Method and apparatus for a product cooler

a technology for product coolers and coolers, applied in the field of product dispensers, can solve the problems of requiring a still larger ice-box, unable to easily fit the “bulk” version into the cooler, and unable to allow spillage, condensate, drips, etc., and achieve the effect of easing the removal of the product packag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

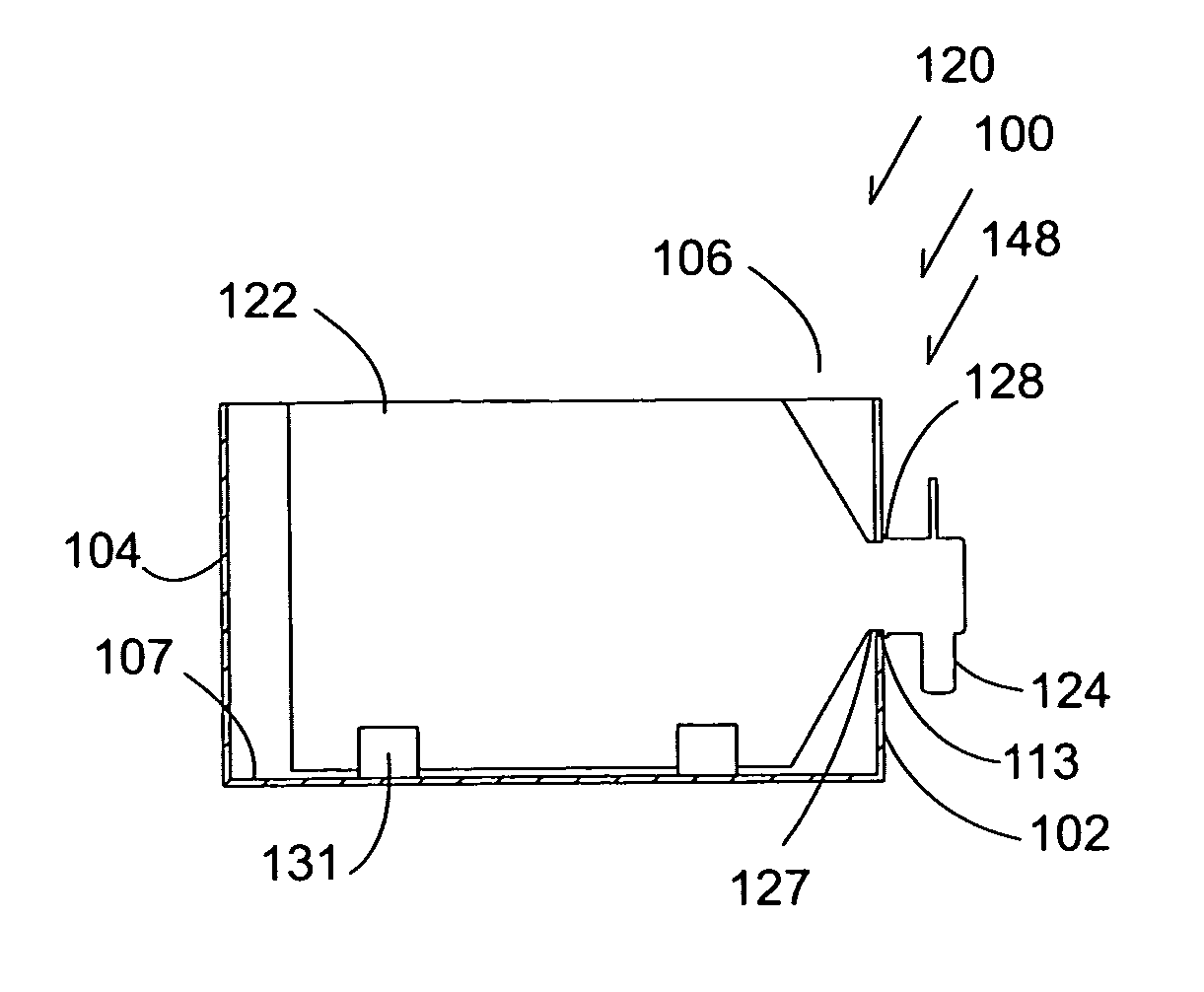

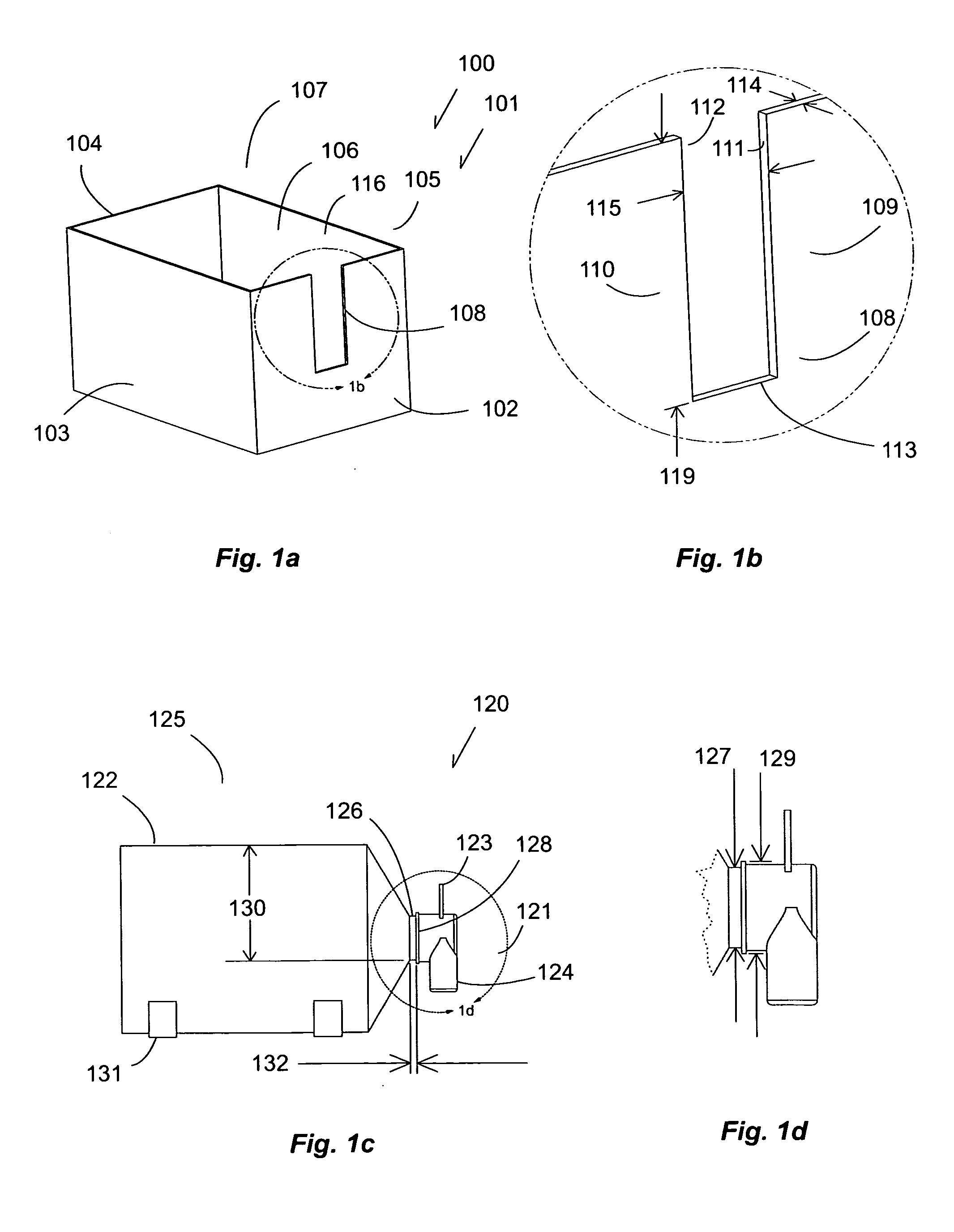

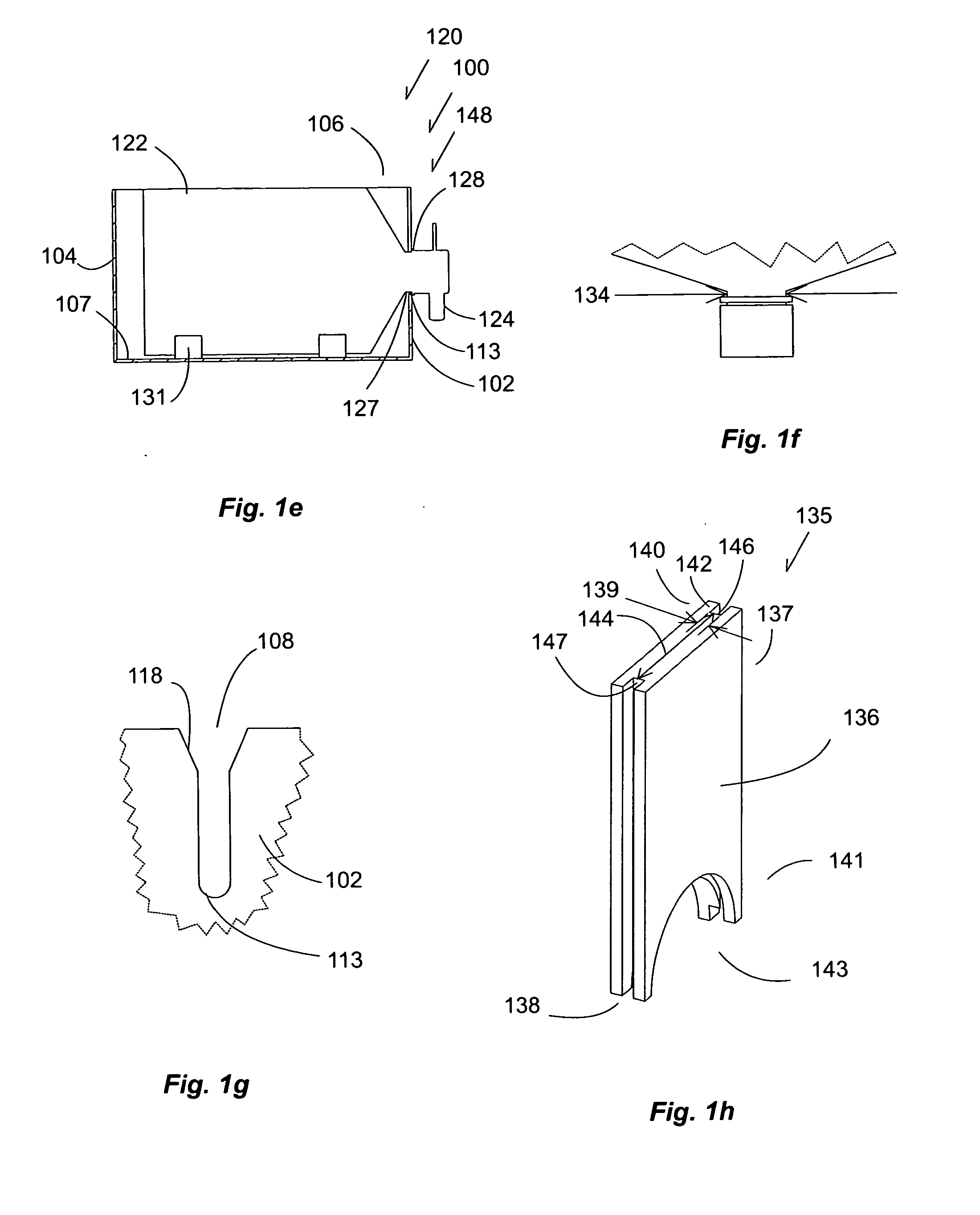

[0052]In this particular example, the first wall 102 includes a slot 108 extending from the inlet 116. The slot 108 includes a first engagement face 111 disposed on a first side 109, a second engagement face 112 disposed on a second side 110, and a stop 113 disposed between the first engagement face 111 and the second engagement face 112. In this particular example, the first wall 102 is of a thickness 114, and the slot 108 is of a width 115. In this first embodiment, the stop 113 is disposed a distance 119 from the inlet 116 of the chamber 106. The distance 119 represents a distance from a top edge of a product unit to a lowermost portion of a minor diameter of the product unit to ensure that a product vessel of the product unit is disposed within the chamber 106 when the minor diameter engages the stop 113.

[0053]In this first embodiment, the product unit 120 is a commonly available pressurized dispensing container, and is often utilized to dispense beer while sitting on a shelf in...

second embodiment

[0089]In an extension of the second embodiment, a container system 210 further includes a take-up hoop 236 for removing slack from the product vessel 222. The take-up hoop 236 includes a mounting face 237, and a cantilevered face 238 having a restraint slit 239. The cantilevered face 238, preferably is parallel to the floor of the chamber 206, and is disposed at an elevation near to the inlet 216 to lift any loose ends of the product vessel 222. The restraint slit 239 is of a width slightly larger than the thickness of four plys of the product vessel 222 material, such that the material that has been inserted through the restraint slit 239 does not easily come out of the restraint slit 239.

[0090]In this specific example, take-up hoop 236 includes mounting holes for securing the mounting face 237 to an inner wall of the chamber 206 with fasteners. On assembly, the mounting face 237 is positioned such that the cantilevered face 238 is disposed substantially parallel to the floor and a...

third embodiment

[0102]While this third embodiment has been shown with a product unit 320 that may be broken down to be sanitized, one of ordinary skill in the art will recognize that it is possible to permanently join a dispensing valve to the product vessel if the product vessel is formed from polyvinyl chloride or acetyl butyl styrene. In the case of a permanent joint, the sanitizing process would require the passage of detergents through the product path to sanitize the internal components.

[0103]While this third embodiment has been shown in a simplest form, one of ordinary skill in the art will recognize that all of the extensions of the first and second embodiments may be utilized in the third embodiment, and, therefore, should be considered to be part of the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com