Hinge Lid Package

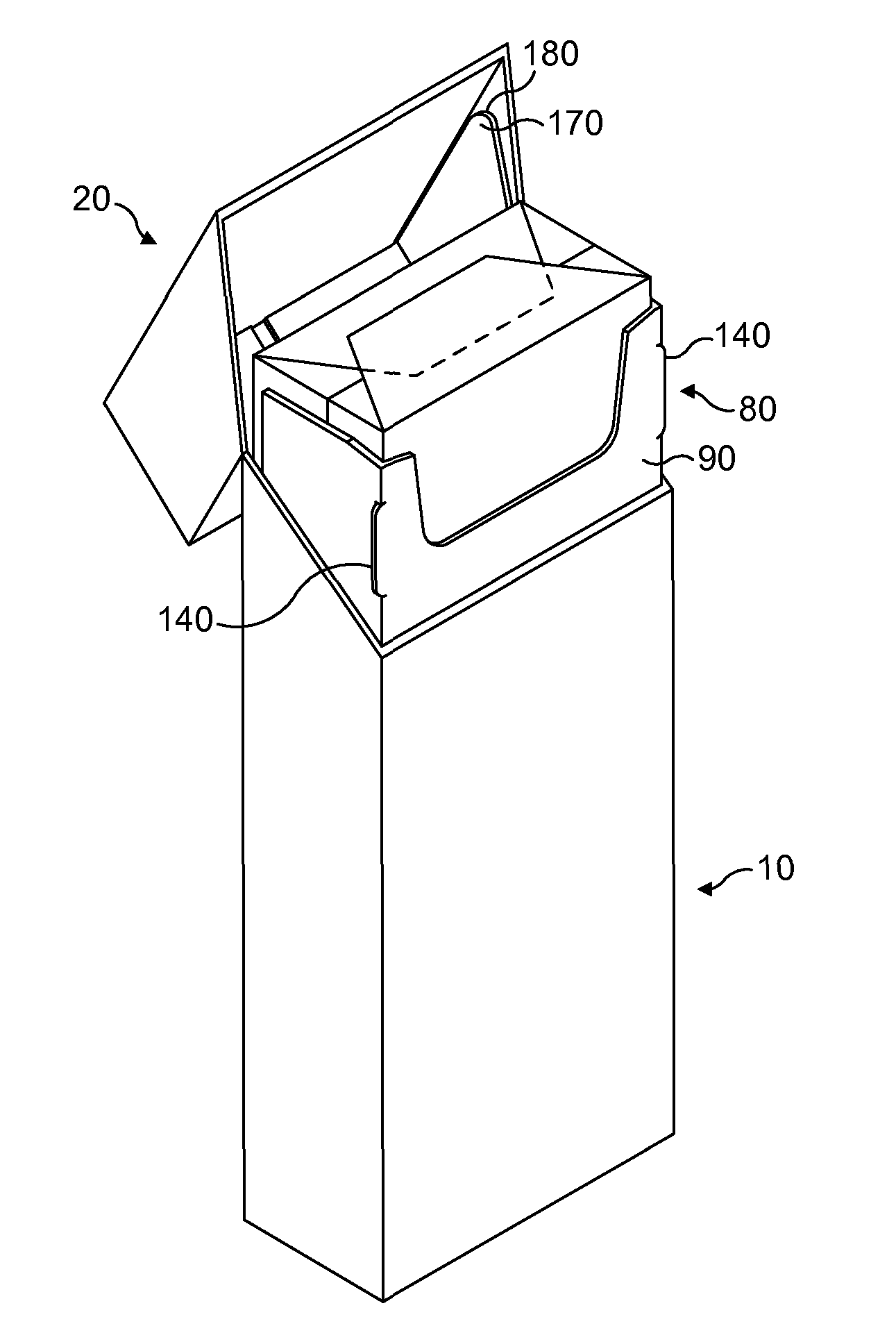

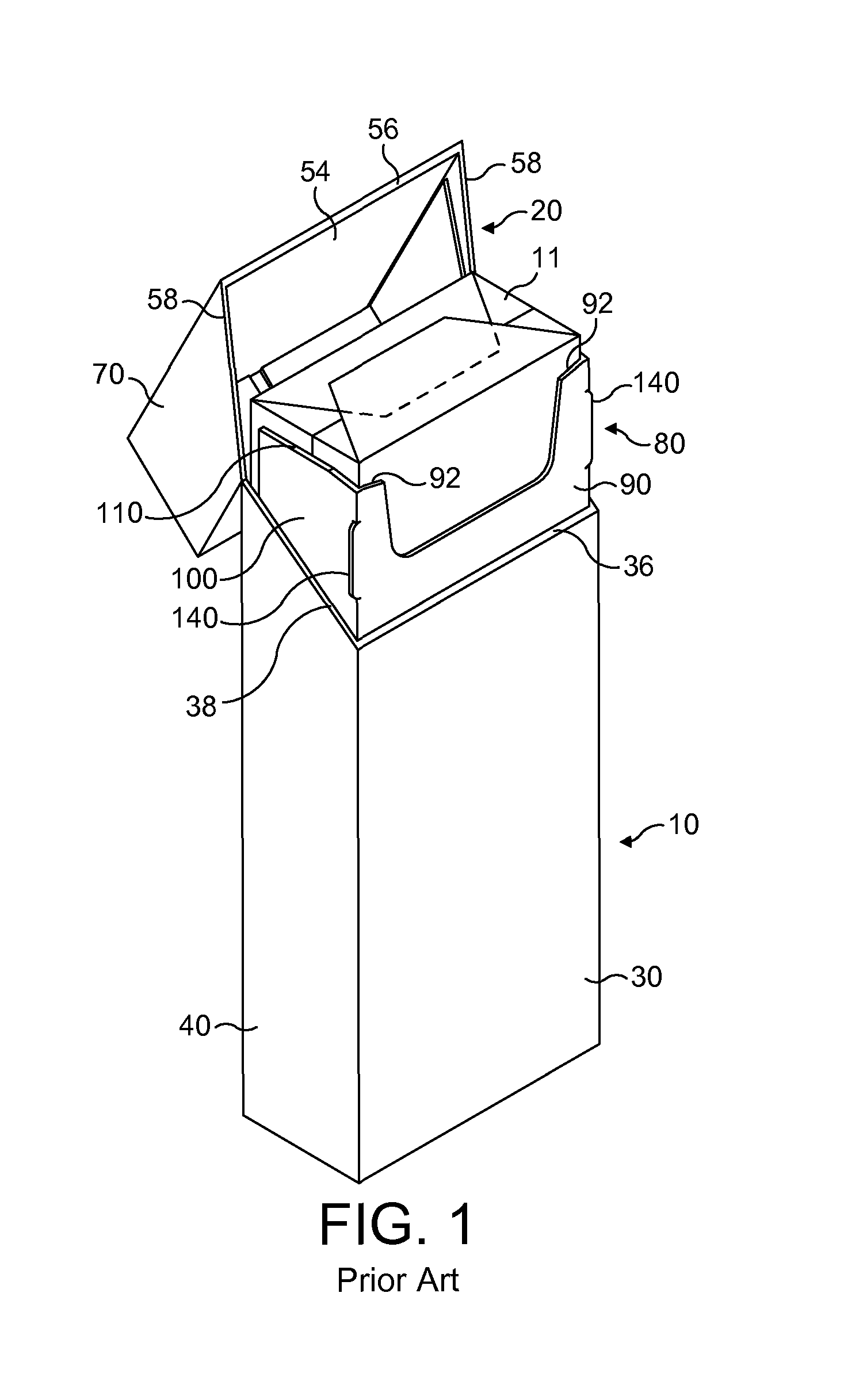

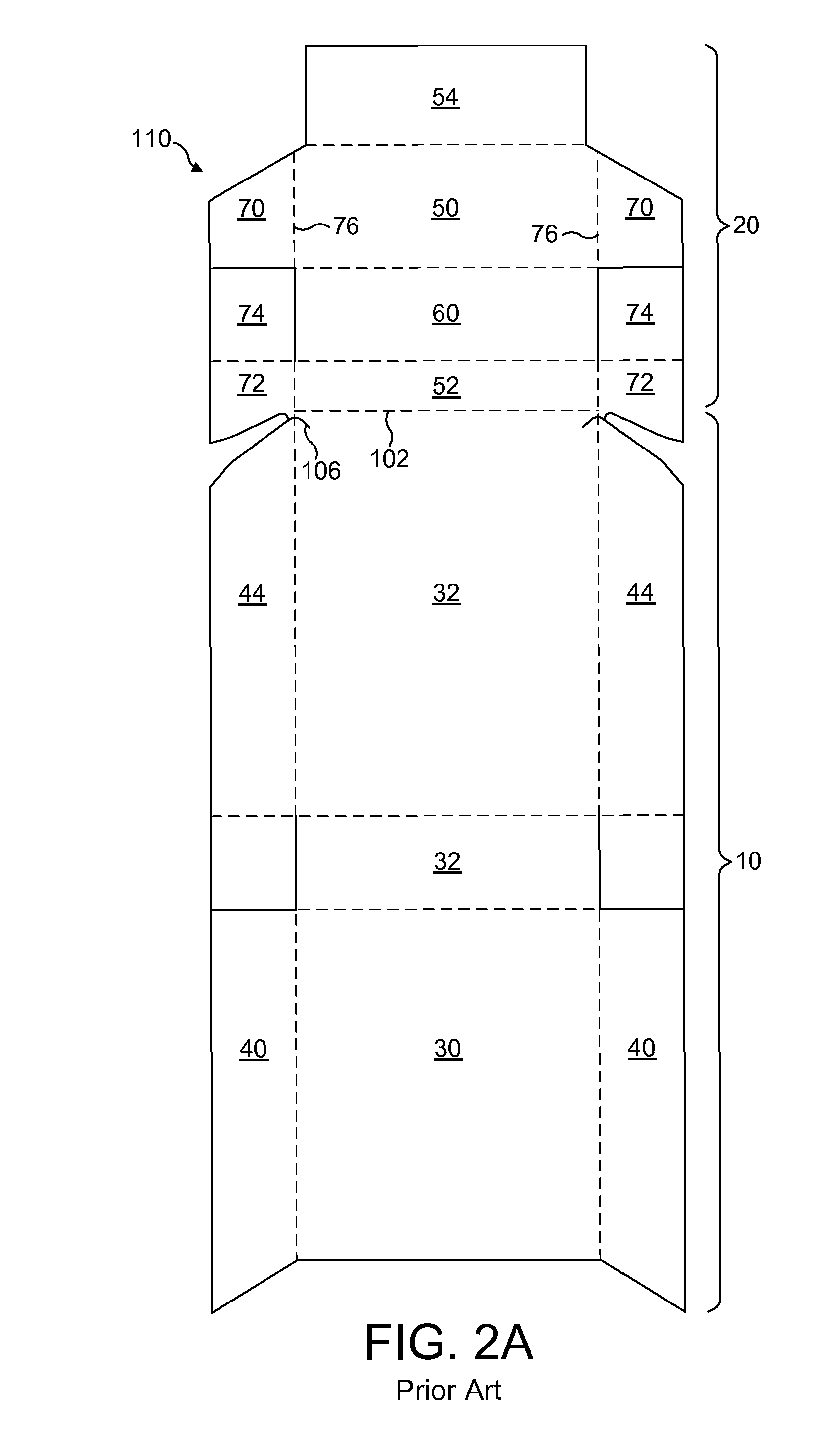

a lid package and lid technology, applied in the direction of packaging goods, tobacco, liquid handling, etc., can solve the problems of package damage, package damage, and difficult opening and closing of packages, so as to prevent the occurrence of package “smiling”, improve the opening and closing mechanism, and less force to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Package “Smiling”

[0151]The following test was designed in order to test the occurrences of package “smiling”. Measurements of the degree of smiling were completed on cigarette packages according to the present invention, including packages comprising: (i) a cam panel only; (ii) a cam panel and improved latching tab only; and (iii) a cam panel, improved latching tab, improved inner frame and a raised pivot axis. Conventional cigarette packages currently on the market, which did not contain any of the four improvements described herein, served as controls.

[0152]Each package was dropped from an elevation of 10 cm six times, and the degree of smiling measured with a ruler. In each case the package was dropped so that it would land with its back panel 32 facing downwards. The gap or opening between the bottom edge 56 of the lid front panel 50 and the top edge 36 of the box front panel 30 was considered to be the smile, as illustrated in FIG. 32B. Following the initial drop and after each...

example 2

Required Package Opening Force

[0155]The following test was used to determine the degree of opening force required to open a cigarette package. Again, measurements of the degree of force required to open a package were completed on cigarette packages according to the present invention, including packages comprising: (i) a cam panel only; (ii) a cam panel and improved latching tab only; and (iii) a cam panel, improved latching tab, improved inner frame and a raised pivot axis. Conventional cigarette packages currently on the market, which did not contain any of the four improvements described herein, served as controls. The force required to open a package was measured a total of six times for each package using a conventional Packaging corporation of America (PCA) score bend tester as illustrated in FIG. 33(A-C).

[0156]Briefly, packages were placed in a holder so that box part 10 was immobile, and lid 20 was clamped either on one side (as in most tests) or in the middle (FIG. 33A). Th...

example 3

Latching Tab Configurations

[0158]The following inner frame and package blank new profiles were tested in different combinations on a Focke 350S high-speed hinge lid packer:

Controls:

[0159]a standard inner frame profile (STD)

[0160]a standard box part blank (STD)

Test Materials:

[0161](As depicted in FIG. 36)[0162]Inner frame “A” with front top corners cut-off and a latching tab profile “A”[0163]Inner frame “B” with front top corners cut-off and a latching tab profile “B”[0164]Inner frame “C” with front top corners cut-off and a latching tab profile “C”[0165]Inner frame “D” with front top corners cut-off and a latching tab profile “D”[0166]Inner frame “E” with front top corners cut-off and a latching tab profile “E”[0167]Package blank 1, having raised pivot axis, standard inner frame, standard latching tab, no cam panel[0168]Package blank 2, having raised pivot axis, standard inner frame, standard latching tab, lid inside panel have a non-engaging curved profile.

[0169]The results, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com