Heating appliance structure

a technology for heating appliances and structures, applied in water heaters, fluid heaters, light and heating equipment, etc., can solve the problems of common drawbacks of heating appliances of the prior, shortcoming, etc., and achieve the effect of resolving the shortcomings of wasting energy resources and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

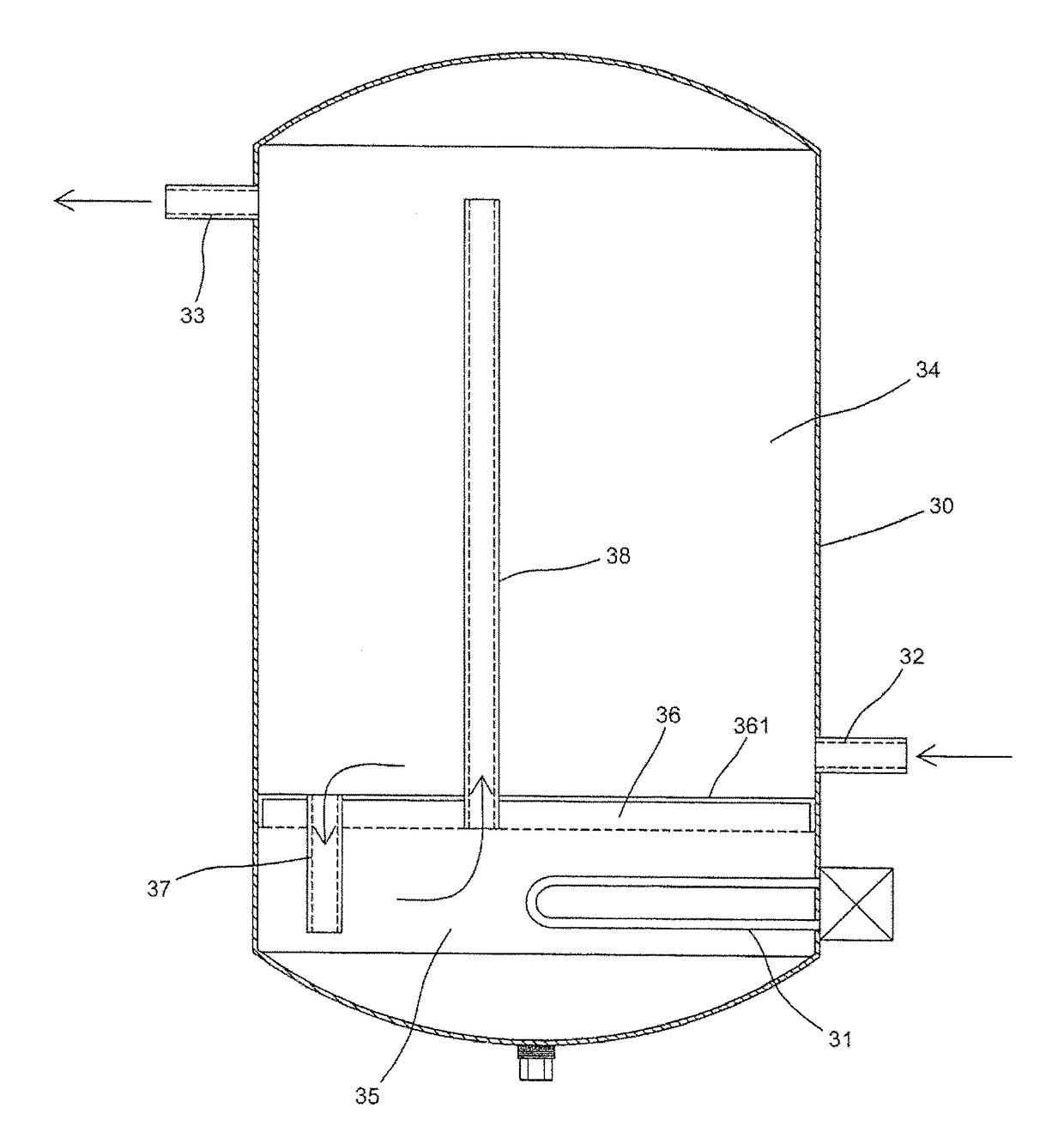

[0024]Referring to FIG. 3, which depicts the first embodiment of a heating appliance structure of the present invention comprising a cylinder 30, a heating pipe 31, a water inlet pipe 32, a water outlet pipe 33, a water storage area 34, and a heating area 35. The cylinder 30 is able to store water, and the interior of the cylinder 30 is partitioned into the heating area 35 and the water storage area 34. The heating pipe 31 extends into the heating area 35 of the cylinder 30, the water inlet pipe 32 channels water into the water storage area 34 within the cylinder 30 from the exterior thereof, and the water outlet pipe 33 channels out heated water from the cylinder 30 to the exterior of the cylinder 30 using the water outlet pipe 33. The heating area 35 is provided with the heating pipe 31 for conducting heat thereto, and an upper portion of the heating area 35 is provided with a heat flow conduit 38, which extends to the water outlet pipe 33 for channeling out heated water to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com