Shoe for a ski boot and related production method

a production method and technology for ski boots, applied in the field of ski boots, can solve the problems of loss of comfort, inability to meet the needs of foot comfort, so as to ensure foot comfort, breathability, thermal insulation and water repellency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

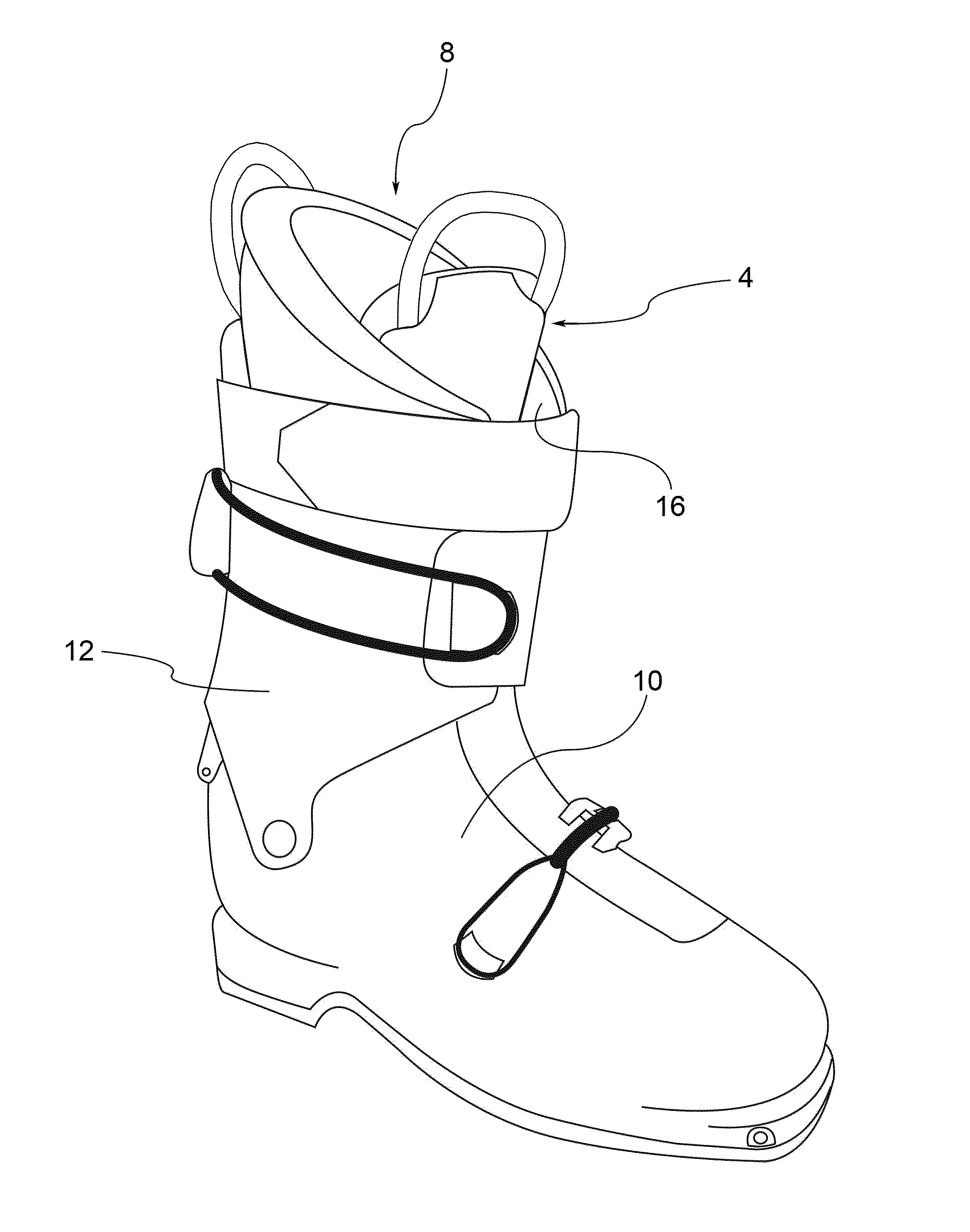

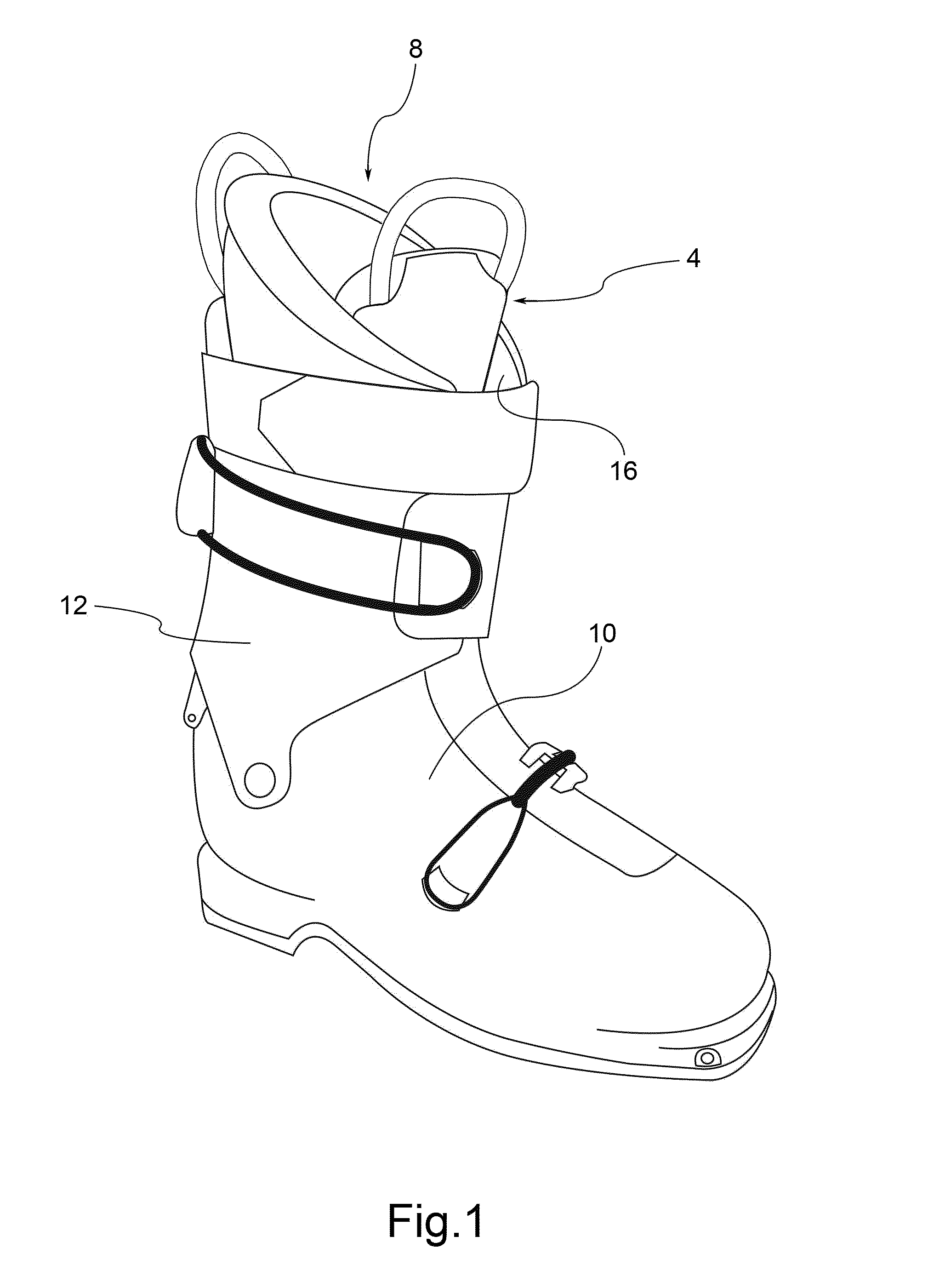

[0028]With reference to the above figures, the reference number 4 globally indicates a shoe for ski boot 8.

[0029]For the purposes of this invention, it should be clarified that the term ski boot must be considered in the broad sense, encompassing any type of ski, ski touring or telemark skiing or similar boot.

[0030]Typically the ski boot 8 comprises a shell 10 and a cuff 12, hinged to the shell 10, in correspondence of the malleolus of the user's foot.

[0031]The boot 8, of any type, comprises an inner wall 16 suitable to interface with said shoe 4, which constitutes an interface between the boot 8 and the user's foot. Said inner wall 16 defines a compartment of the boot suitable to contain the shoe.

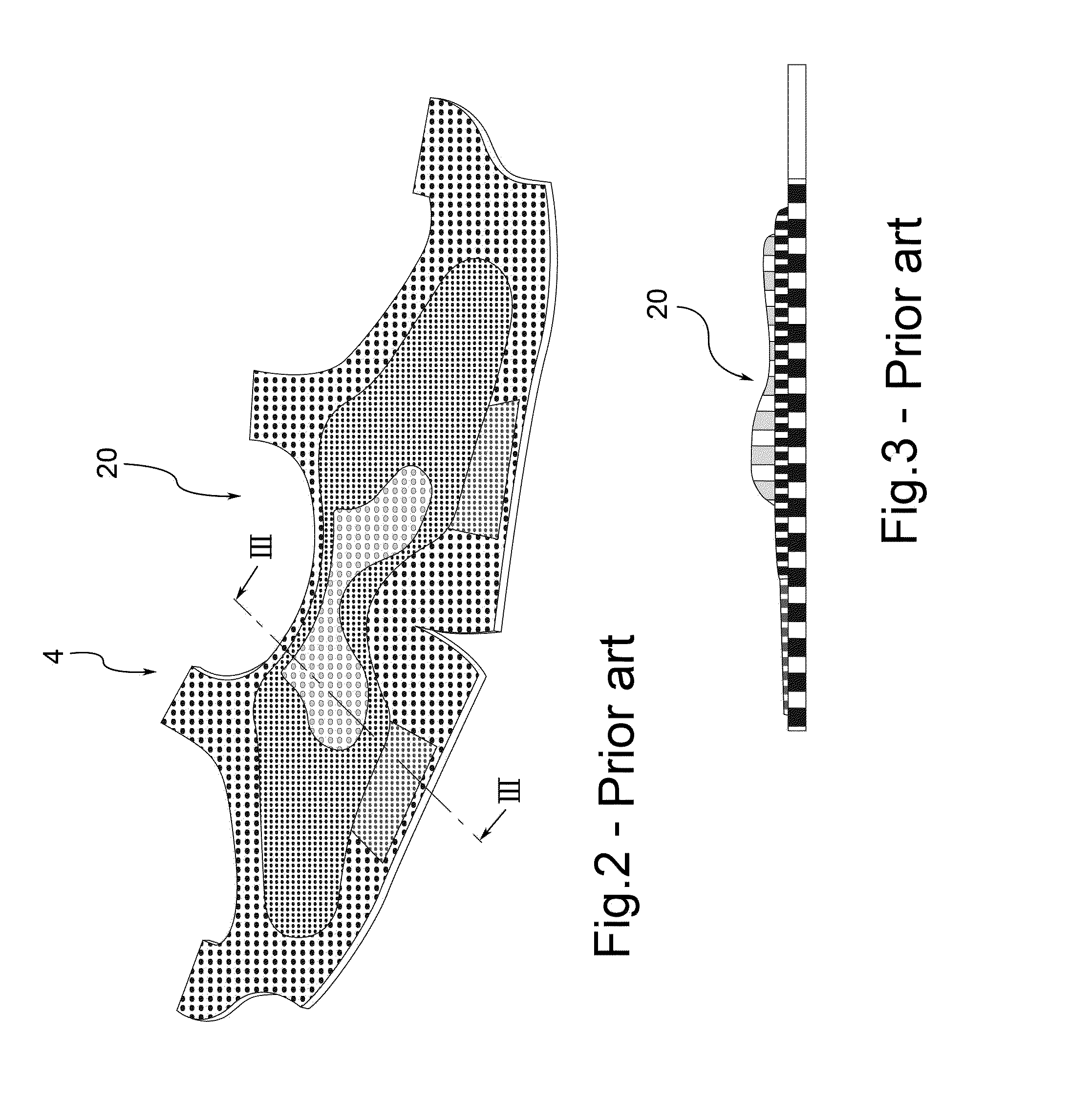

[0032]The shoe 4 comprises a breathable portion 20 equipped with a first outer layer 24, suitable to interface with an associable ski boot 8, and a second inner layer 28, at least partially overlapped and fastened to the first outer layer 24.

[0033]The overlapping layers 24,28 can be fixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com