Work vehicle boom assembly providing improved visability

a technology for working vehicles and booms, which is applied in the direction of mechanical machines/dredgers, soil-shifting machines/dredgers, transportation and packaging, etc. it can solve the problems of poor operator visibility to the area being worked, the boom interferes with, if not almost completely blocks, and the sightline between the vehicle cabin and the implement is another obstacle, so as to achieve the effect of better sight lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The following describes one or more example constructions of a boom assembly 30 and work vehicle 32, as shown in the accompanying figures of the drawings described briefly above. Various modifications to the example construction(s) may be contemplated by one of skill in the art.

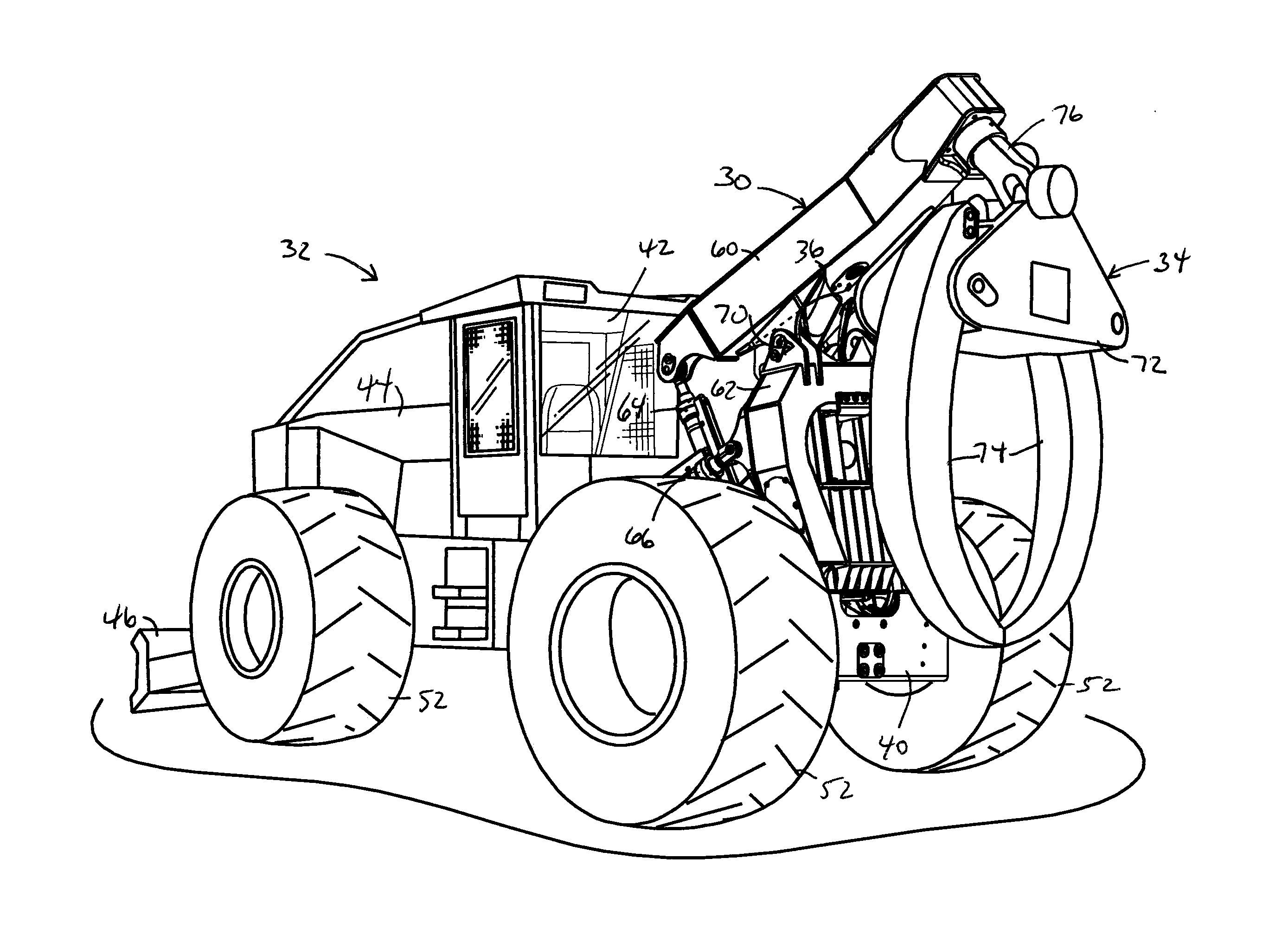

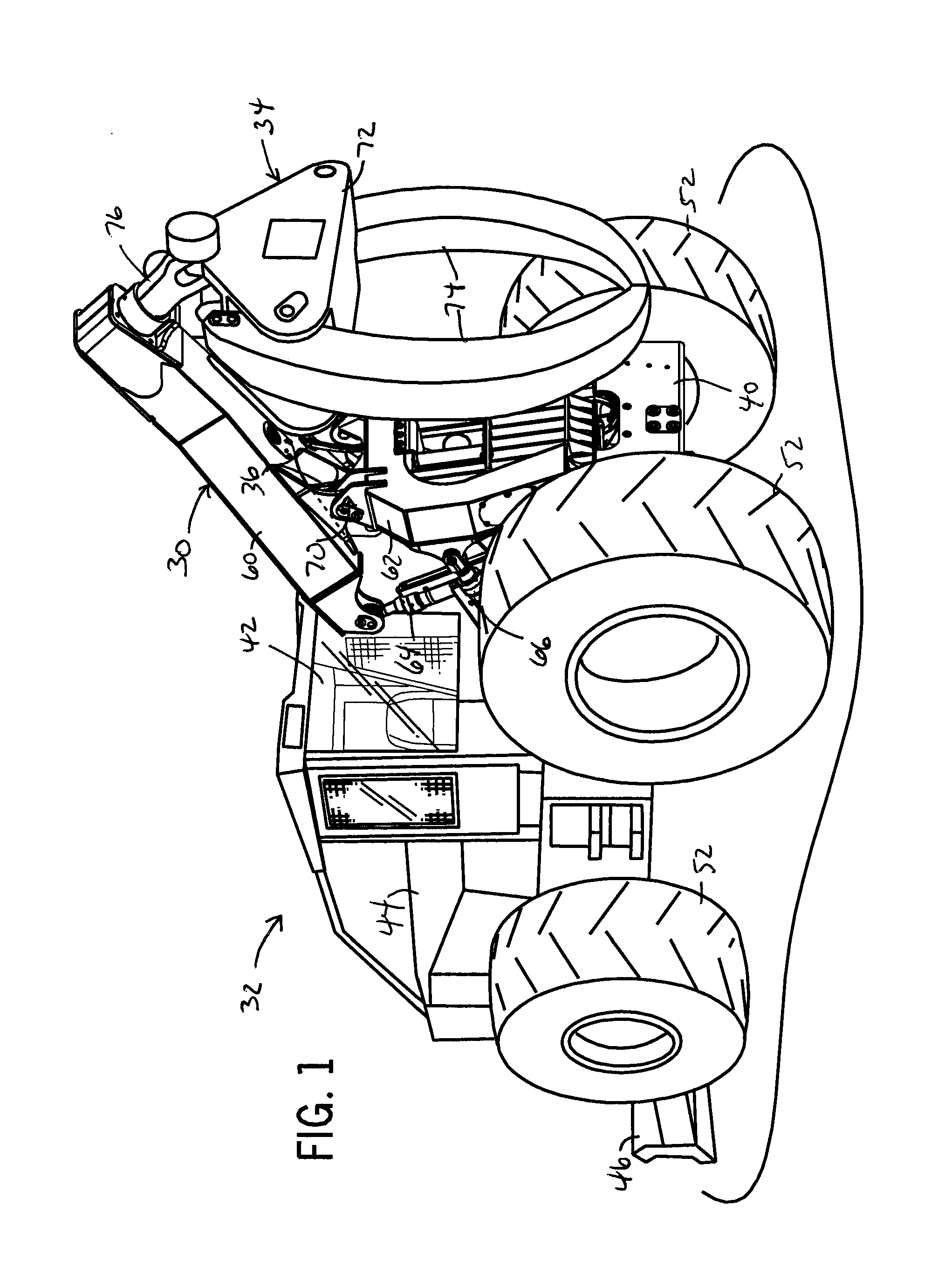

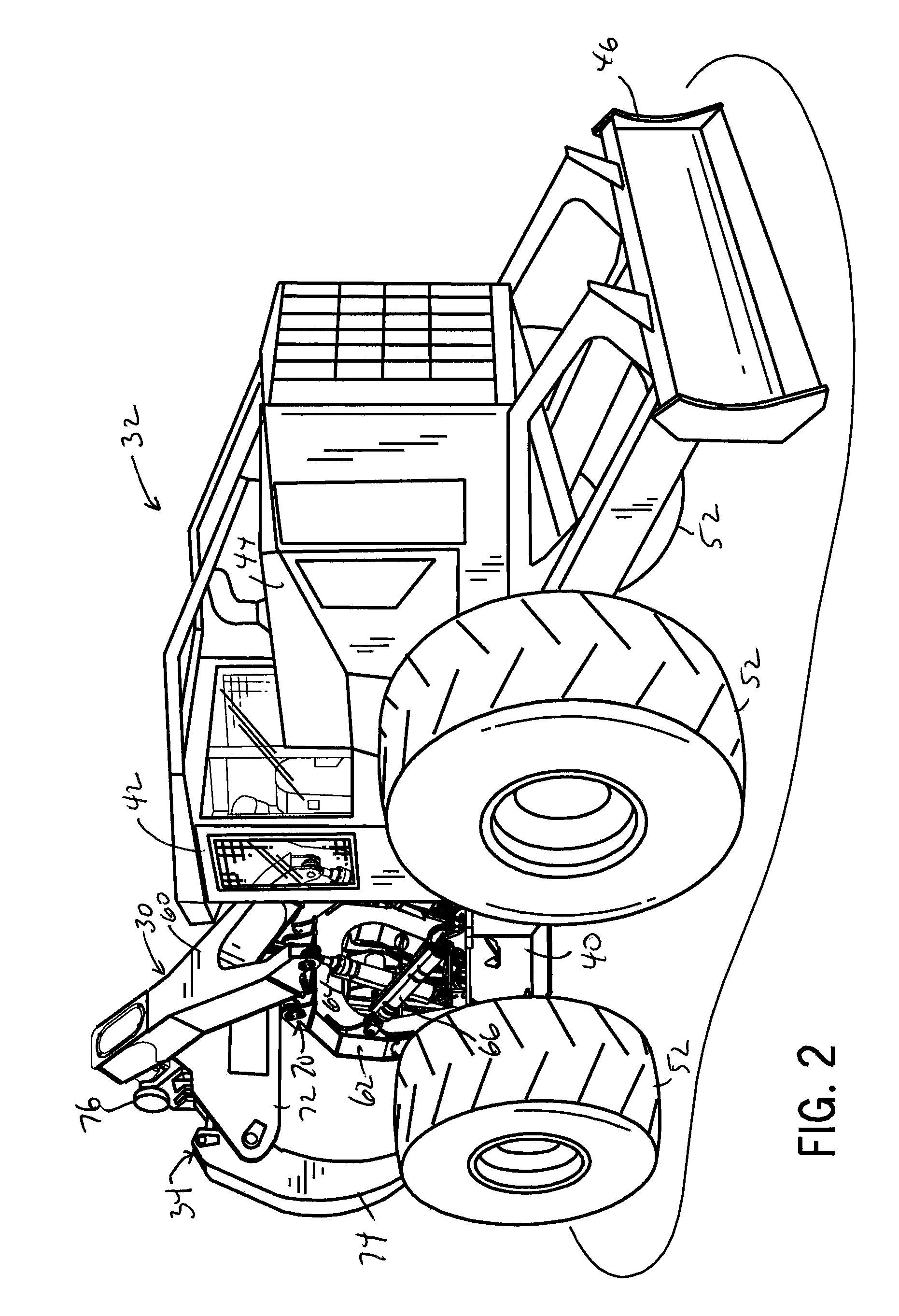

[0028]FIGS. 11-14 show an example application of the boom assembly 30 incorporated into the work vehicle 32 which powers and controls an implement attachment 34 through a bundle of electric and hydraulic working lines 36. In the example shown in FIGS. 1-5 and described herein, the work vehicle 32 is a skidder and the implement attachment 34 is a grapple. For simplicity a single machine and attachment are described herein as an example application. However, the boom assembly 30 can be utilized with various work vehicles and implements, including with tractors and other agricultural, forestry or construction vehicles with any applicable implement attachment. As such, the terms “work vehicle” and “implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com