Net Knitting Method

a technology of net knitting and needles, applied in the field of net knitting methods, can solve the problems of large holes, poor overall structural strength, and large holes, and achieve the effect of avoiding large holes and increasing the overall structural strength of the n

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

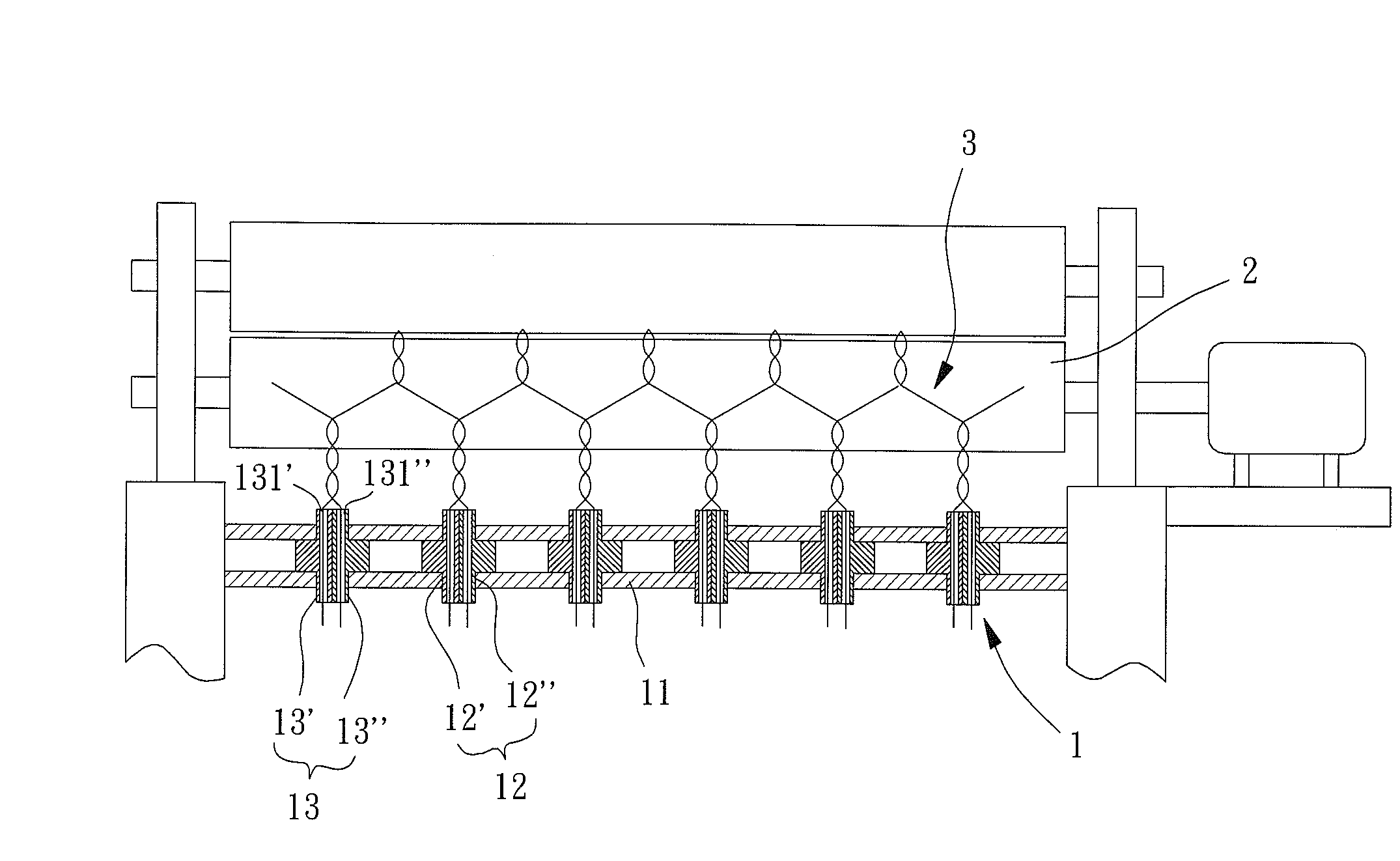

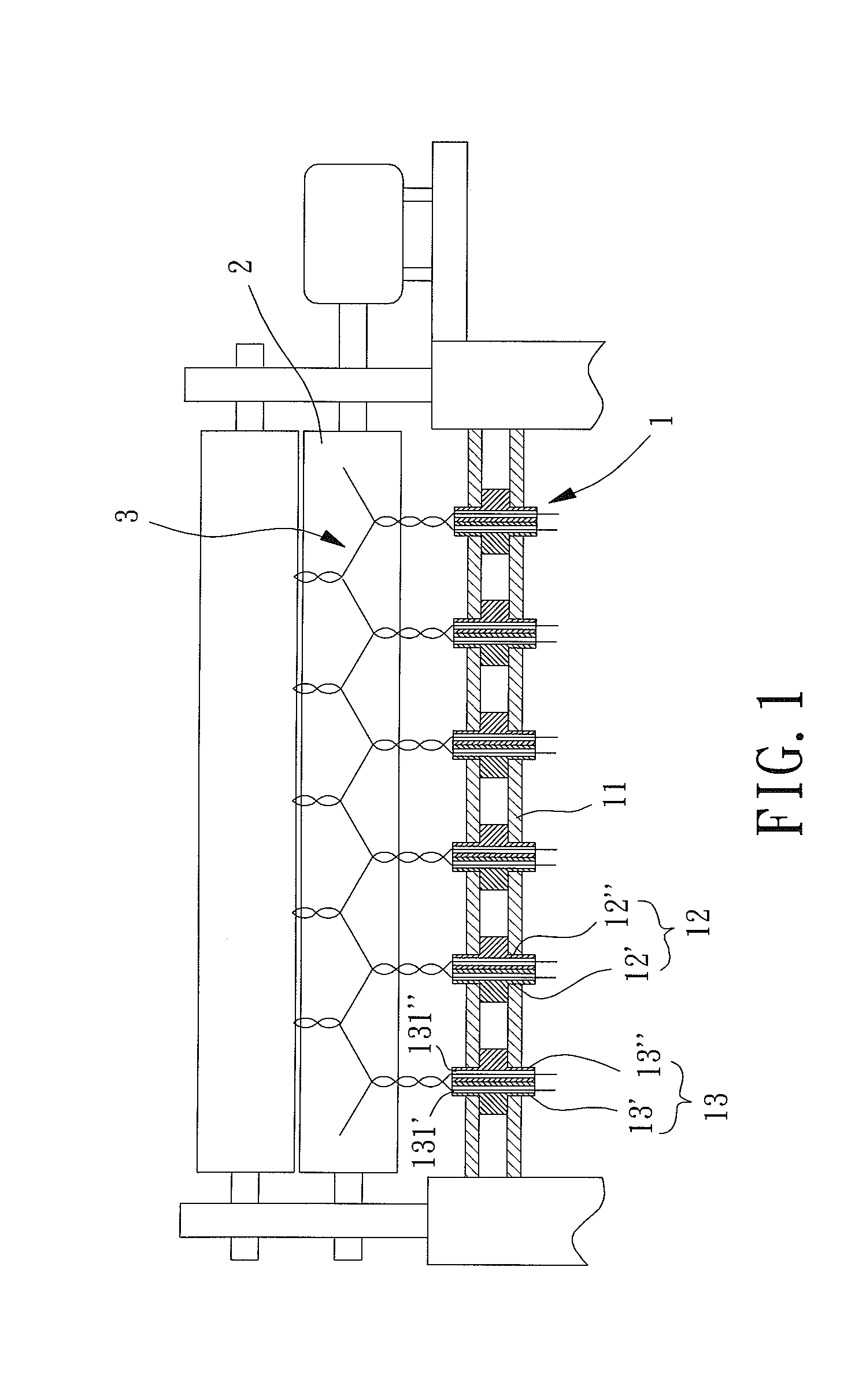

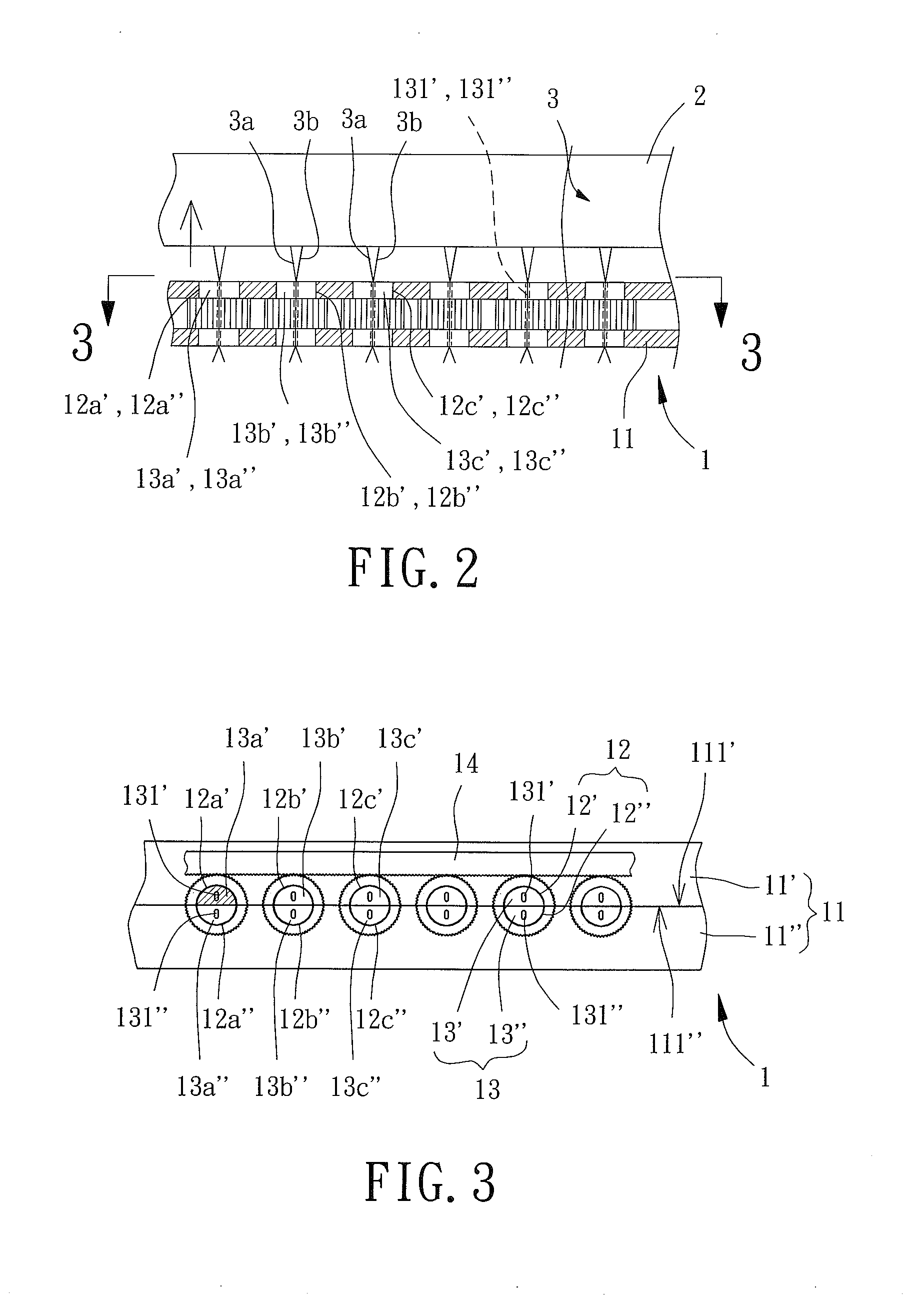

[0049]A method for knitting a net according to the present invention is used on a weaving machine identical to the weaving machine (see FIGS. 1-3) for carrying out the conventional method for knitting a net.

[0050]With reference to FIGS. 1-3, the weaving machine used in the present invention mainly includes a weaving unit 1. The weaving unit 1 includes a base assembly 11, a plurality of weaving holes 12, and a plurality of rotating assemblies 13. The base assembly 11 is comprised of a first base 11′ and a second base 11″. The first base 11′ has a first abutment face 111′ abutting a second abutment face 111″ of the second base 11″, allowing the first base 11′ and the second base 11″ to displace relative to each other along the first abutment face 111′ and the second abutment face 111″. The first base 11′ and the second base 11″ are driven by a power unit to proceed with the relative displacement.

[0051]Each weaving hole 12 is comprised of a first half hole 12′ and a second half hole 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com