Self-drilling expansion fastener and method of forming same

a self-drilling, expansion fastener technology, applied in the direction of metal-working feeding devices, forging/pressing/hammering apparatuses, handling devices, etc., can solve the problems of high expansion fastener manufacturing cost, troublesome above installation, and disadvantages of assembling and installation of conventional expansion fasteners, etc., to improve working efficiency and simplify the working procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The present invention will now be described with a preferred embodiment thereof and with reference to the accompanying drawings.

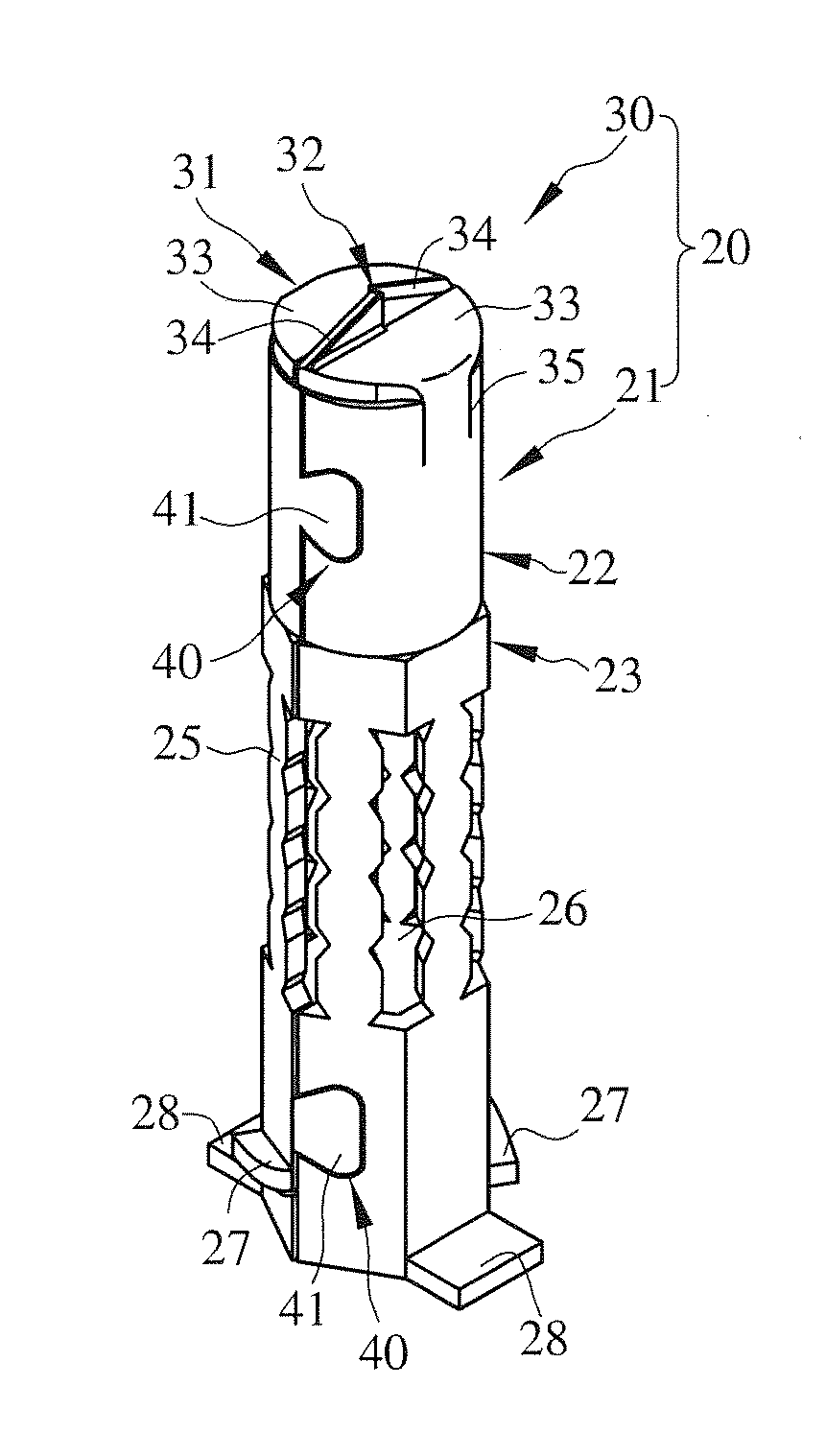

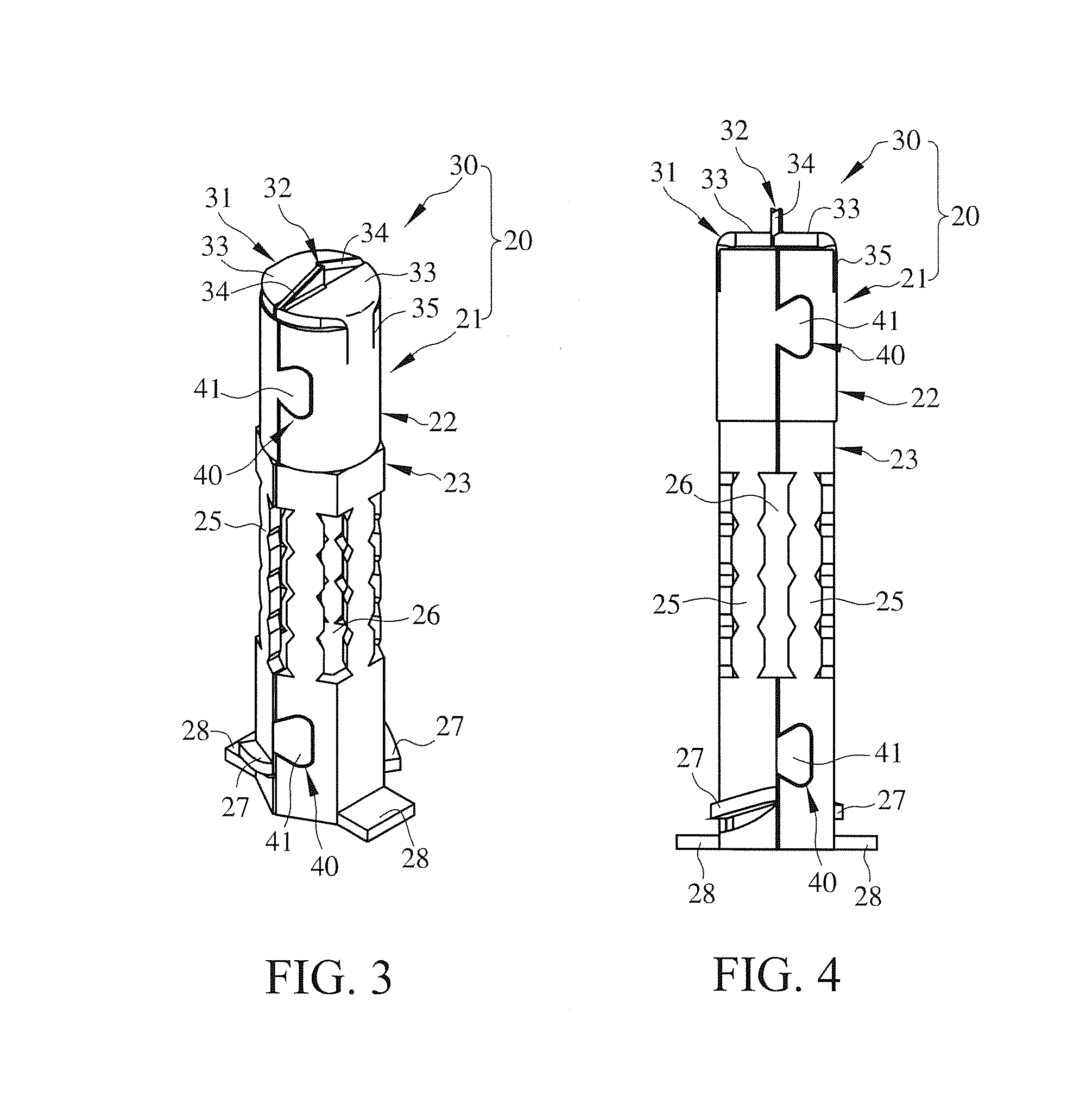

[0025]Please refer to FIGS. 3 to 6. A self-drilling expansion fastener 20 according to a preferred embodiment of the present invention is integrally formed of a sheet metal material, and includes an expansion structure 21 and a drill structure 30 located at a head of the expansion structure 21. The expansion structure 21 has a front portion formed into an internally threaded body portion 22 and a rear portion formed into a barrel body portion 23. The internally threaded body portion 22 is a cylindrical hollow body and defines a plurality of internal threads 24.

[0026]The barrel body portion 23 is a hexagonal hollow body and internally defines a hex bore. The barrel body portion 23 includes a plurality of laterally spaced force-distributing bars 25. Once the barrel body portion 23 is subjected to an axial pull, stress occurs at the force-distributing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com