Composite container, package body, and method for manufacturing composite container

Inactive Publication Date: 2015-02-12

CHOKOKU PLAST CORP

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0062]The present invention can provide a composite container, as represented by a composite container which has a gas barrier property, an anti-moisture property, a shape retaining property, an ant

Problems solved by technology

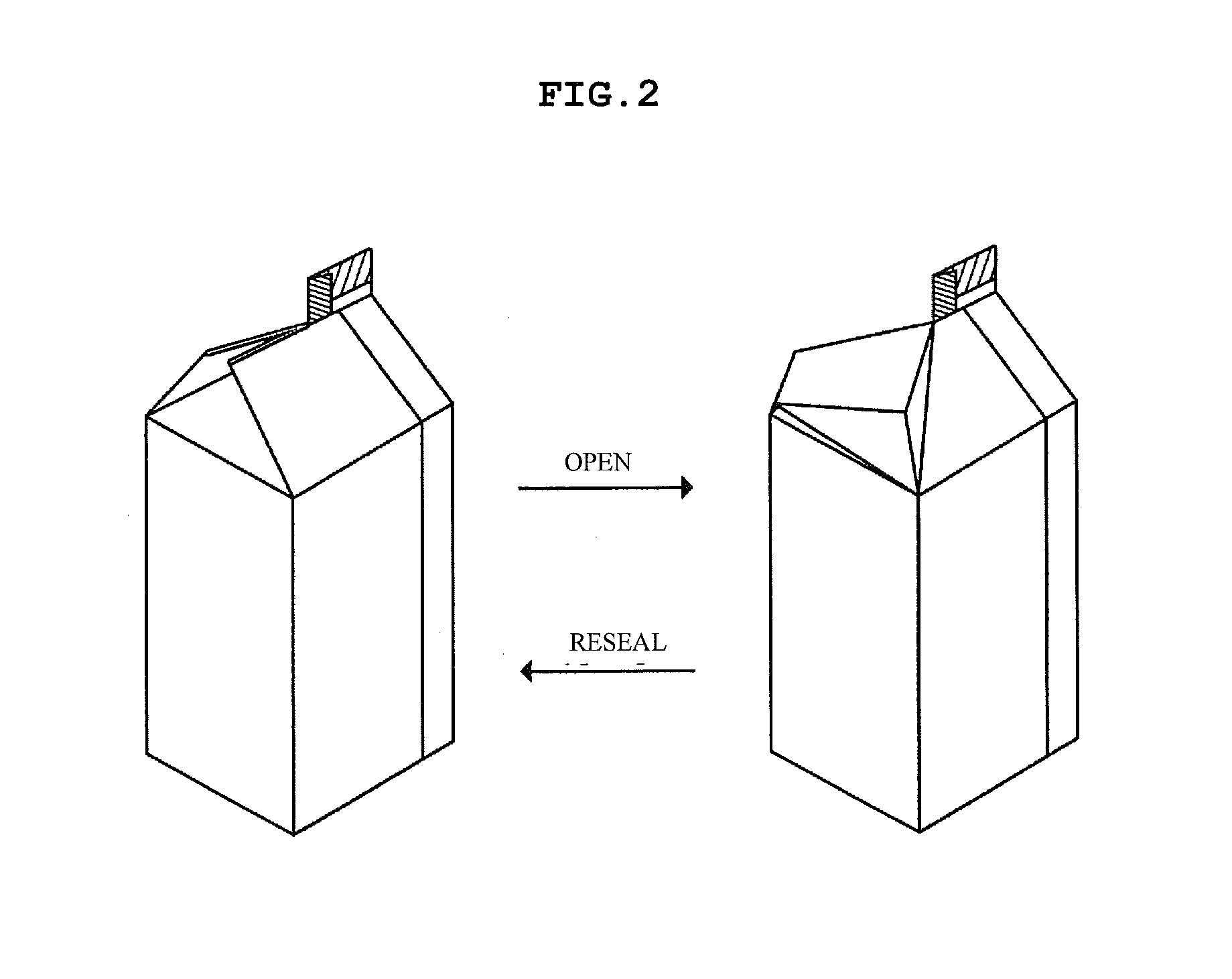

However, since the flexible packaging material has no shape retaining property, the shape and volume thereof change significantly with respect to those of the original package body, and the flexible packaging material cannot be smoothly accommodated in the outer packaging material, or in some cases the outer packaging material is deformed and the flexible packaging material cannot be accommodated successfully.

For this reason, once the conventional composite container has been opened, it is thereafter used while the appearance of the outer packaging mat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Content | aaaaa | aaaaa |

Login to View More

Abstract

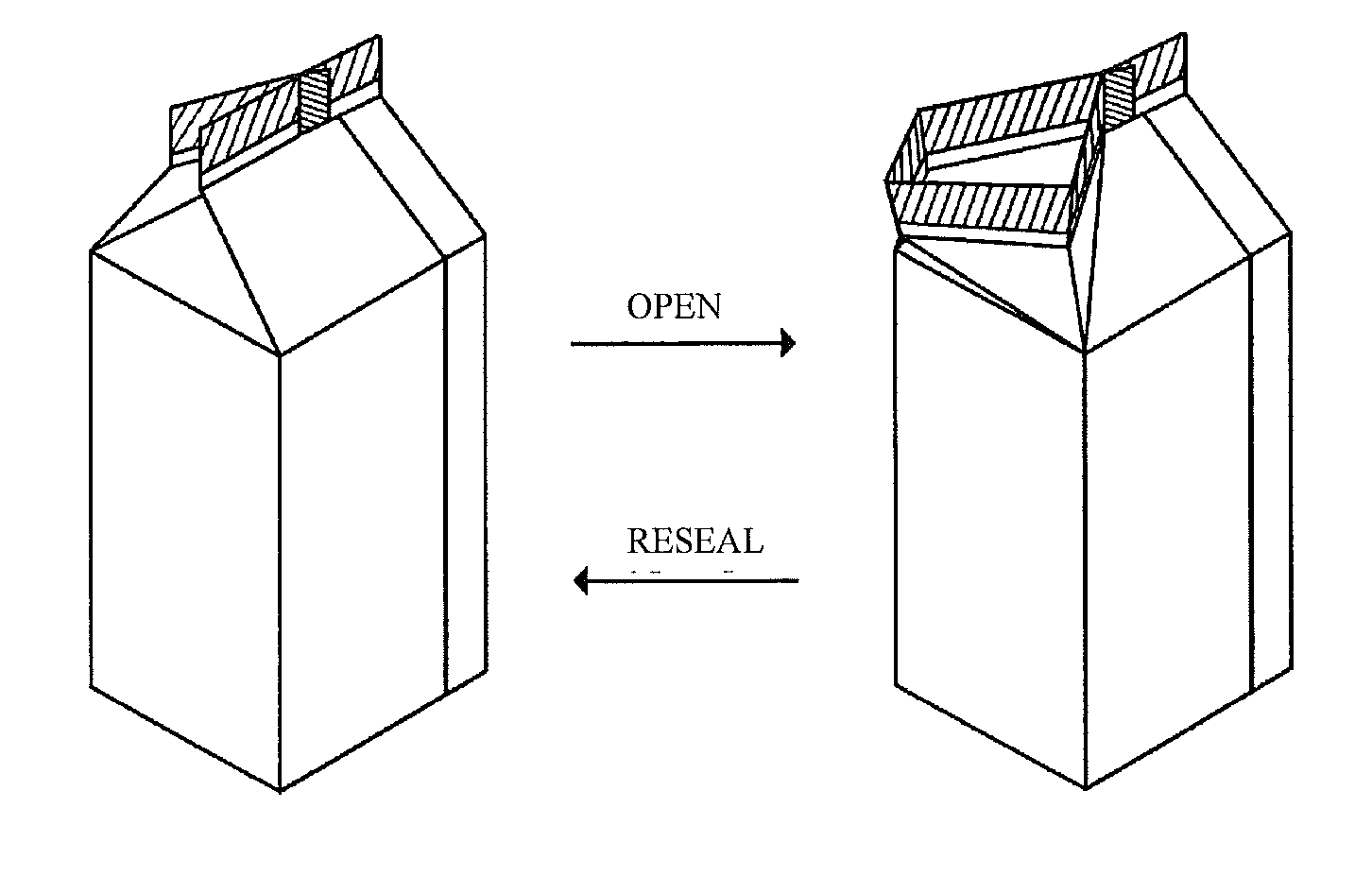

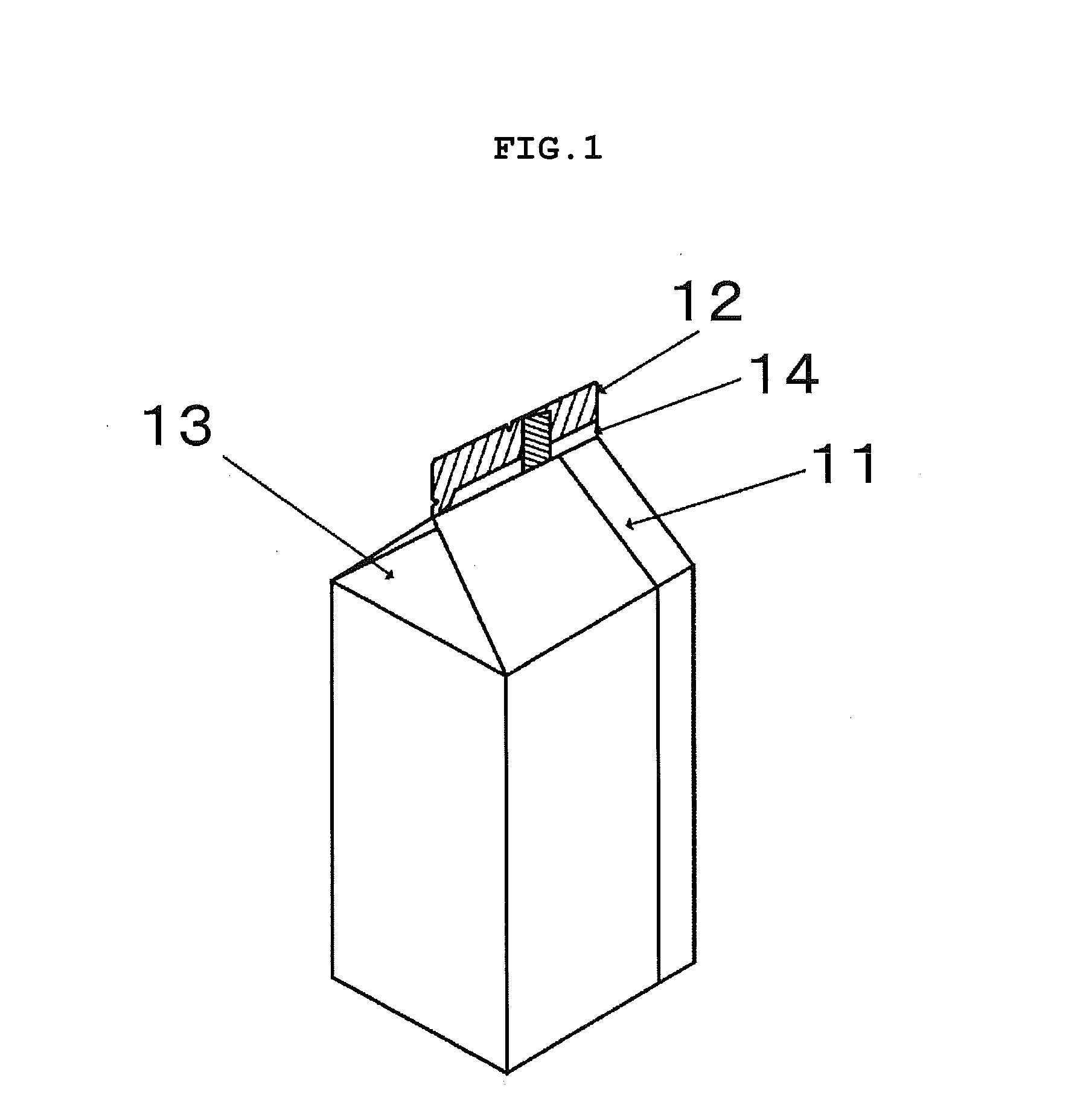

The objective of the present invention is to provide a composite container, as represented by a composite container which has a gas barrier property, an anti-moisture property, a shape retaining property, an anti-shock property, an easy-to-open property, and a resealing function, can be easily opened, and facilitates the extraction of the contents.

A composite container having a gable top shape in which a paper board is attached to an outer peripheral surface of a pillow type bag constituted by a resin film and having an end seal section and a center seal section, wherein

- the paper board is attached to the resin film in at least a body portion of the composite container;

- in an upper part of the composite container, the resin film and the paper board are gazette-like folded while being attached to each other in such a manner that an end portion of the resin film protrudes from an end portion of the paper board, and the end portion of the resin film forms the end seal section; and

- an inner peripheral surface of the paper board of the composite container is attached at an entire surface or part thereof to the resin film below the end seal section protruding from the end portion of the paper board.

Description

BACKGROUND OF THE INVENTION[0001]1. Field of the Invention[0002]The present invention relates to a composite container constituted by a resin film and a paper board and to a manufacturing method thereof.[0003]2. Description of the Related Art[0004]A method that has been conventionally widely used for providing food and confectionary involves accommodating the contents in a flexible packaging material such as a plastic film, and then further accommodating the package body in a rigid outer packaging material (outer box) made of paper, or the like, for distribution. In such composite containers, the contents can be protected from damage, or the like, by the outer packaging material while, for example, gas and moisture barrier properties are ensured by the flexible packaging material. Further, since the outer packaging material has a shape retaining property, the composite containers can be arranged neatly in the stores.[0005]With the above-described composite container, first, the oute...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65D5/40B65B7/18B65D5/74B65B3/02B65D5/56B65D5/60

CPCB65D5/40B65D5/563B65B7/18B65D5/741B65B3/025B65D5/606B65B9/06B65D75/525B65D5/068B65D5/4279

Inventor ASAI, KENICHI

Owner CHOKOKU PLAST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com