Adjustable Hydraulic Coupling For Drilling Tools And Related Methods

a hydraulic coupling and drilling tool technology, applied in the direction of drilling pipes, drilling casings, borehole/well accessories, etc., can solve the problems of limited use of mwd tools of the types described, difficulty in all applications, and limited depth of em systems, so as to reduce the cost of installation and removal, and reduce the occurrence and severity of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

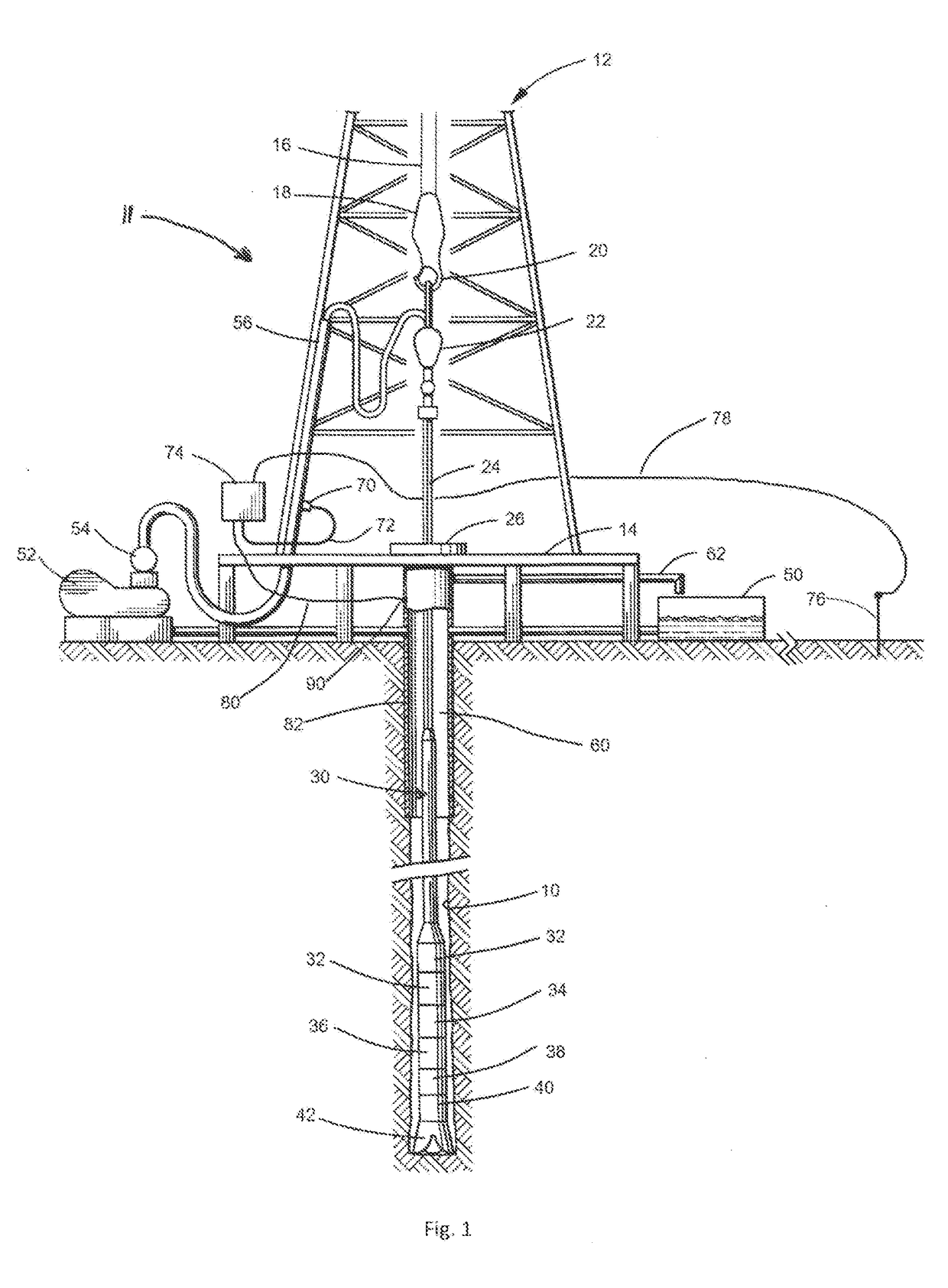

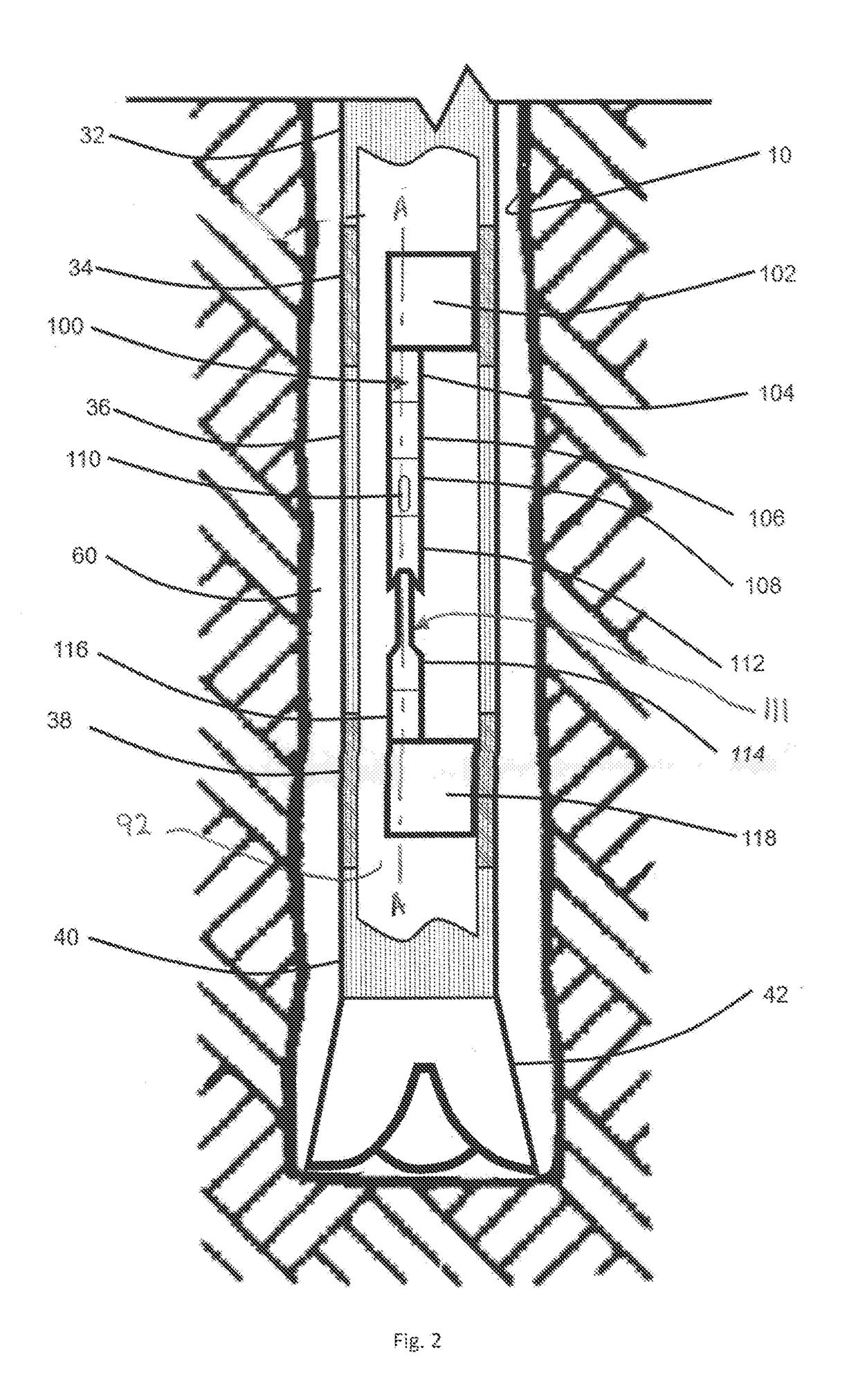

[0043]In an embodiment of the invention, information of use to the driller is measured at the bottom of a bore hole relatively close to the drilling bit and this information is transmitted to the surface using pressure pulses in the fluid circulation loop. This information, or other information, may also be transmitted using a secondary telemetry device which could be a second mud pulser transmitter, an EM telemetry device or an acoustic telemetry device. Some of the data thus gathered to transmit may be acquired from sensors or systems that are mounted to the drill string near the top or bottom of the MWD Tool.

[0044]The command to initiate the transmission of data is sent by stopping fluid circulation and allowing the drill string to remain still for a minimum period of time. Upon detection of this command, the downhole tool measures at least one downhole condition, which is usually an analog signal. The signal is processed by the downhole tool and readied for transmission to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com