Synthetic resin container with window, preform, and method of injection molding preform

a technology of synthetic resin and container, applied in the field of synthetic resin containers, can solve the problems of inconvenient use, contents may be poured too much to be spilled out, etc., and achieve the effect of spoiling the appearance of the window section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066]The following describes a synthetic resin container with a window made by biaxial stretch blow molding, a preform, and an injection molding method of the disclosure, with reference to examples and the drawings.

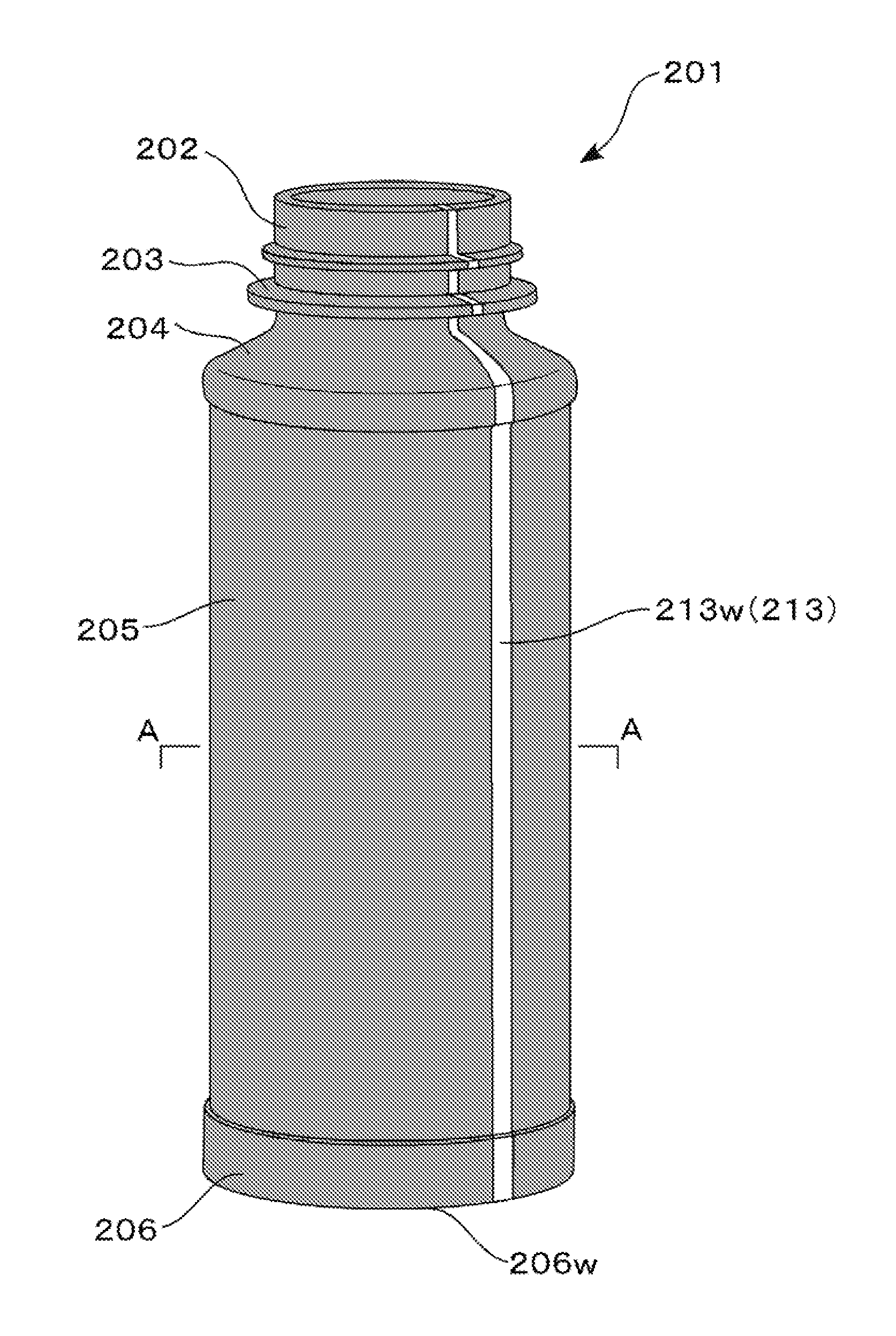

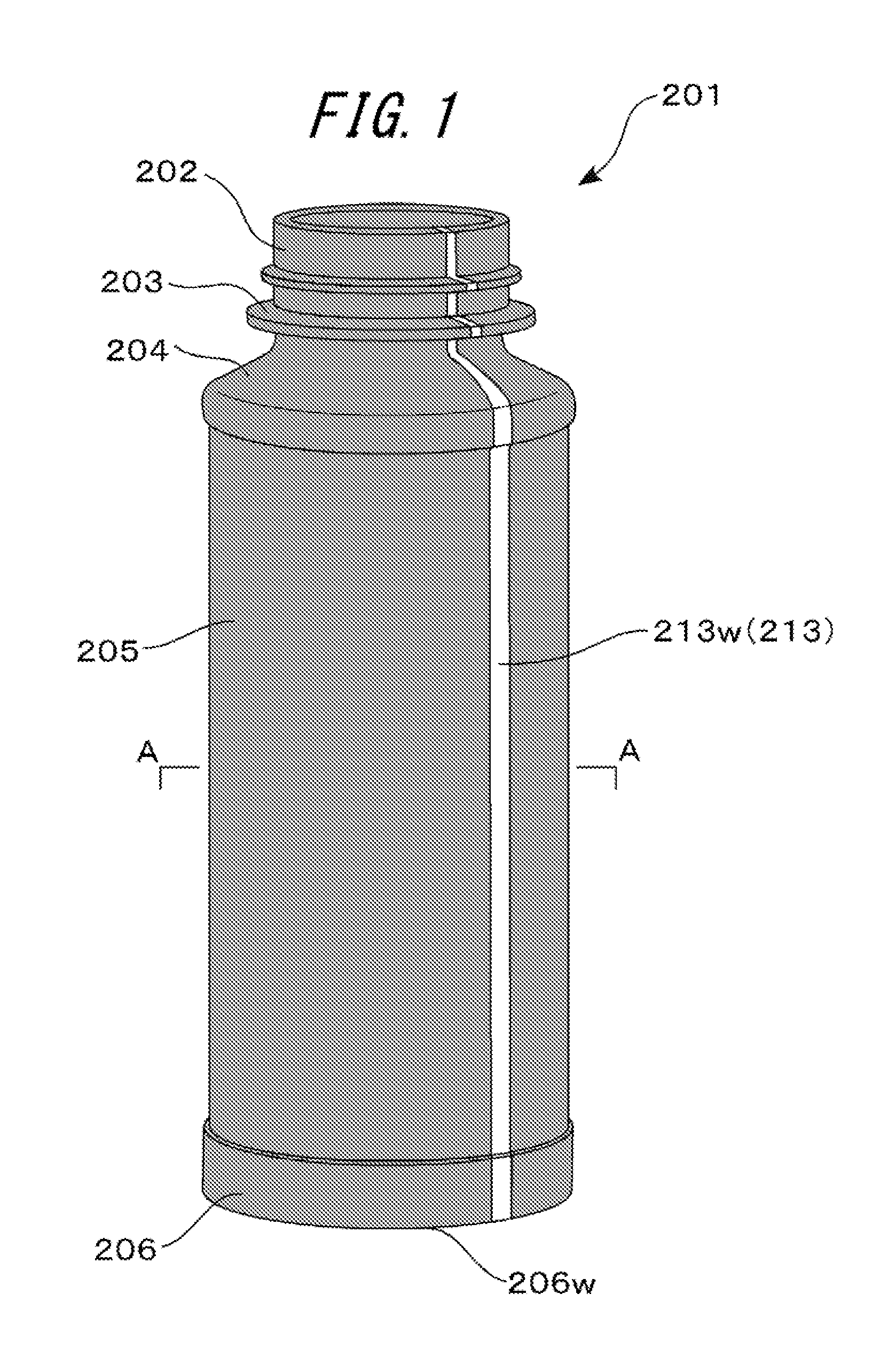

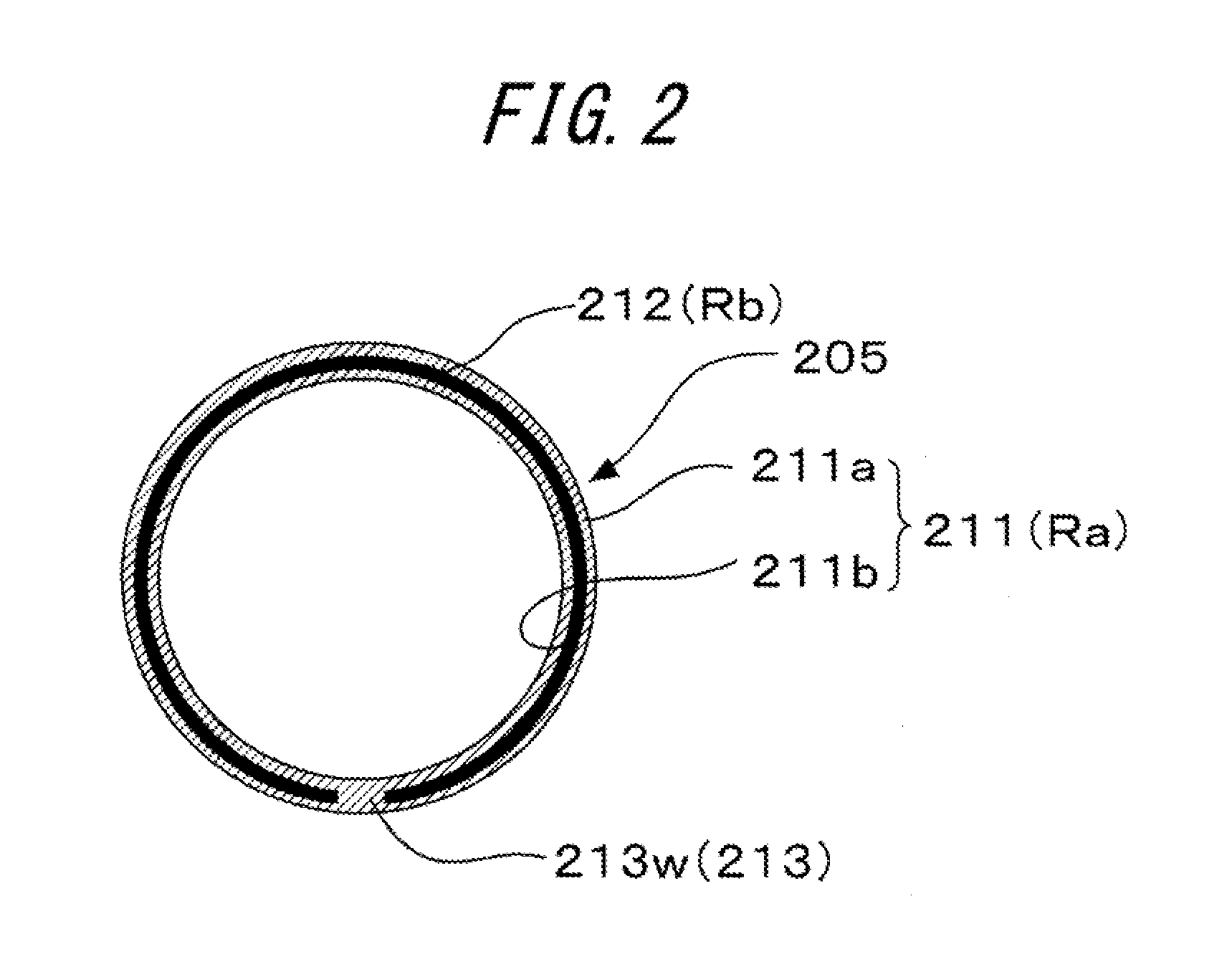

[0067]FIGS. 1 and 2 illustrate one example of a container with a window of the disclosure, where FIG. 1 is an overall perspective view and FIG. 2 is a plane cross-sectional view taken along the line A-A of FIG. 1.

[0068]This container 201 is a bottle of PET resin, which is made by subjecting a test tube-shaped preform 101, which will be described below, to biaxial stretch blow molding. The container 201 includes a mouth tube 202, a tapered-tube shoulder 204, a cylindrical body 205, and a bottom 206. The mouth tube 202 has a circumferential neck ring 203. The body 205 has a diameter of 55 mm and a total height of 190 mm.

[0069]The circumferential wall of the container 201 has a laminated structure composed of three layers. Specifically, an intermediate layer 212 is formed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com