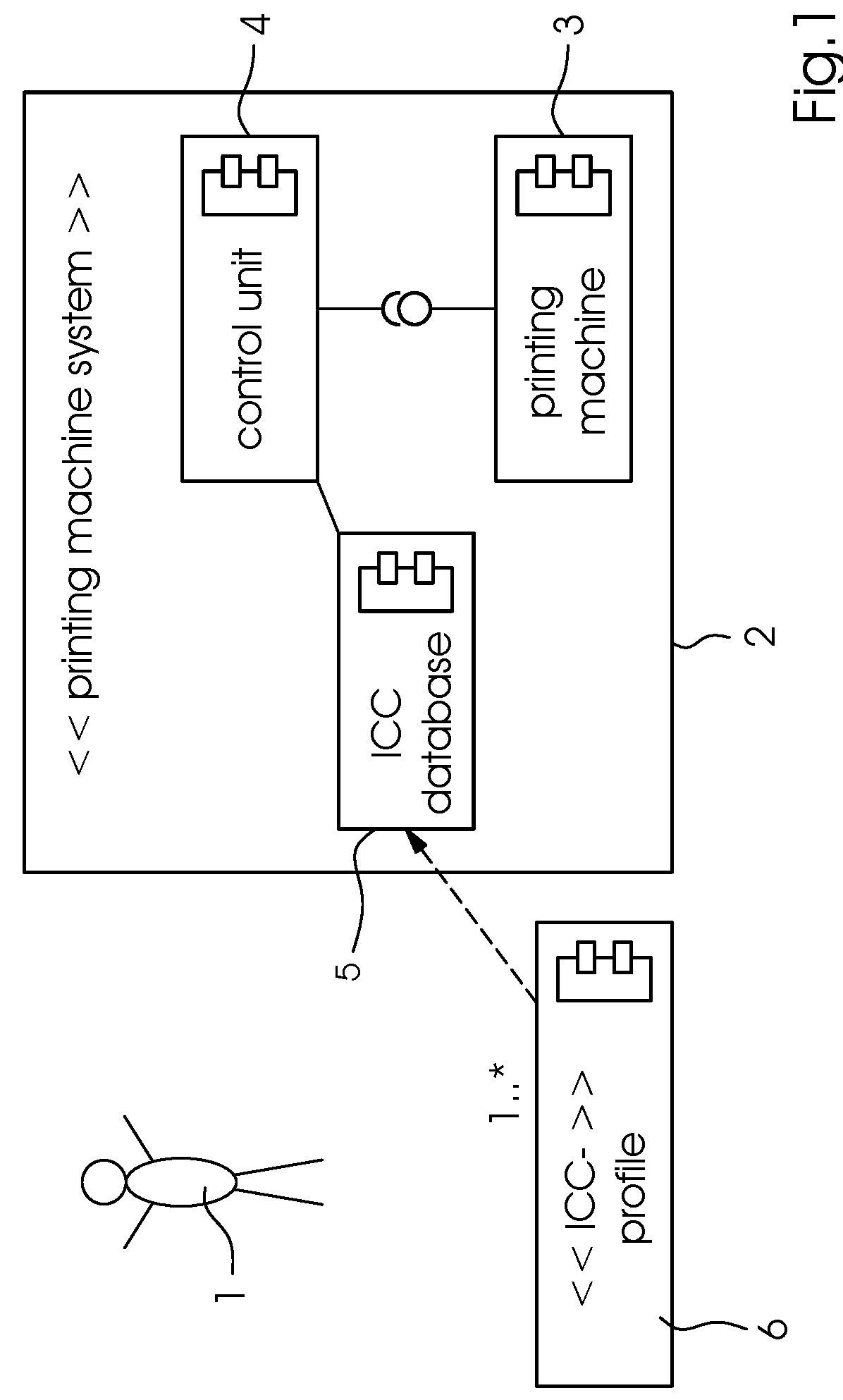

[0042]Referring now in detail to the figures of the drawings, in which identical reference symbols identify mutually corresponding elements, and first, particularly, to FIG. 1 thereof, there is seen a block diagram of a printing machine system 2, on which the method of the invention is preferably implemented. In addition to an inkjet printing machine 3 itself, the system is formed of an inkjet printing machine control unit 4 on which ICC profiles 6 to be corrected are saved in a database 5. Apart from the control unit 4 of the printing machine 3, any other computer that allows an operator 1 to access the color management of the printing operation may be used.

[0043]The preferred embodiment of the method of the invention has a number of requirements:

[0044]It is to take up much less memory space than the current ICC profiles 6. It is to be able to reduce information where it is redundant in a perception-adapted way. Moreover, it is to be able to reduce information where it is irrelevan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com