Floor mat and particulate laden material washing apparatus and method

a technology for floor mats and washing apparatuses, applied in other washing machines, detergent compositions, textiles and papermaking, etc., can solve the problems of resort hotel laundry, problems for laundry, and large quantities of heavy dirt or sand on the floor mats, so as to improve the performance of the washing machine, eliminate any build-up of sand or organic materials, and maintain the effect of washing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

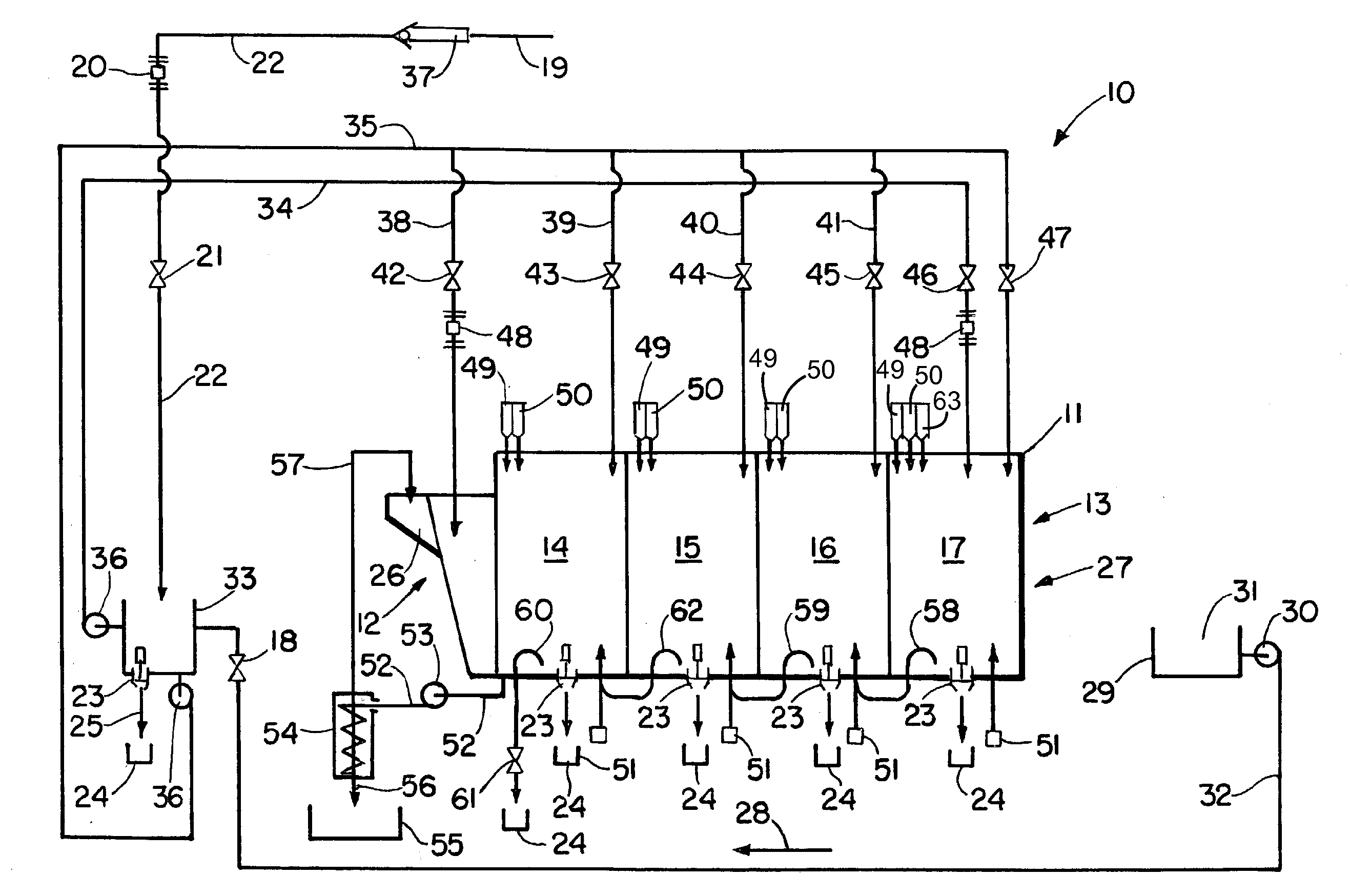

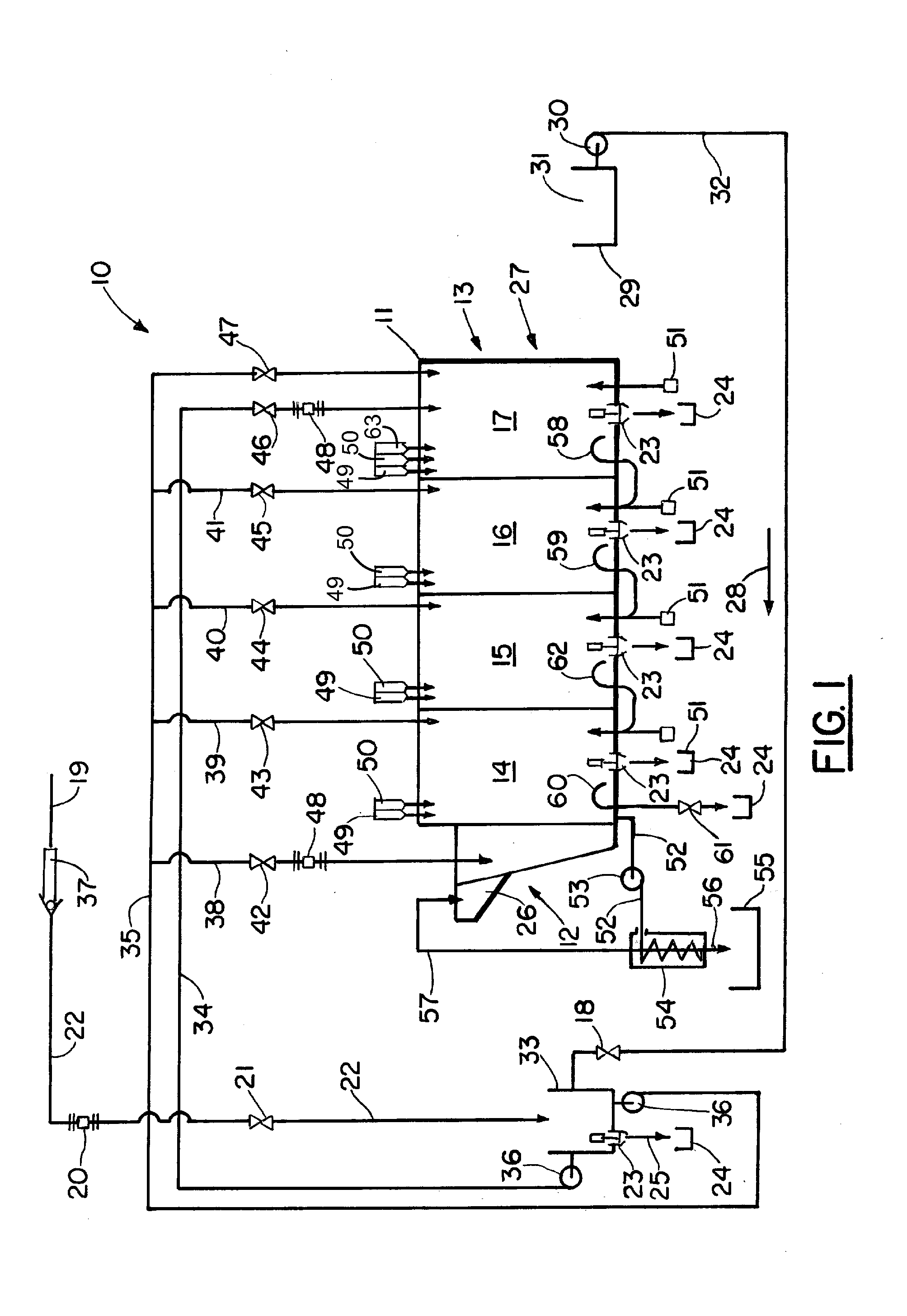

[0035]FIG. 1 shows a preferred embodiment of the apparatus of the present invention designated by the numeral 10. Washing apparatus 10 is used to wash floor mats that can contain undesirable material, particulate material such as sand, organic matter and the like. The apparatus of the present invention employs a multiple module tunnel washer 11. Tunnel washer 11 can be as shown and described in any one of the following US patents, each of which is incorporated herein by reference: U.S. Pat. Nos. 4,236,393; 4,485,509; 4,522,046; 5,211,039; 5,454,237; 7,971,302; 8,166,670; 8,336,144; 8,370,981; 8,365,435; and 8,689,463.

[0036]Tunnel washer 11 has an inlet end portion 12 with hopper 26 and an outlet end portion 13. The tunnel washer 11 provides a plurality of modules 14-17. The first module is module 14. The second module is module 15. The third module is module 16. The final module is module 17. It should be understood that more than four (4) modules can be provided. Fluid impregnated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com