Substrate processing apparatus, substrate transfer method and substrate transfer device

a technology of substrate and processing apparatus, applied in the direction of storage devices, manipulators, electrical apparatus, etc., can solve the problems of substrate damage, particle generation, and the inability to transfer substrate from a certain place to a certain other place, so as to prevent photo-corrosion and prevent photo-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

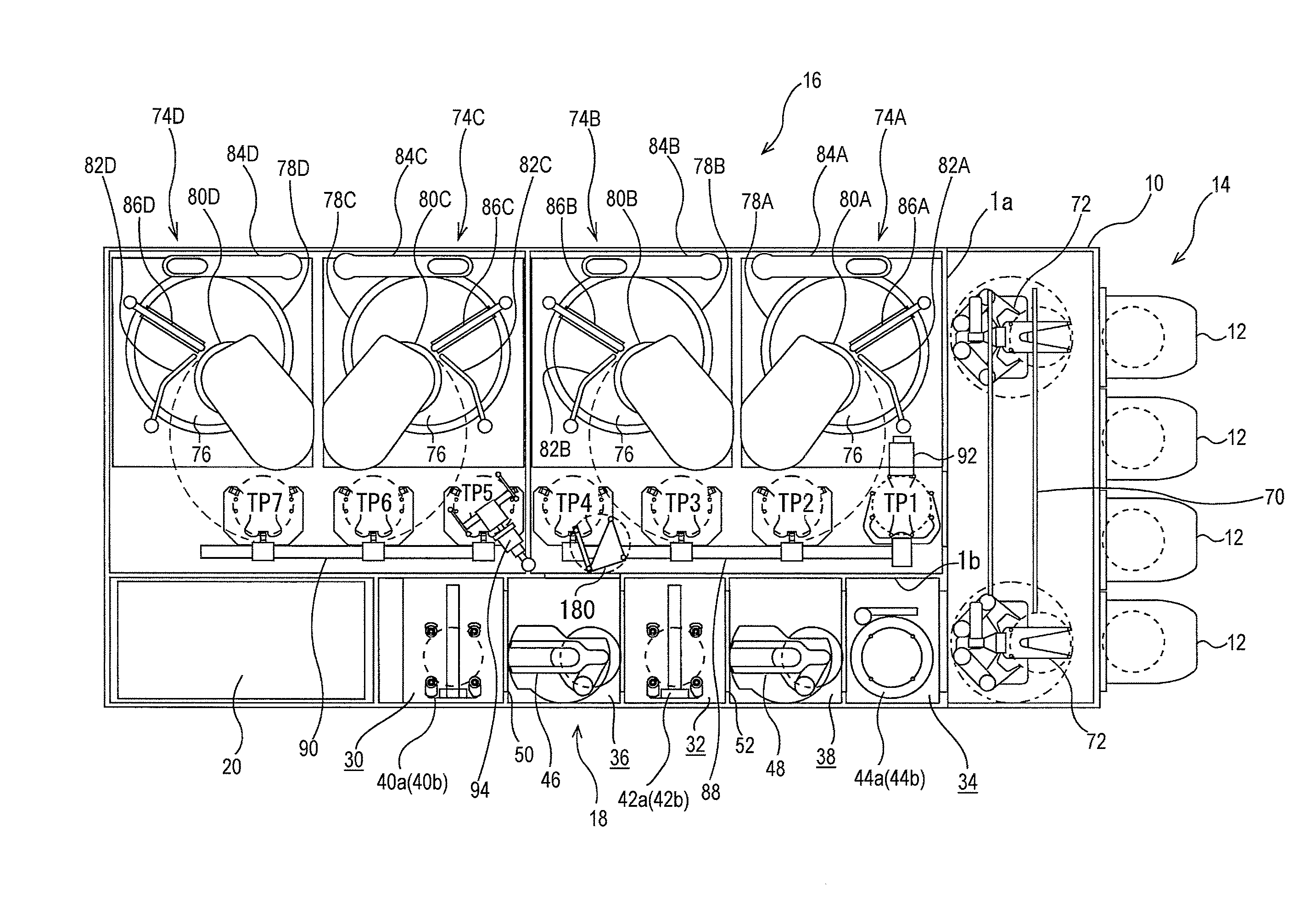

[0046]Preferred embodiments of the present invention will now be described in detail with reference to the drawings. The following description illustrates an exemplary case in which a substrate processing apparatus according to the present invention is applied to a cleaning section provided in a CMP (chemical mechanical polishing) apparatus which removes an unnecessary portion of a copper plated film formed on a surface of a substrate, such as a semiconductor wafer, i.e. a portion other than a copper plated film embedded in interconnect trenches and vias, thereby forming copper interconnects.

[0047]A substrate processing apparatus according to the present invention can, of course, be applied to a cleaning section of an apparatus different from a CMP apparatus or to a processing section different from a cleaning section if such a cleaning section or processing section is required to prevent photo-corrosion due to exposure to light.

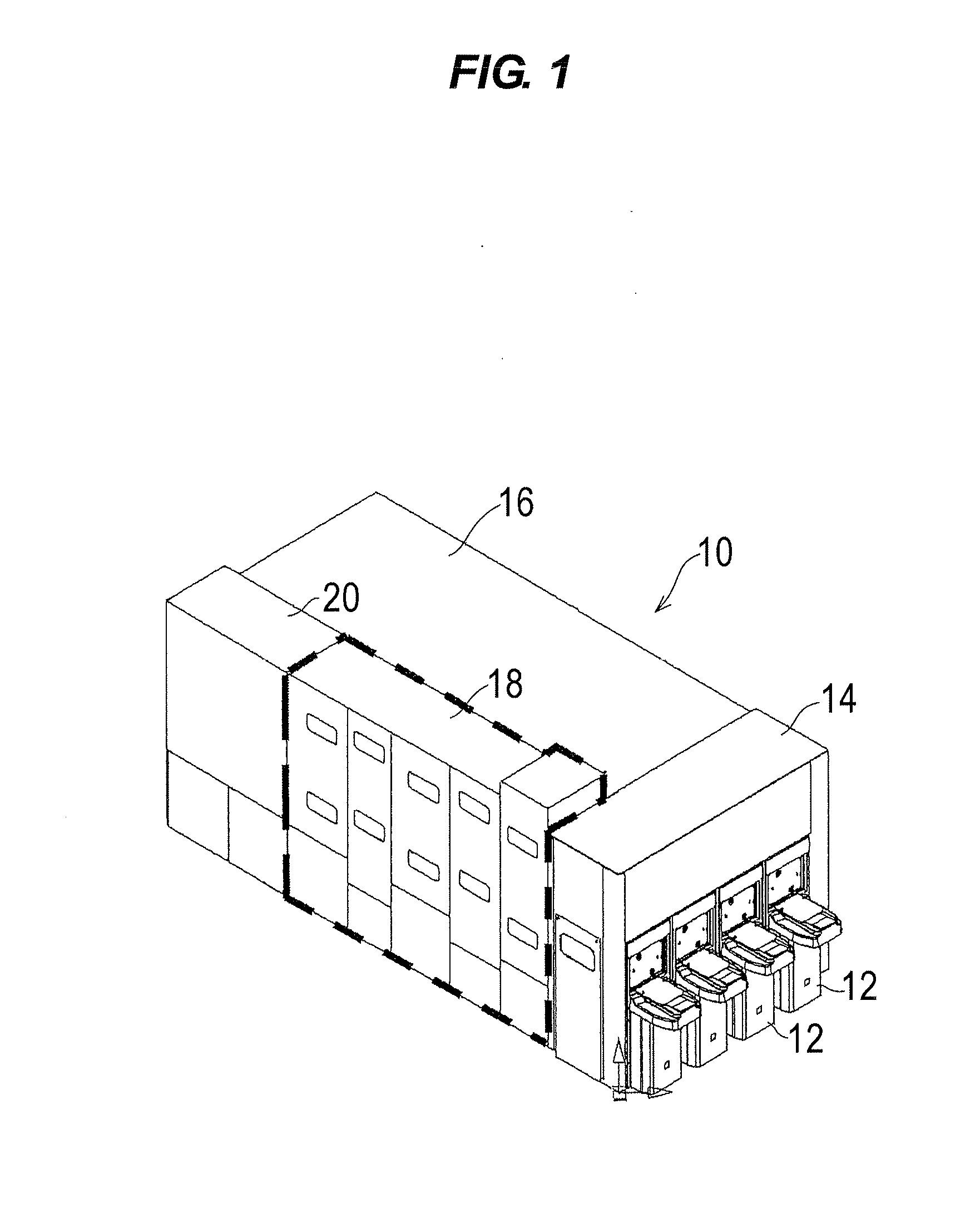

[0048]FIG. 1 shows an overall external view of a CMP a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com