Carbon brush with disconnection apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

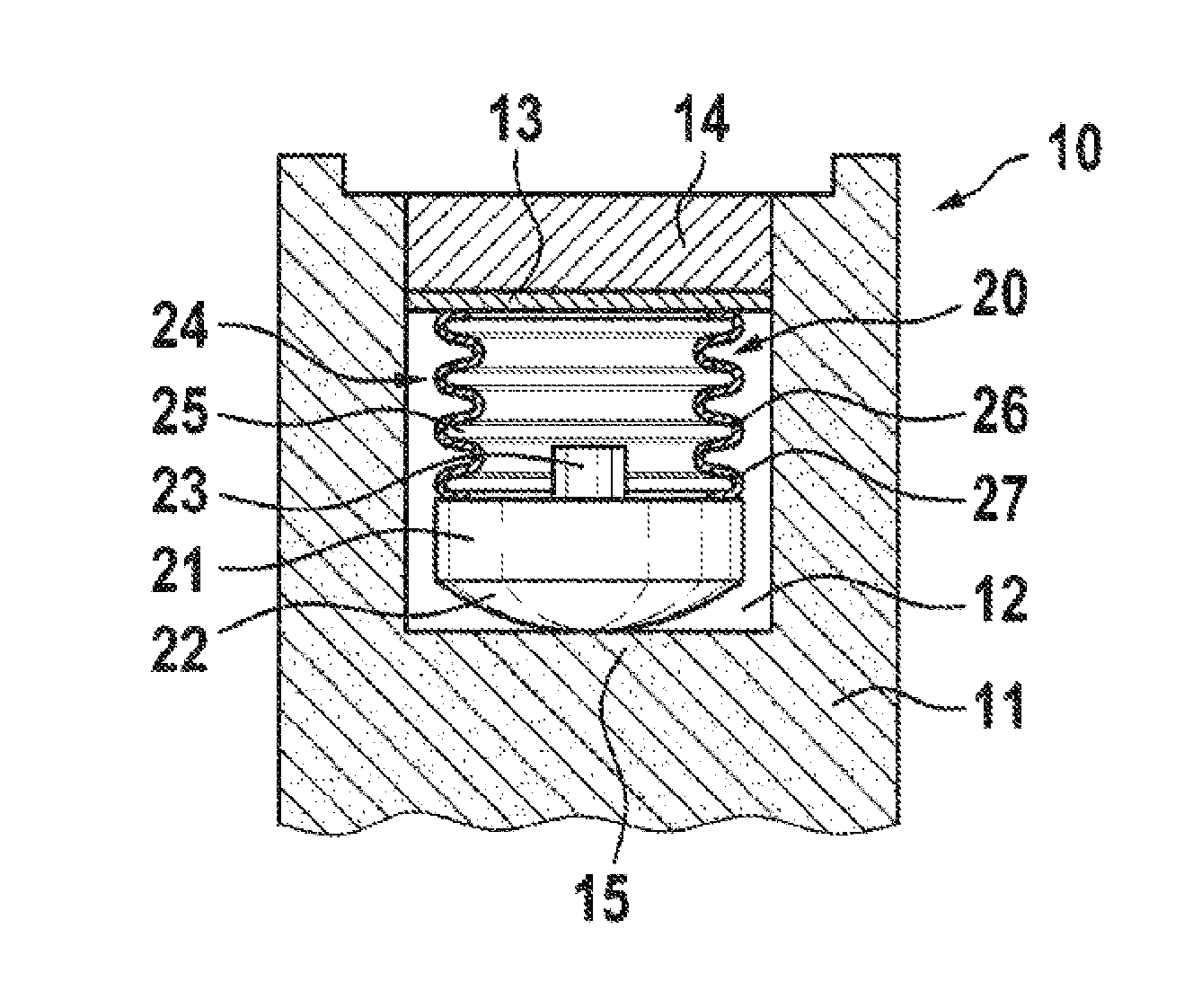

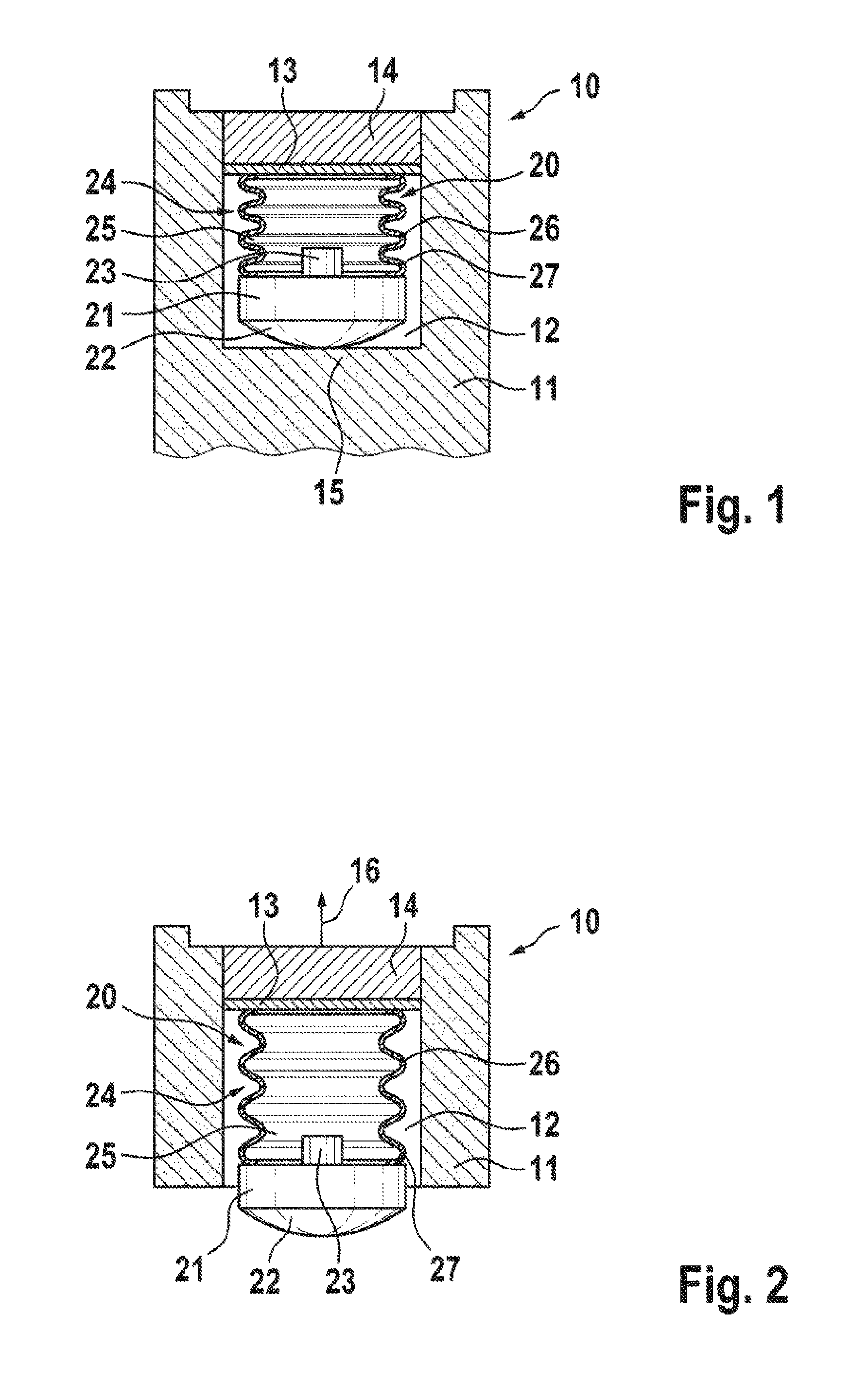

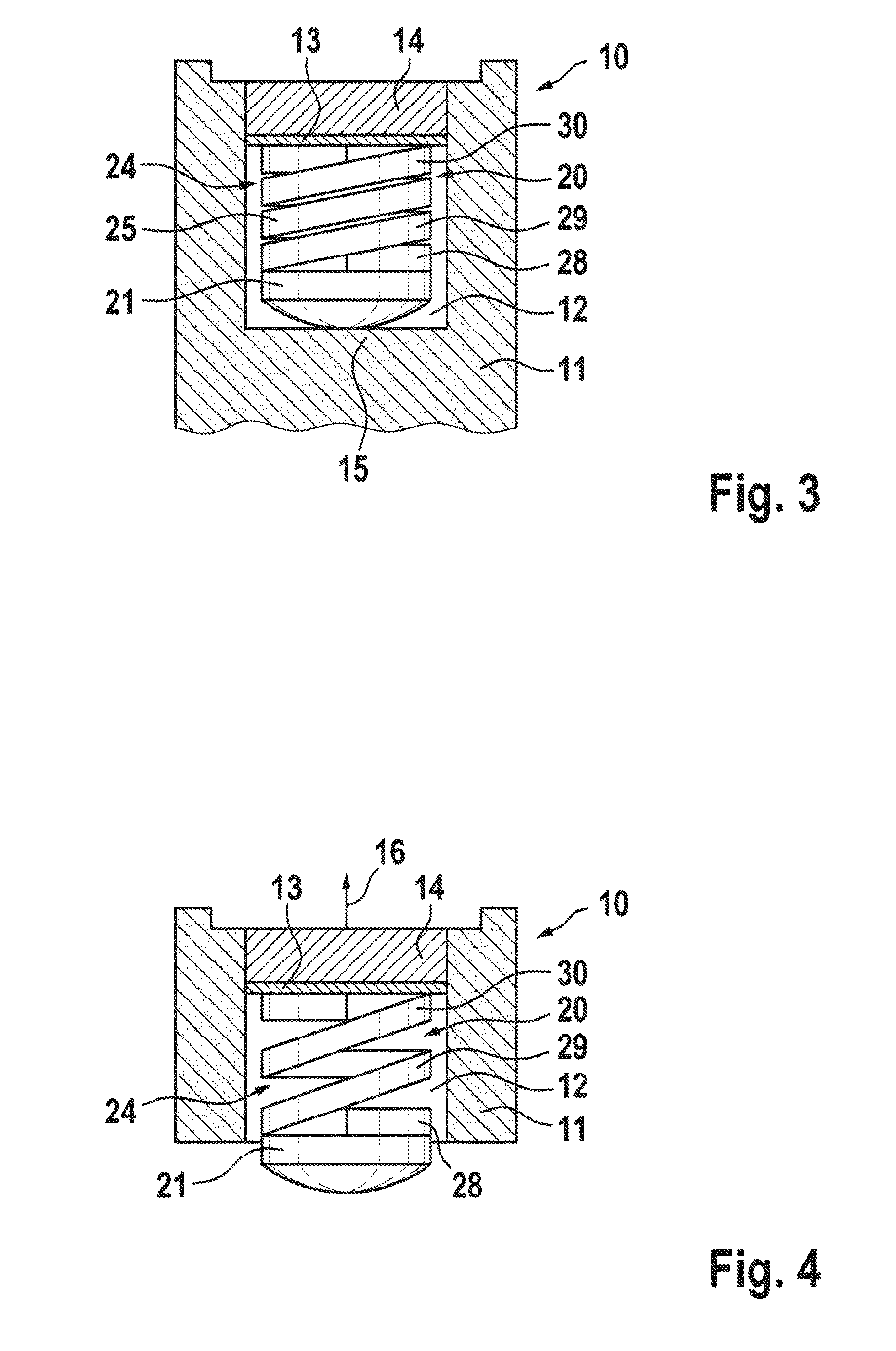

[0027]In the second exemplary embodiment, shown in FIGS. 3 and 4, the compression-spring body 24 is once more made of plastic and springy. It can be formed of a thermoplastic. The compression-spring body 24 is formed as an approximately cylindrical helical spring 25 having a plurality of spring turns 28, 29, 30, the spring turns running spirally. Instead of this, the compression-spring body 24 according to FIGS. 3 and 4 can also have such spring turns which, at least in the preloaded, compressed state, are located at least partly one inside the other, when shortening the compression-spring body 24. Illustrated in FIGS. 3 and 4 at the upper end of the cavity 12 is a separating disk 13, which is necessary when the spring 25 is not able to seal the cavity 12 against the material of the plug 14 on the basis of its material-based sealing capacity. The compression-spring body 24 and the disconnection body 21 are combined to form an integral one-piece plastic component and thus constitute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com