Agricultural harvesting unit and method of harvesting using the unit

a harvesting unit and agricultural technology, applied in the field of agricultural harvesting, can solve the problems of user inconvenience, waste of valuable harvesting time, and inability to directly observe the front region of the harvesting system, and achieve the effect of facilitating the rearward progress of severed crops and facilitating severance of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

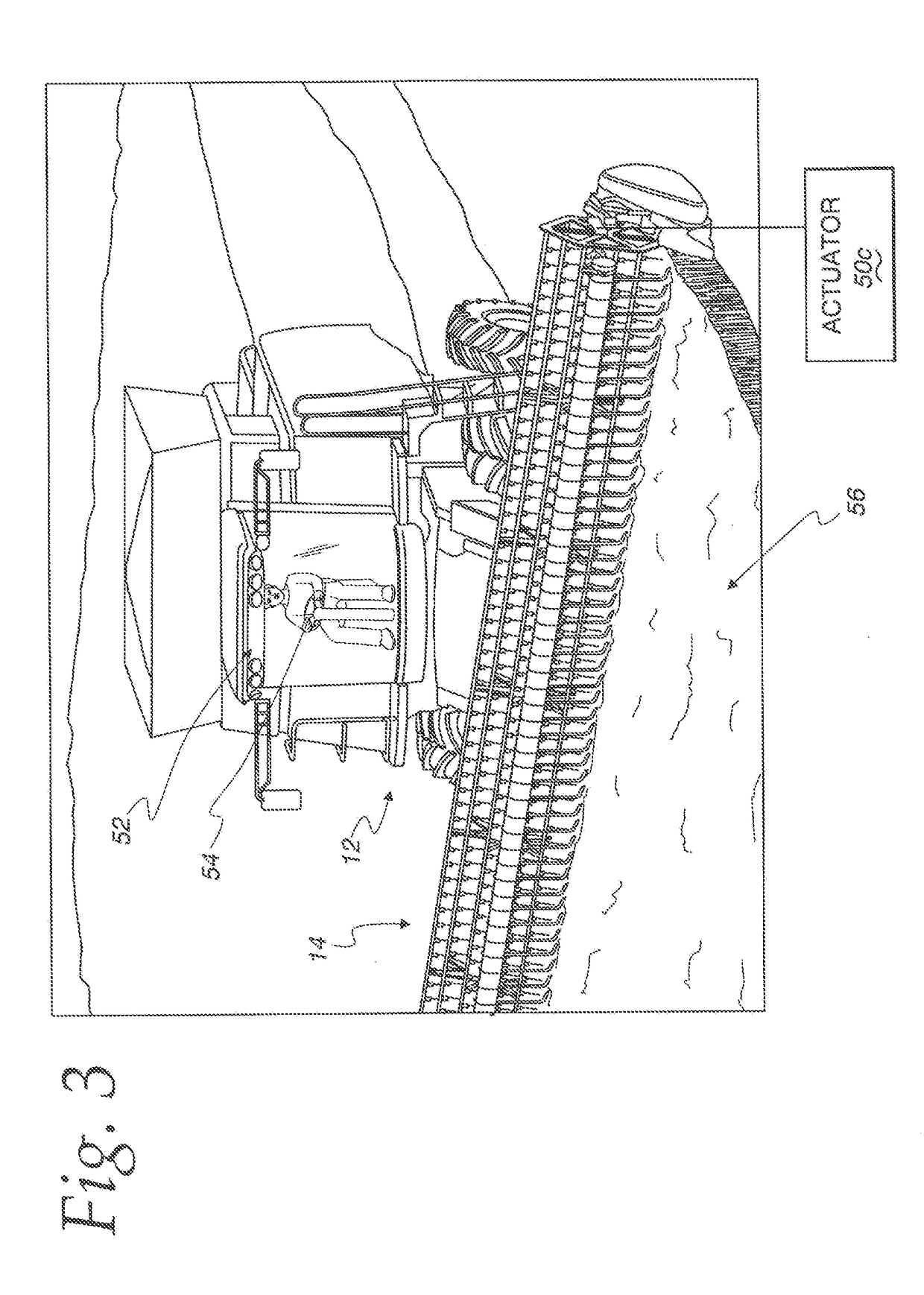

[0043]A harvesting unit, according to the invention, is shown schematically at 10 in FIG. 1. The harvesting unit 10 is made up of a combine 12, configured to be advanced over underlying terrain, and a harvesting apparatus at 14, configured to be advanced by the combine 12 over an area in which crop is grown. The harvesting apparatus 14 is commonly referred to as a “head” that may be releasably joined to the combine 12 through cooperating connectors 16, 18, respectively on the combine 12 and harvesting apparatus 14.

[0044]The harvesting apparatus 14 has a frame 20 that supports operating components for the harvesting apparatus 14. The frame 20 has laterally spaced sides, a front, and a rear.

[0045]A harvesting assembly 22 on the frame 20 is configured to process crop over a width between spaced sides of the frame 20 as it is advanced. The harvesting assembly 22 may be configured to: a) sever crop; and / or b) process pre-severed crop, as by controlled delivery to the combine 12.

[0046]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com