System and Articles of Interchangeably Connectable Pre-Wired Segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

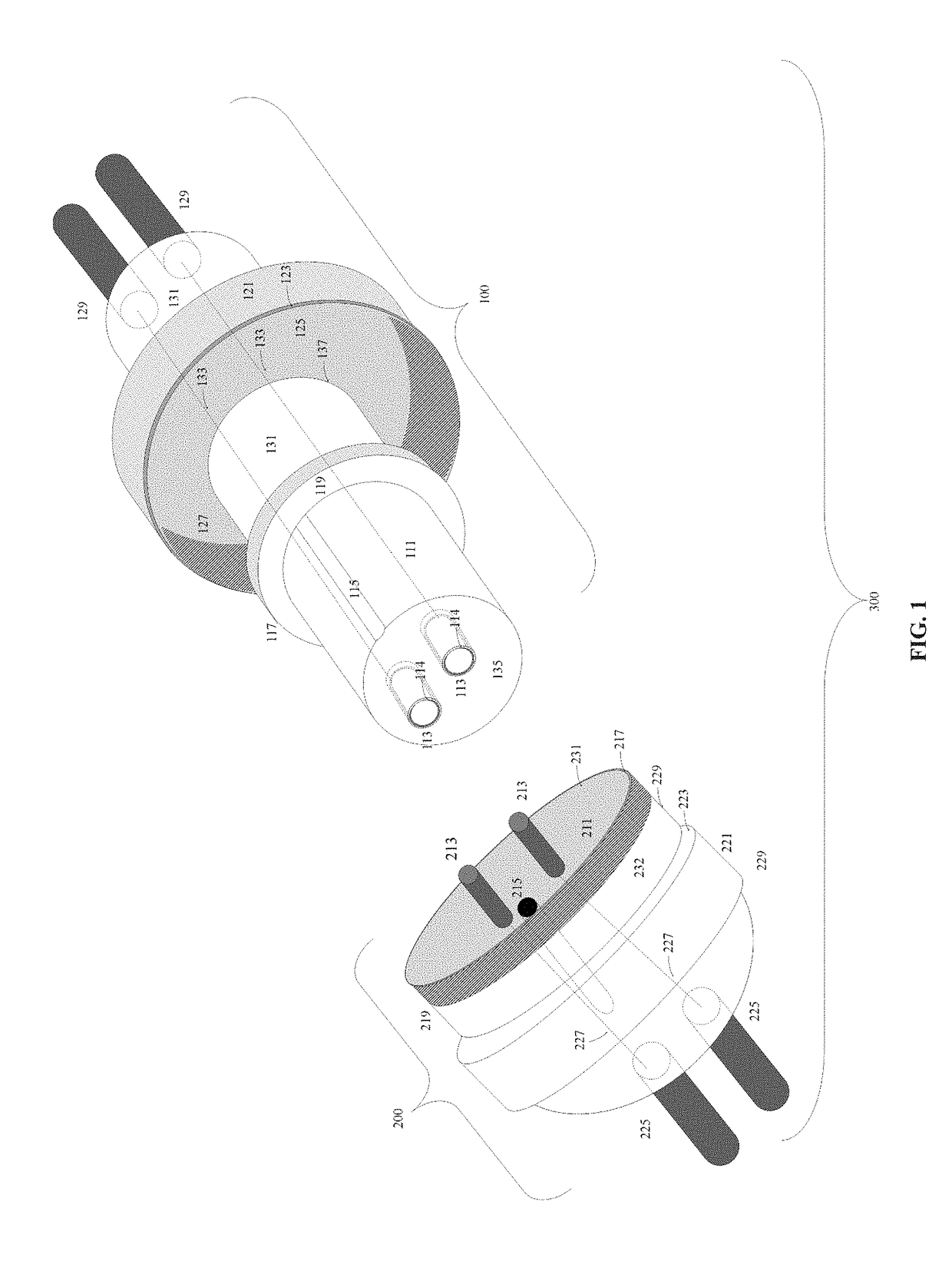

[0083]The present invention discloses a system of interchangeably connectible elements which are prewired and have mating electro-mechanical connectors. FIG. 1 shows one possible embodiment of the mating electro-mechanical connectors, namely, an ungrounded (i.e., two pin) Coupling Assembly 300.

[0084]The Coupling Assembly 300 is comprised of a mating Female Coupling Assembly 100 and a Male Coupling Assembly 200.

[0085]The Female Coupling Assembly 100 comprises a Coupling Shaft 131 attached to a Telescoping Coupling Shaft 111. In the preferred embodiment, the Telescoping Coupling Shaft 111 is formed out of an insulating material. A protruding Female Flange 117 defines the boundary between the Coupling Shaft 131 and the Telescoping Coupling Shaft 111. The Female Flange 117 has a Female Flange Surface 119 such that the plane of the Female Flange Surface 119 is perpendicular to the plane defined by the Telescoping Coupling Shaft 111. A Coupling Groove 115 extends along the cylindrical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com