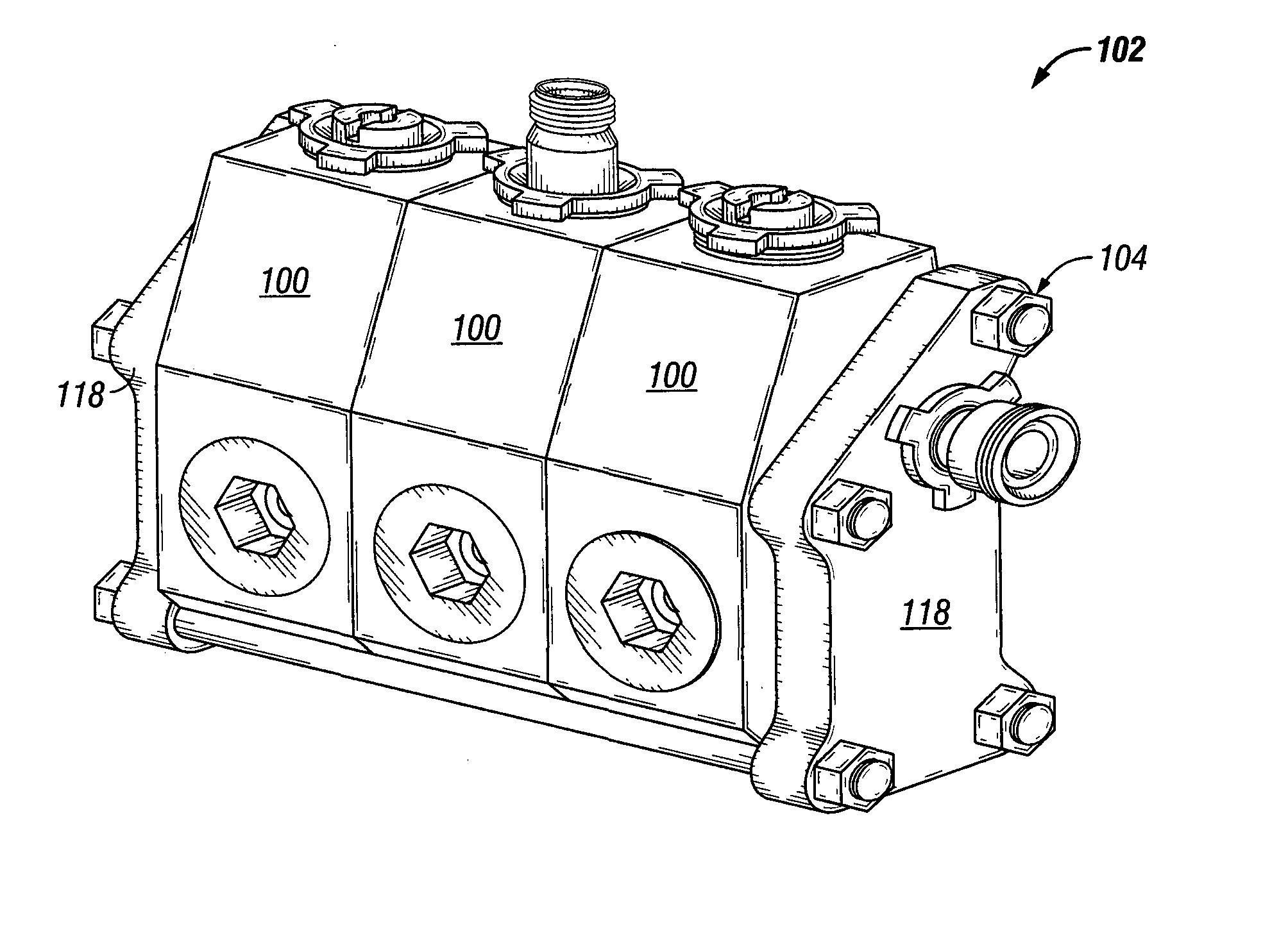

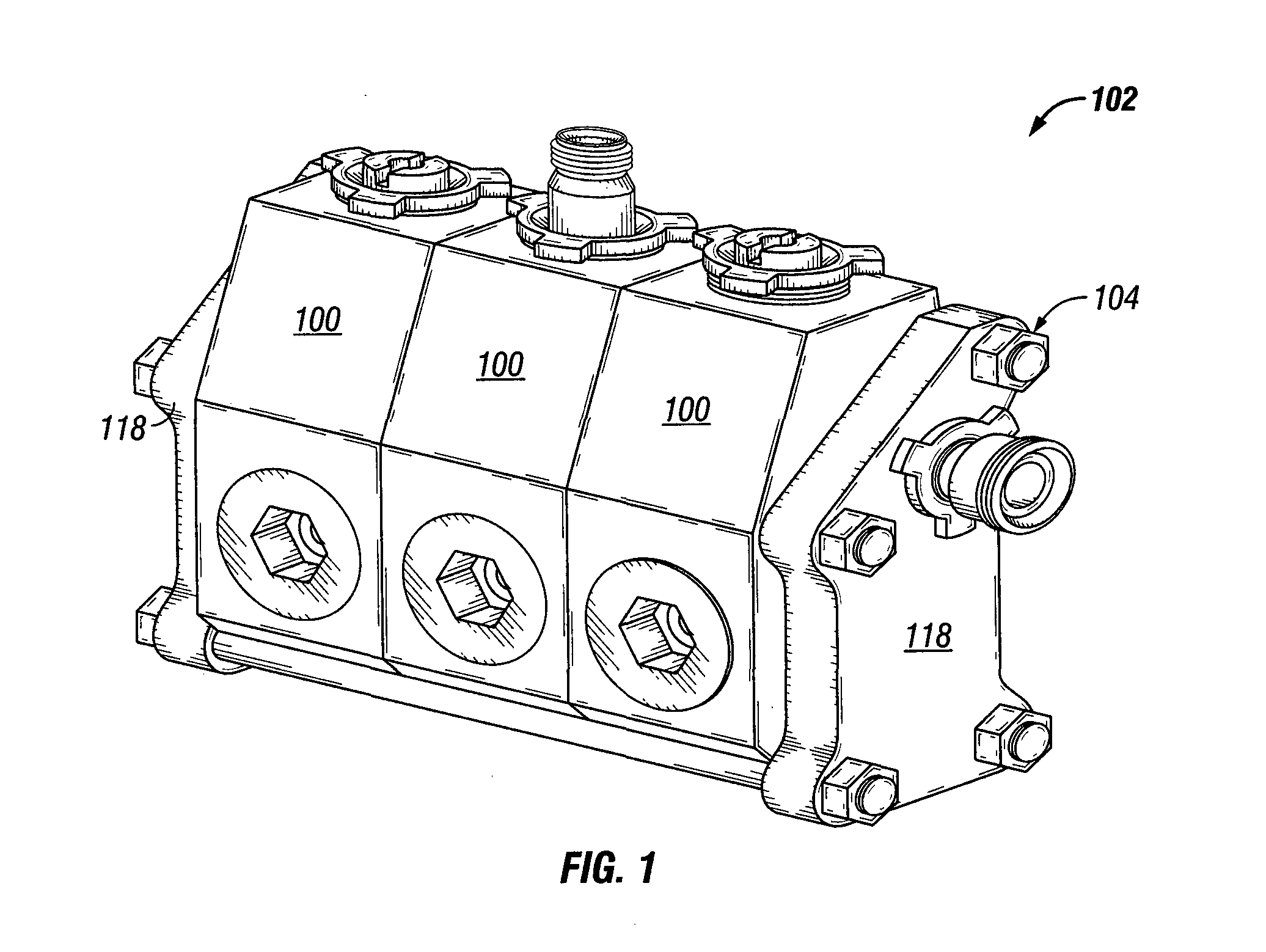

Fluid End Reinforced With Abrasive Resistant Insert, Coating Or Lining

a technology of inserts and abrasives, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of bore enlargement, two types of failures in the service life of fluid ends of reciprocating pumps,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The description and examples are presented solely for the purpose of illustrating the different embodiments and should not be construed as a limitation to the scope and applicability. While any compositions or structures may be described herein as comprising certain materials, it should be understood that the composition could optionally comprise two or more different materials. In addition, the composition or structure can also comprise some components other than the ones already cited. Although some of the following discussion emphasizes fracturing, the compositions and methods may be used in any well treatment in which diversion is needed. Examples include fracturing, acidizing, water control, chemical treatments, and wellbore fluid isolation and containment. Embodiments will be described in terms of treatment of vertical wells, but is equally applicable to wells of any well orientation. Embodiments will be described for hydrocarbon production wells, but it is to be underst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com