Tool string

a tool string and string technology, applied in the field of tool strings, can solve the problems that the couplings known do not provide the necessary connection between advanced tools and tool parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

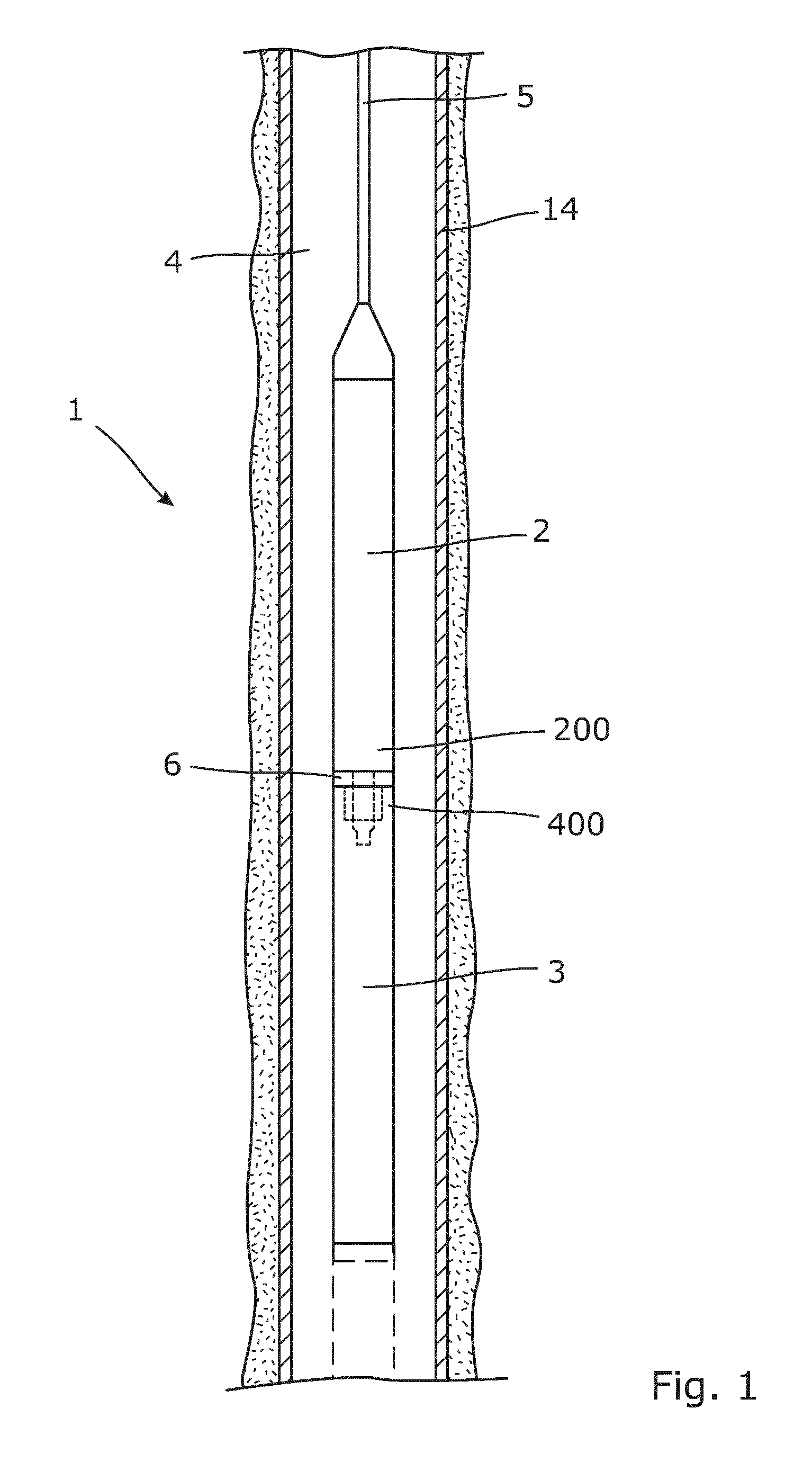

[0035]FIG. 1 shows a tool string 1 being suspended in a well 4 from a wireline 5. The tool string 1 may also be suspended using coiled tubing or by being part of a drill string. The shown well comprises a casing 14, but the tool string 1 may also be used in an uncased well.

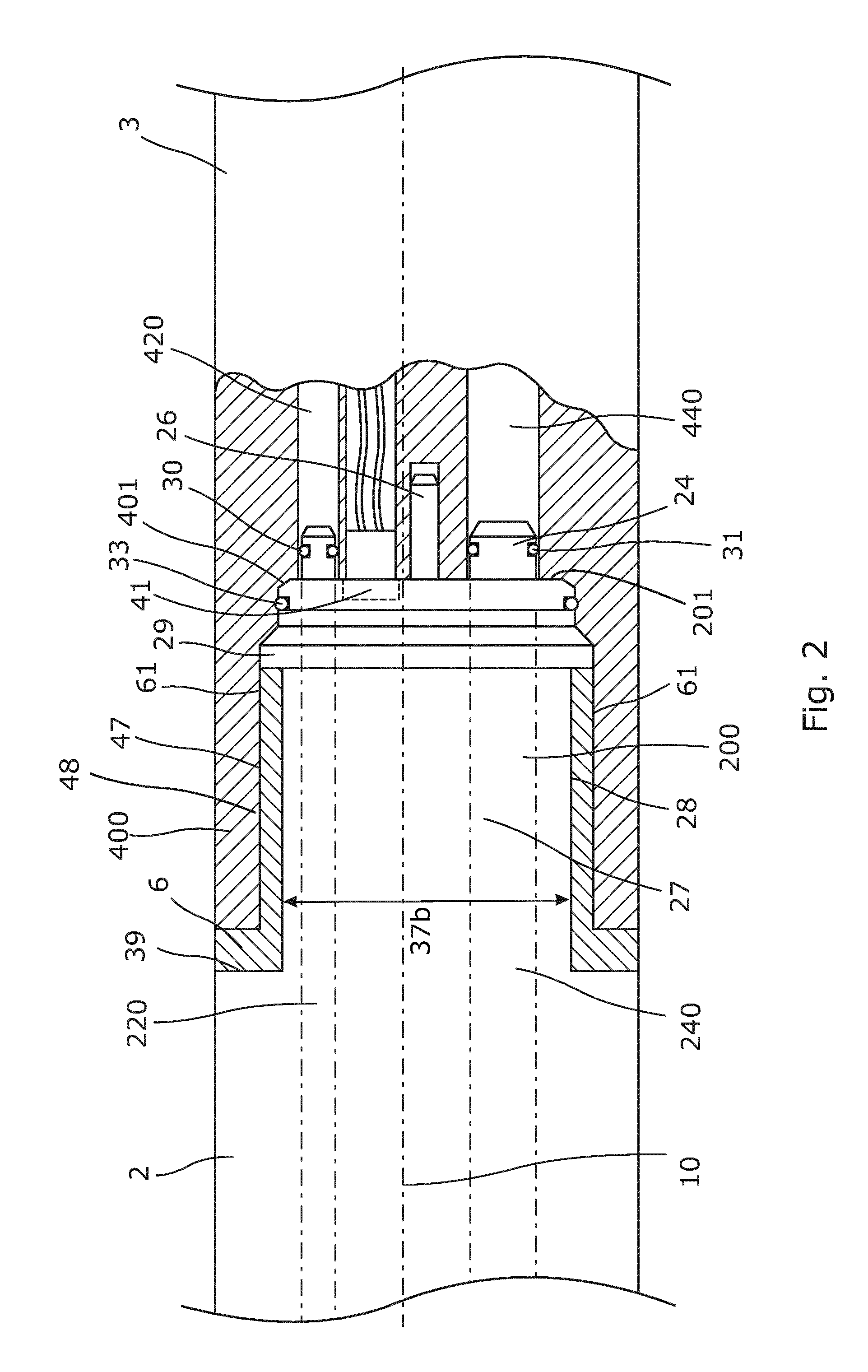

[0036]The tool string 1 extends in a longitudinal direction and comprises at least a first tool string part 2 and a second tool string part 3. A first end 200 of the first string part 2 and a first end 400 of the second string part 3 are connected via a connecting element 6 arranged between the two string parts 2, 3 in the longitudinal direction. The dotted lines in FIG. 1 illustrate how part of the first end 200 of the first string part extends through the connecting element 6 and into the first end 400 of the second string part.

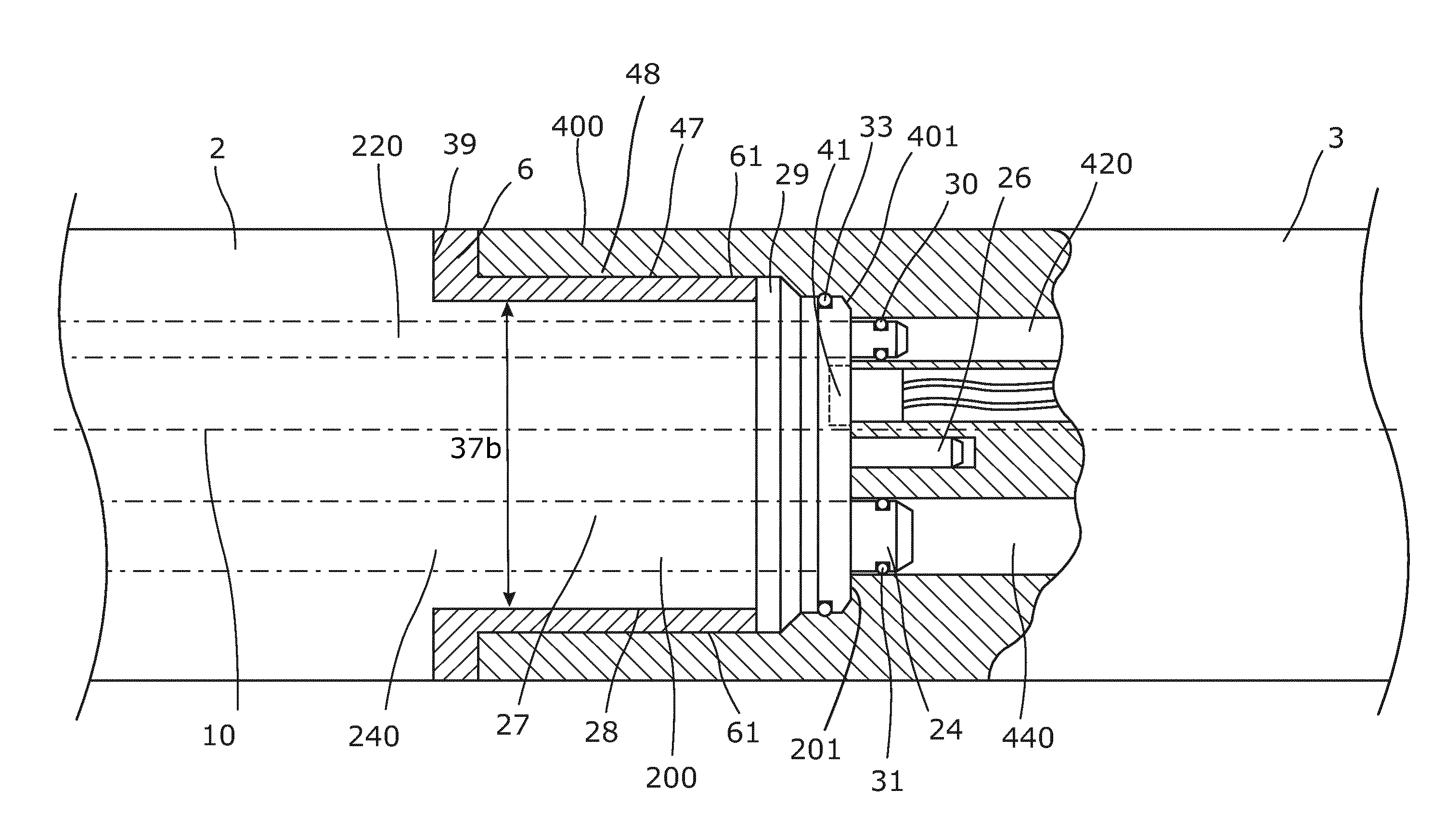

[0037]Referring to FIG. 2, the connection shown in FIG. 1 between the first string part 2 and the second string part 3 will be described in further detail below. For the purpose of clarit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com