Coating machine and coating method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

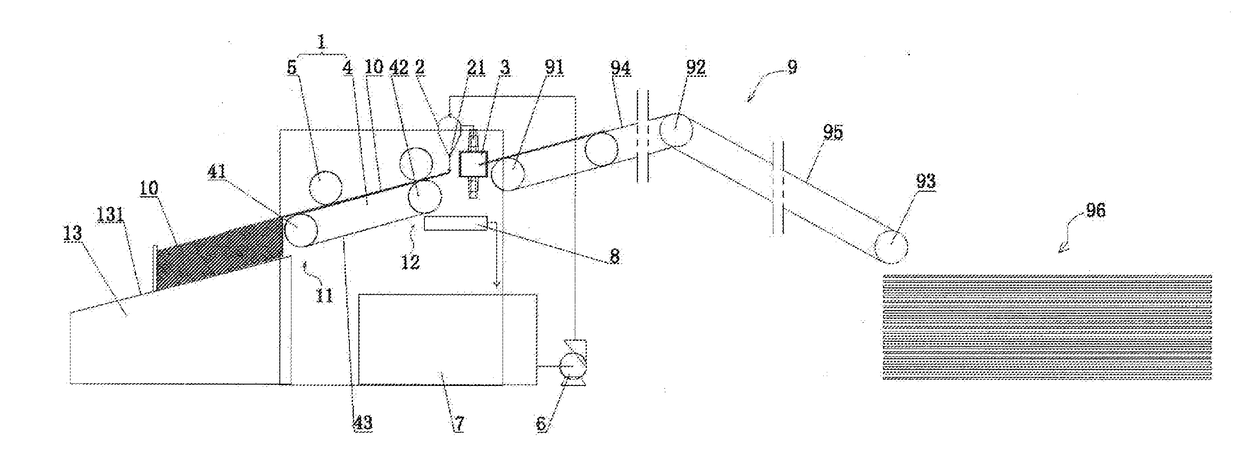

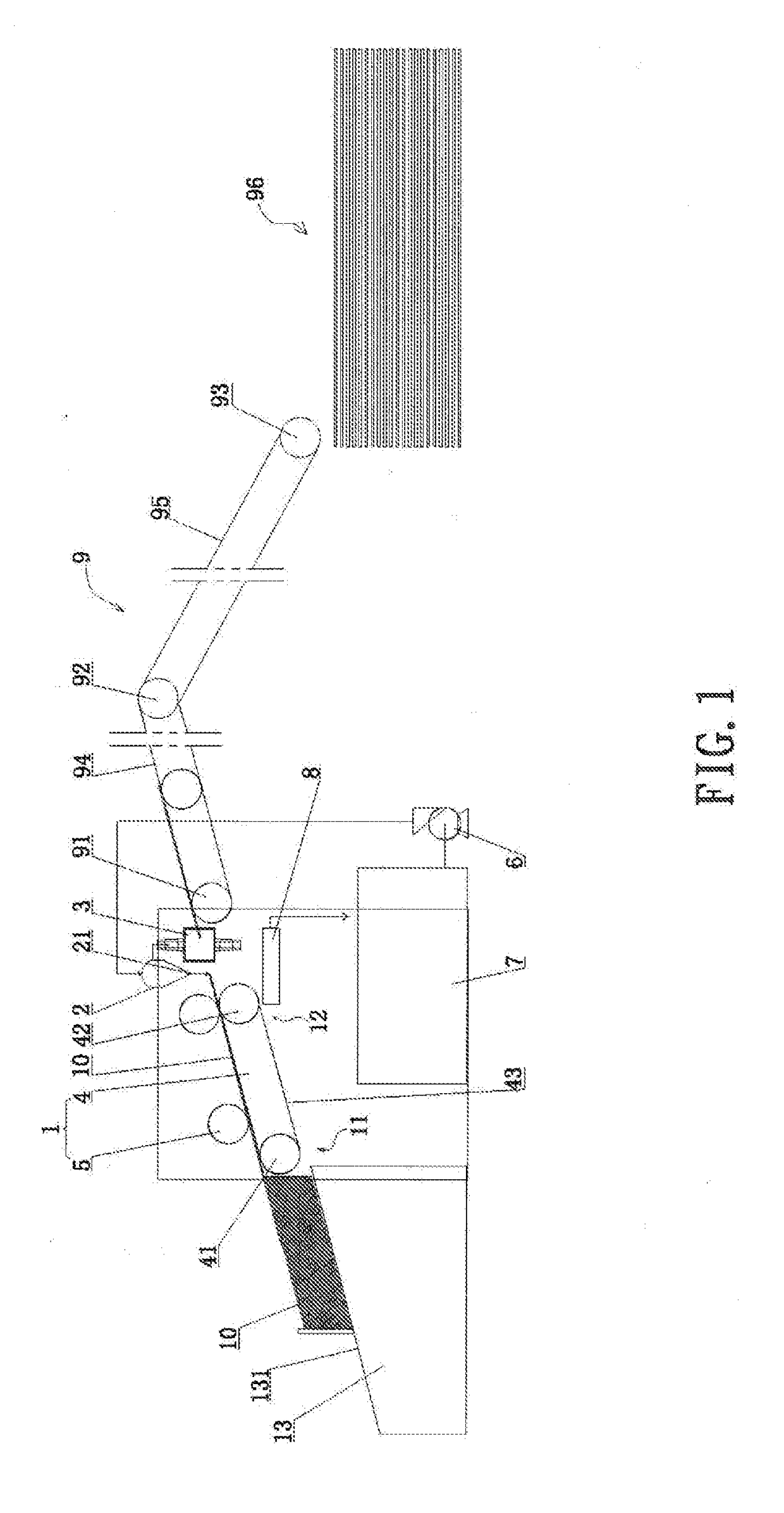

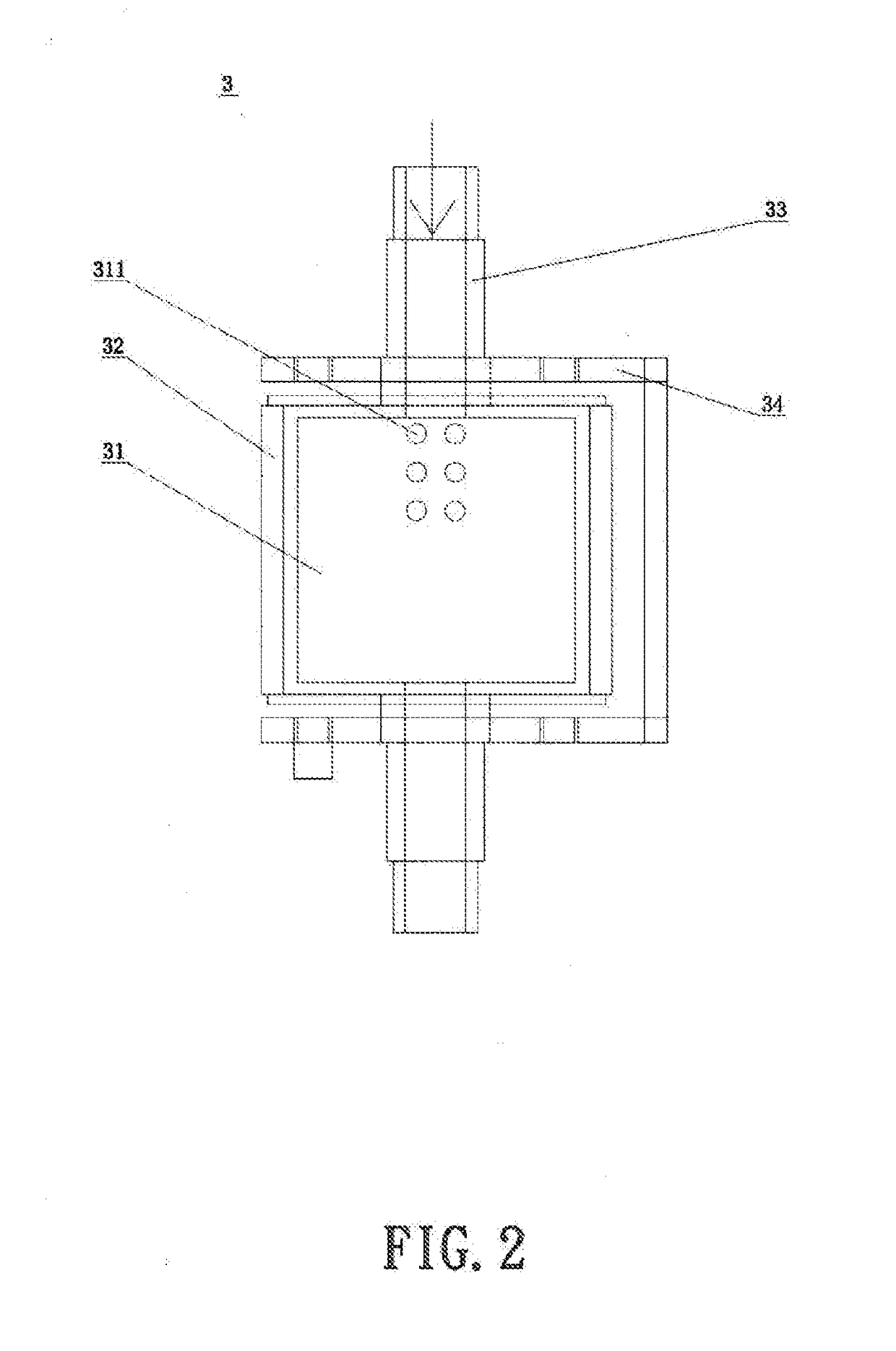

[0035]As shown in FIG. 1, the present invention provides a coating machine that includes a cardboard conveying mechanism 1 and a wax dispenser 2. The cardboard conveying mechanism 1 has a front end 11 and a back end 12, wherein the front end 11 is lower than the back end 12. The wax dispenser 2 is provided above the back end 12, and a wax dispensing roller 3 is provided on each of two lateral sides of the wax dispenser 2.

[0036]More specifically, the cardboard conveying mechanism 1 includes a conveyor body 4 and a plurality of pressure rollers 5. The conveyor body 4 has a front-end conveying wheel 41, a back-end conveying wheel 42, and a conveyor belt 43 looped around the front-end conveying wheel 41 and the back-end conveying wheel 42. Cardboard 10 can be placed on the conveyor belt 43 in order to be coated. The cardboard 10 may be a single- or multi-ply composite cardboard having a thickness ranging from 0.3 mm to 9 mm; the present invention has no limitation in this regard. The pr...

embodiment 2

[0045]With continued reference to FIG. 1 and FIG. 2, the present invention further provides the coating method of a coating machine. The structures, working principle, and advantageous effects of the coating machine in embodiment 2 are identical to those of the coating machine in embodiment 1 and hence will be not be described repeatedly. The coating method of the coating machine includes the following steps:

[0046]a) Place the cardboard 10 on the cardboard conveying mechanism 1, with the wax dispenser 2 in vertical alignment with the forward edge of the cardboard 10;

[0047]b) Turn on the wax dispenser 2 and the cardboard conveying mechanism 1 so that the wax dispenser 2 dispenses wax to the forward edge and the upper surface of the cardboard 10; and

[0048]c) Wax the two lateral edges of the cardboard 10 with the wax dispensing rollers 3 on the two lateral sides of the wax dispenser 2 respectively while the cardboard 10 is moved from the front end 11 of the cardboard conveying mechanis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com