Systems and Methods for Restricting Fluid Flow in a Wellbore with an Autonomous Sealing Device and Motion-Arresting Structures

a wellbore and fluid flow technology, applied in the direction of fluid removal, borehole/well accessories, survey, etc., can solve the problems of increasing the difficulty and/or cost of setting the required number of isolation plugs, affecting the economic and/or efficient stimulation of the subterranean formation, and ineffective under others

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

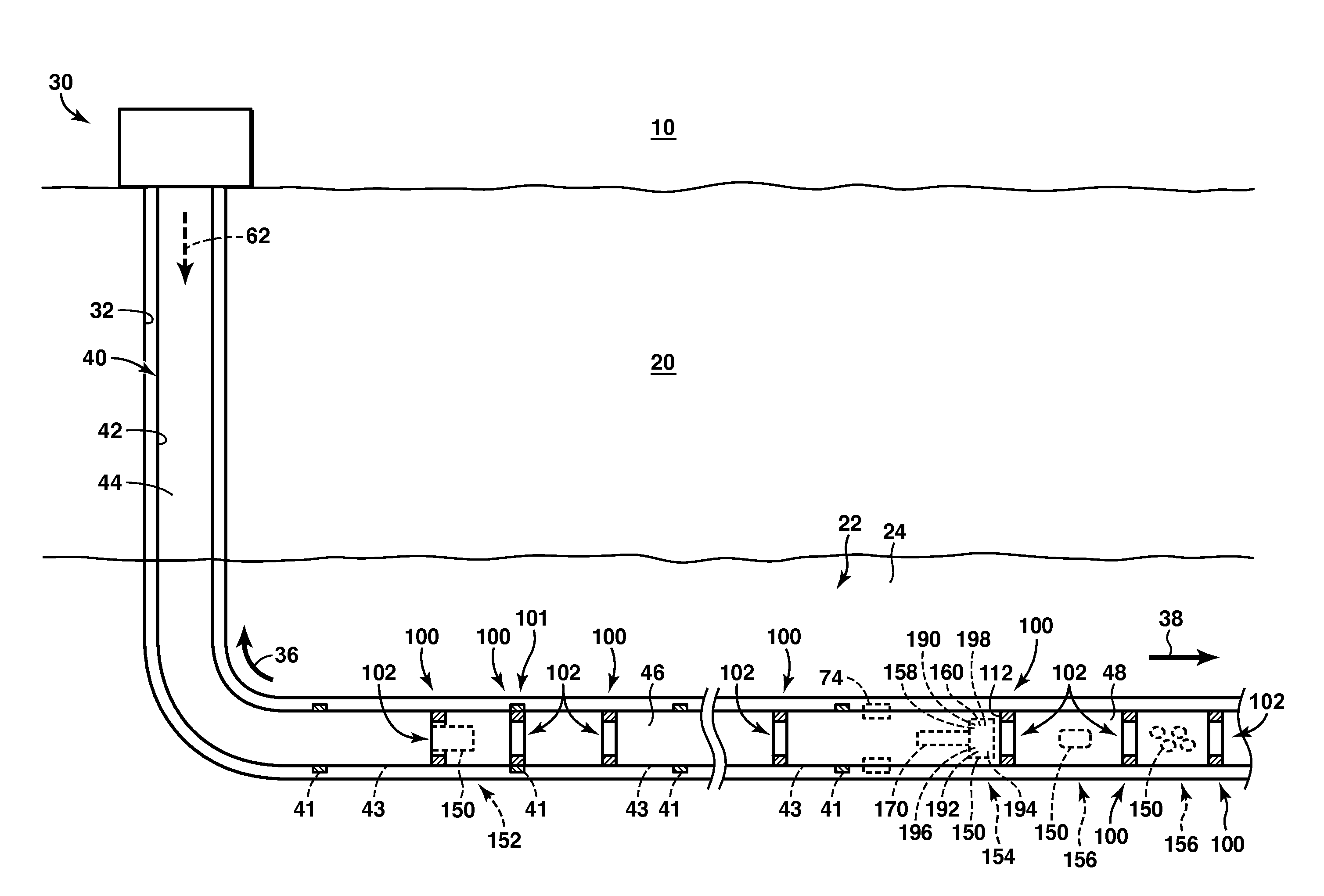

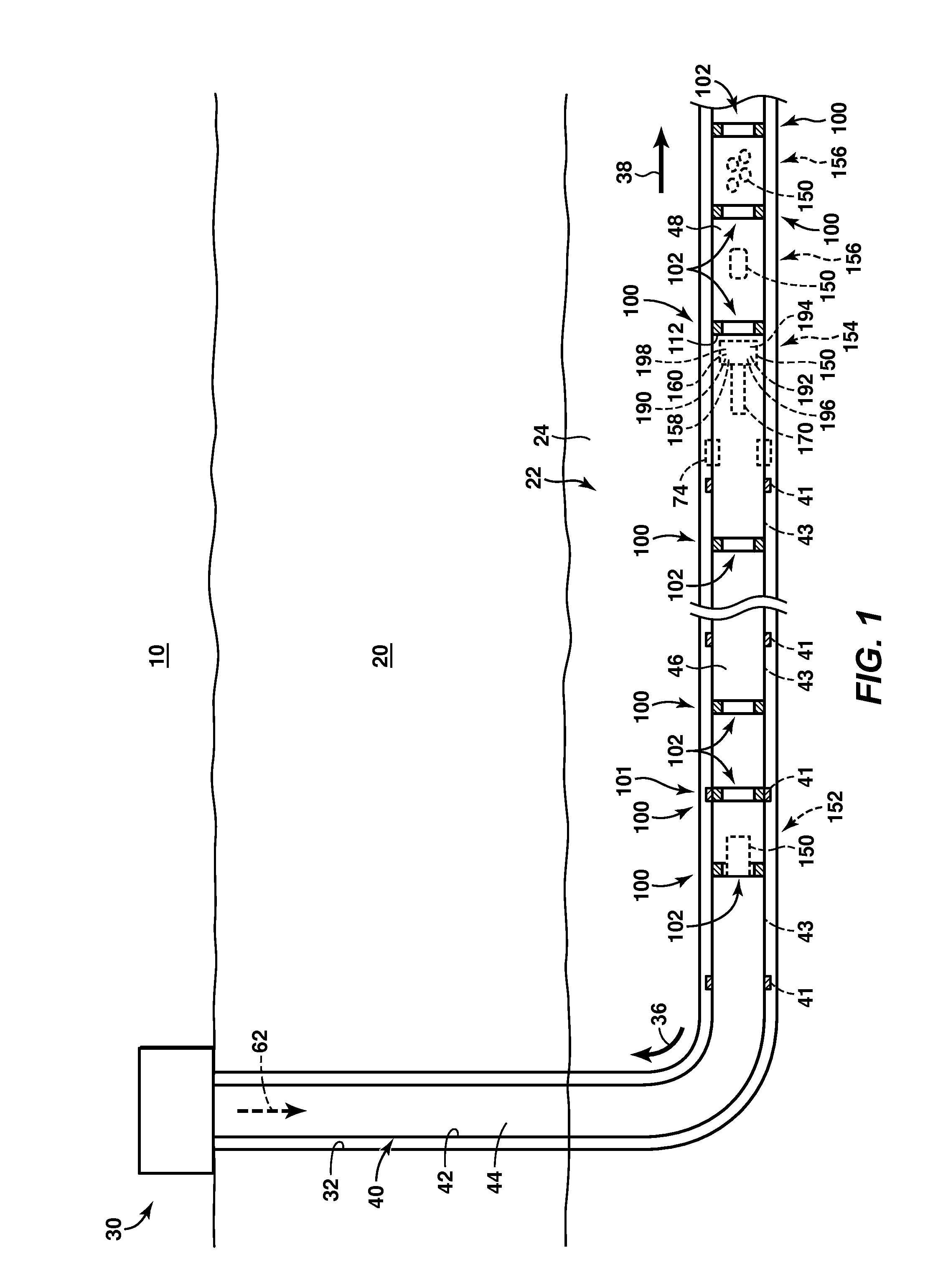

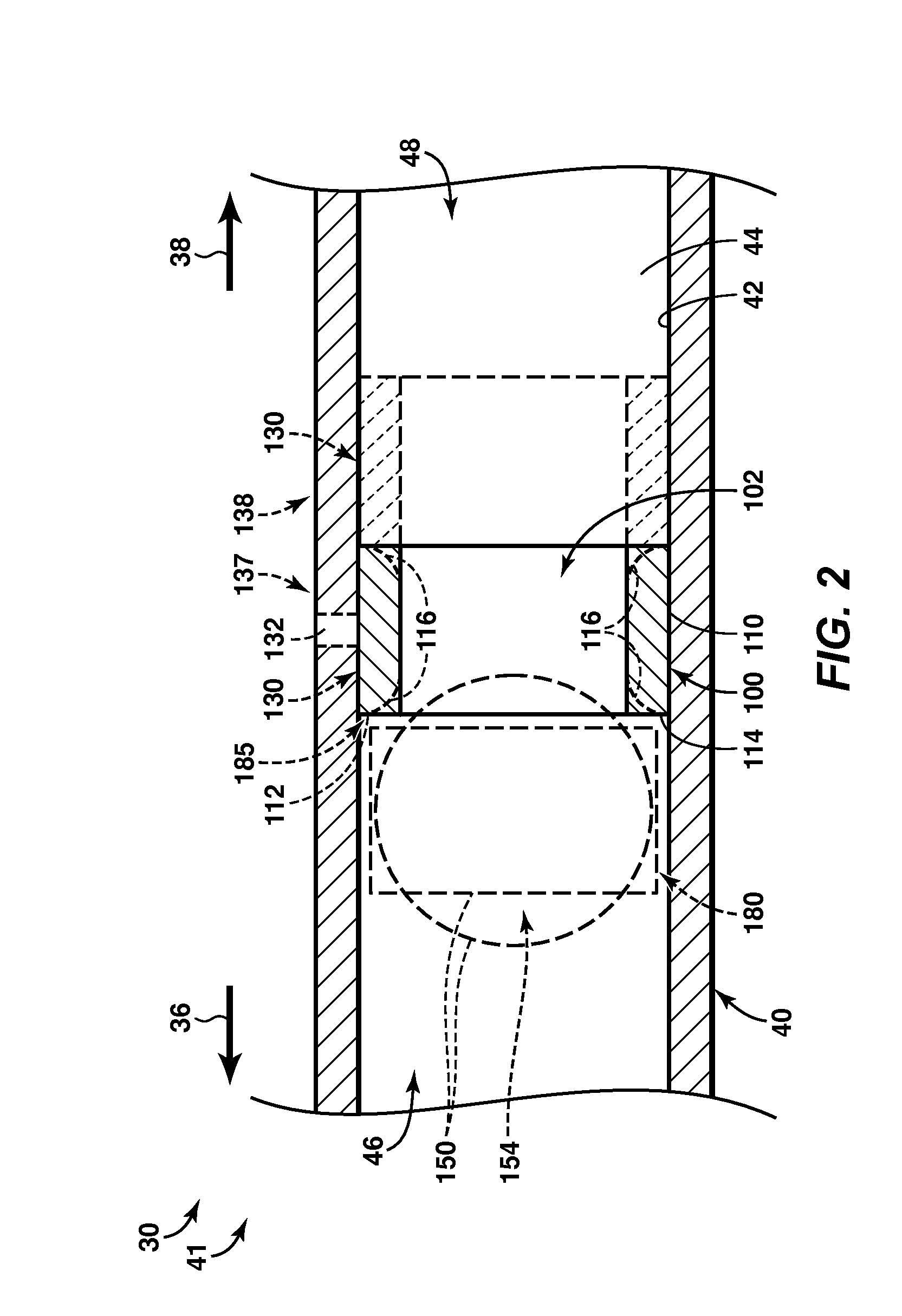

[0028]FIGS. 1-9 provide illustrative, non-exclusive examples of hydrocarbon wells 30 according to the present disclosure and / or of components of hydrocarbon wells 30, such as motion-arresting structures 100 and / or autonomous sealing devices 150. Elements that serve a similar, or at least substantially similar, purpose are labeled with like numbers in each of FIGS. 1-9, and these elements may not be discussed in detail herein with reference to each of FIGS. 1-9. Similarly, all elements may not be labeled in each of FIGS. 1-9, but reference numerals associated therewith may be utilized herein for consistency. Elements, components, and / or features that are discussed herein with reference to one or more of FIGS. 1-9 may be included in and / or utilized with any of FIGS. 1-9 without departing from the scope of the present disclosure.

[0029]In general, elements that are likely to be included in a given (i.e., a particular) embodiment are illustrated in solid lines, while elements that are op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com