Plunger-type dispensing valve for the rapid deposition of adhesive to road pavement surfaces for enabling the fixation of pavement markers to road pavement surfaces

a technology of adhesive and dispensing valve, which is applied in the direction of valve operating means/releasing devices, functional valve types, valves, etc., can solve the problem that the valve needs to dispense adhesive materials extremely quickly, and achieve the effect of facilitating soft starts, minimizing the likelihood of formation, and minimizing the pressure prevailing at the valve member or shutoff blad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

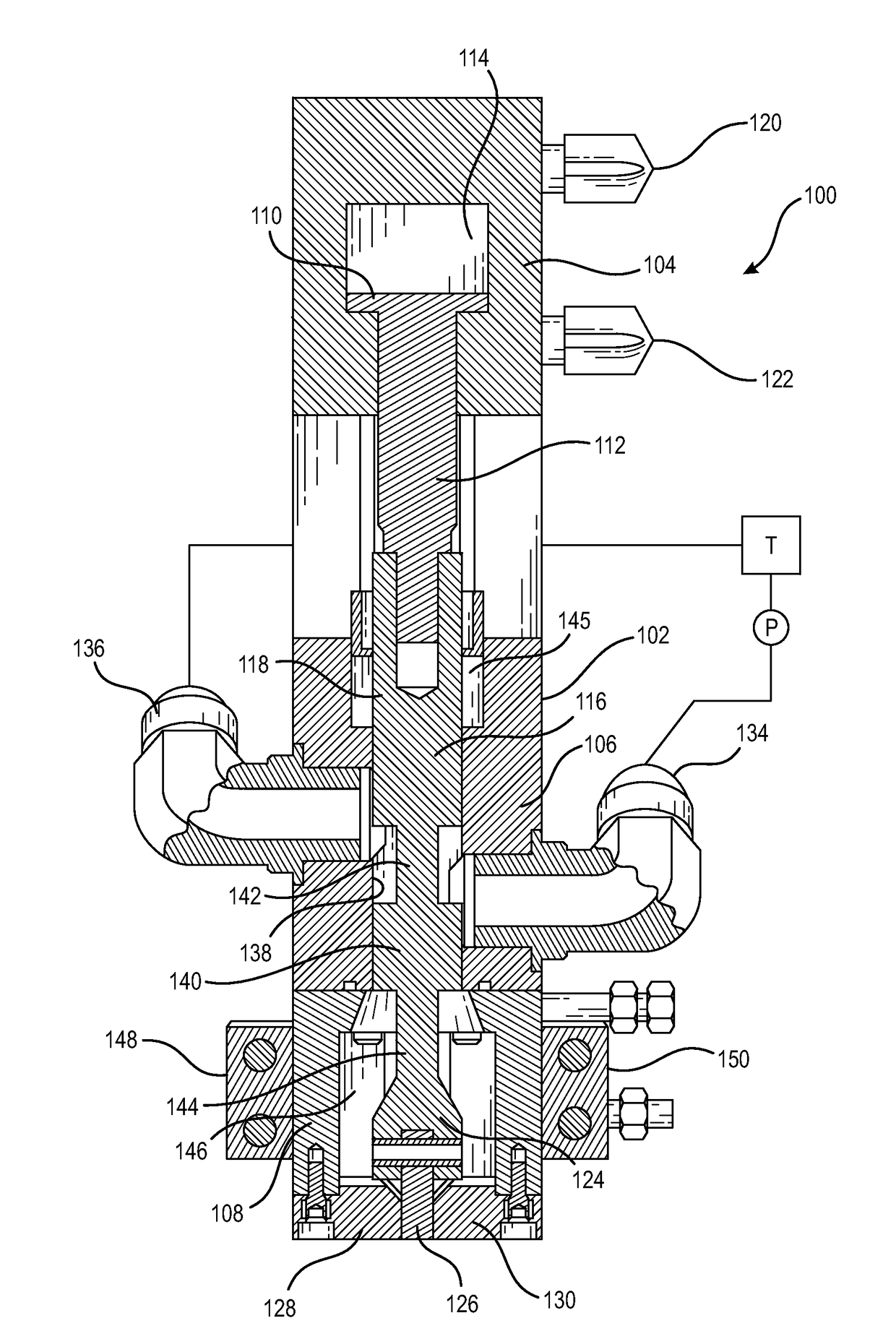

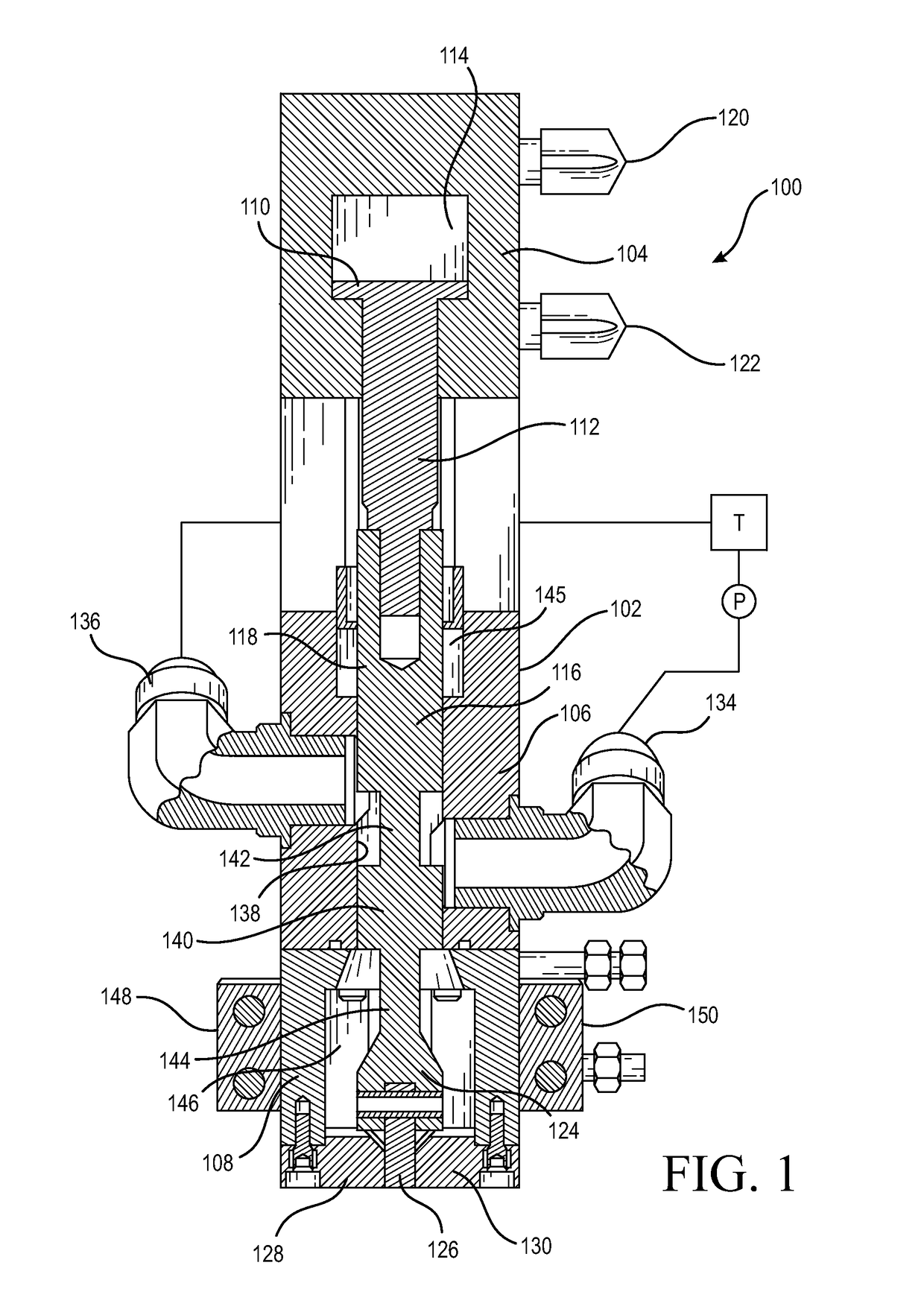

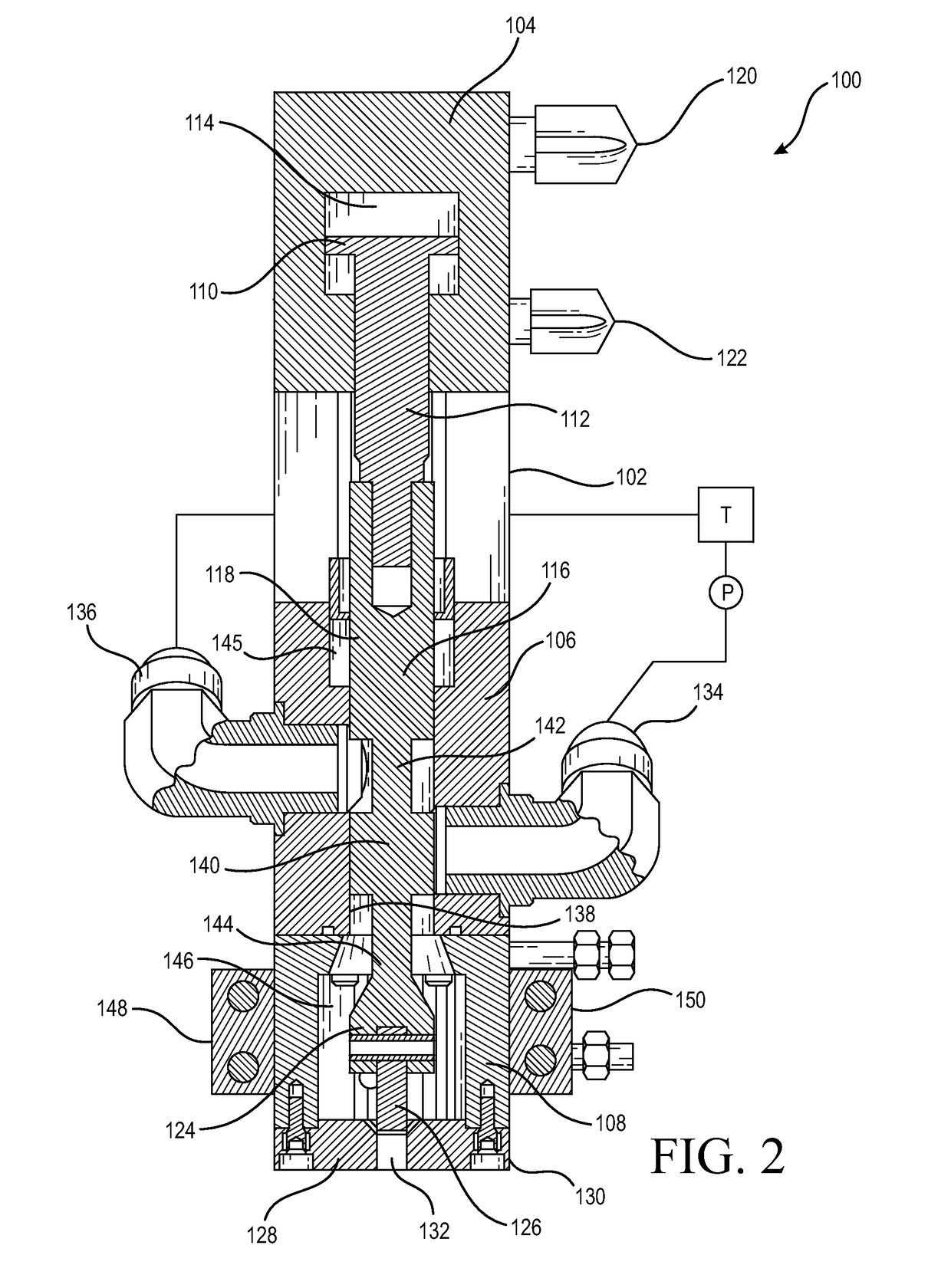

[0017]Referring now to the drawings, and more particularly to FIG. 1 thereof, the new and improved plunger-type dispensing valve is disclosed and is generally designated by the reference character 100. More particularly, it is seen that the dispensing valve 100 comprises a valve housing 102 wherein the valve housing 102 effectively comprises a first uppermost section 104, a second intermediate section 106, and a third lowermost section 108. A piston-cylinder assembly is disposed within the first uppermost section 104 of the valve housing 102 and is seen to comprise a piston which, in turn, comprises a piston head 110 and a piston rod 112, the piston head 110 being vertically movable within a cylinder portion 114 of the first uppermost section 104 of the valve housing 102. A lower end portion of the piston rod 112 is fixedly connected to a first uppermost enlarged diameter portion 116 of a valve plunger 118. The piston-cylinder assembly may be operated either pneumatically or hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com