Insulated container for and method of cooling a heated tooling component

a technology of insulated containers and tooling components, which is applied in the direction of containers preventing decay, forming tools, foundry moulding apparatus, etc., can solve the problems of distortion and cracking of tooling components, affecting the cooling effect of the component, so as to achieve the effect of controlling the air flow rate through the chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

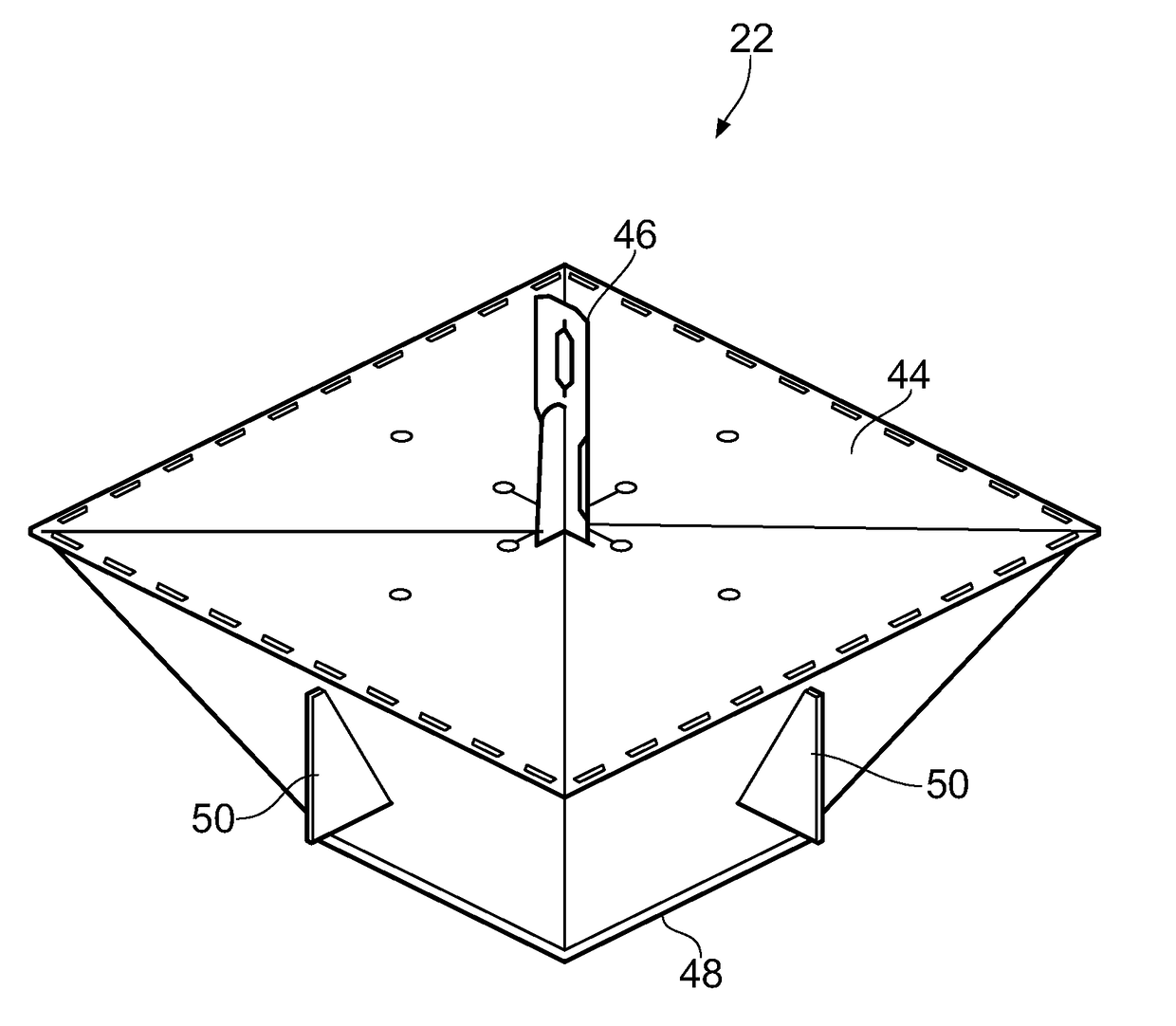

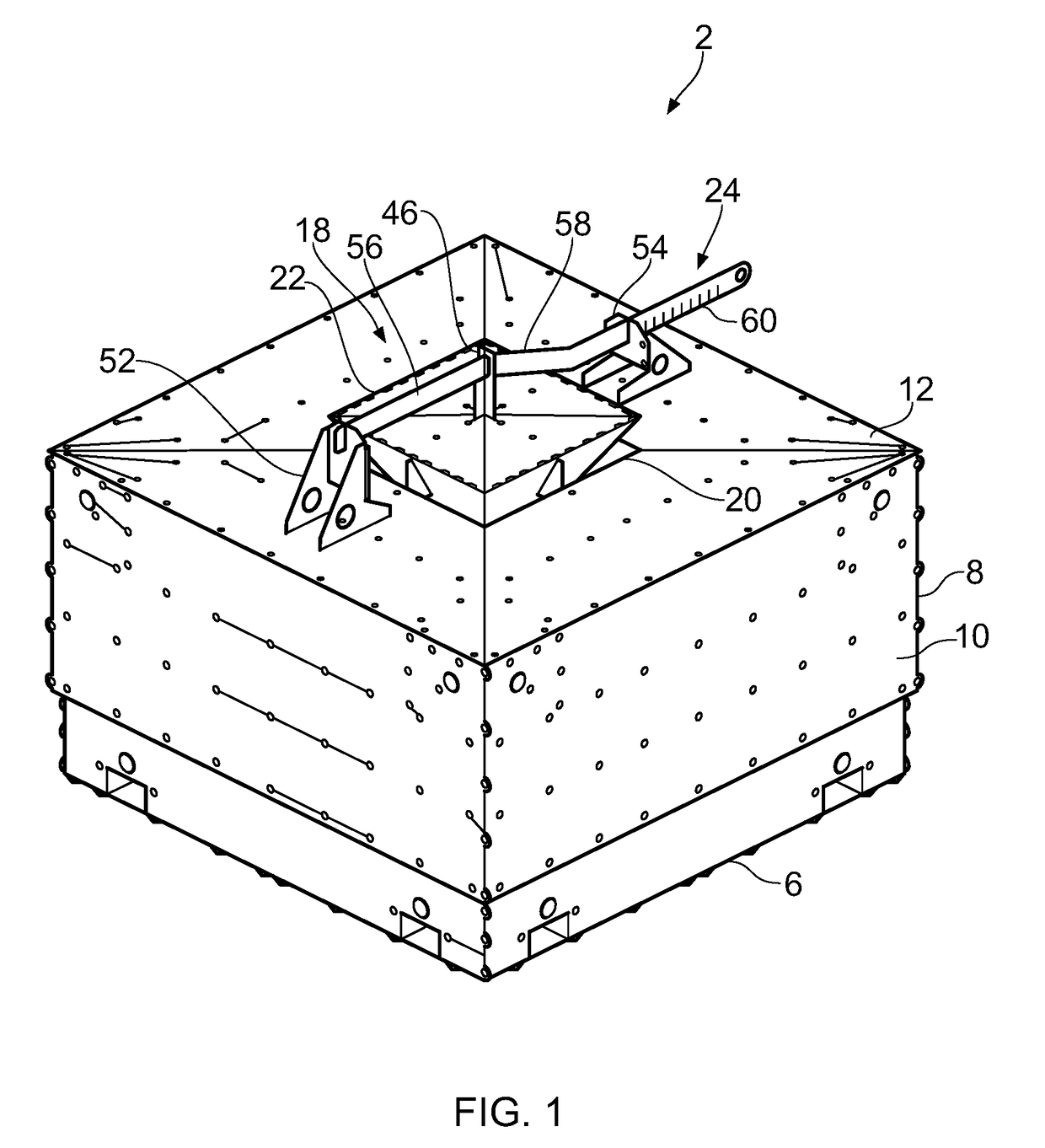

[0037]FIG. 1 shows an insulated container 2 for cooling a heated tooling component 4 (see FIGS. 5A and 5B). The insulated container 2 generally comprises a thermally insulated base 6 and a thermally insulated cover 8, which together form a housing. The thermally insulated cover 8 comprises four thermally insulated side walls 10 and a thermally insulated upper wall 12 connected to the side walls 10. A lower surface 14 (see FIGS. 5A and 5B) of the cover 8 is detachably coupled to an upper surface 16 (see FIG. 2) of the base 6. Consequently, the cover 8 is detachably coupled to the base 6. A vent 18 passes through the upper wall 12. The vent 18 generally comprises an opening 20 passing through the upper wall 12, a valve member 22 and a linear actuator 24.

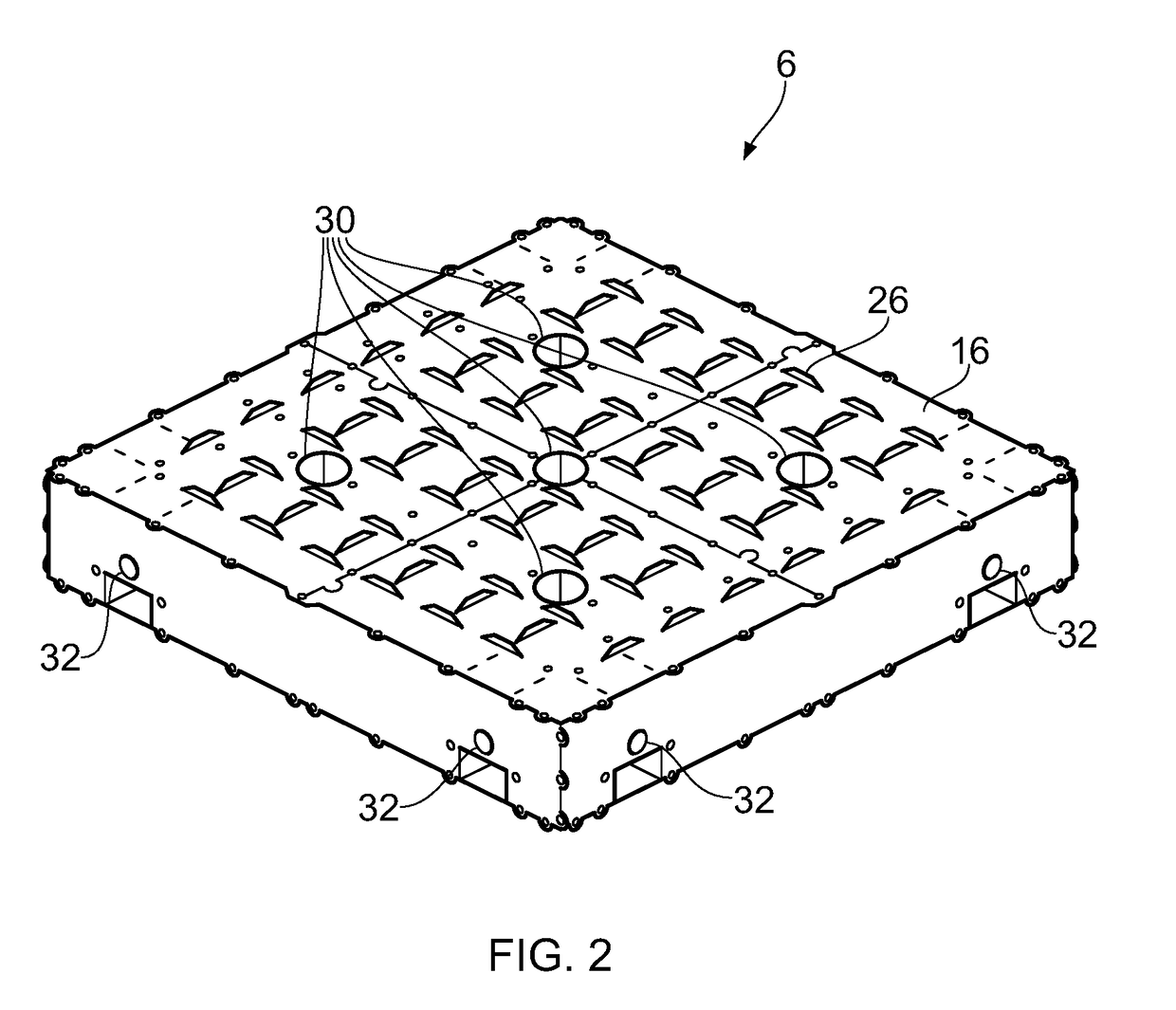

[0038]FIG. 2 shows the base 6 in isolation. The base 6 comprises a metal exterior and an insulating core. The base 6 is substantially cuboid in shape, has a substantially square profile when viewed from above and is substantially plana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| air flow rate | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flow area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com