Heat exchanger and air conditioner equipped with same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]With reference to the appended drawings, the following describes embodiments of the present invention.

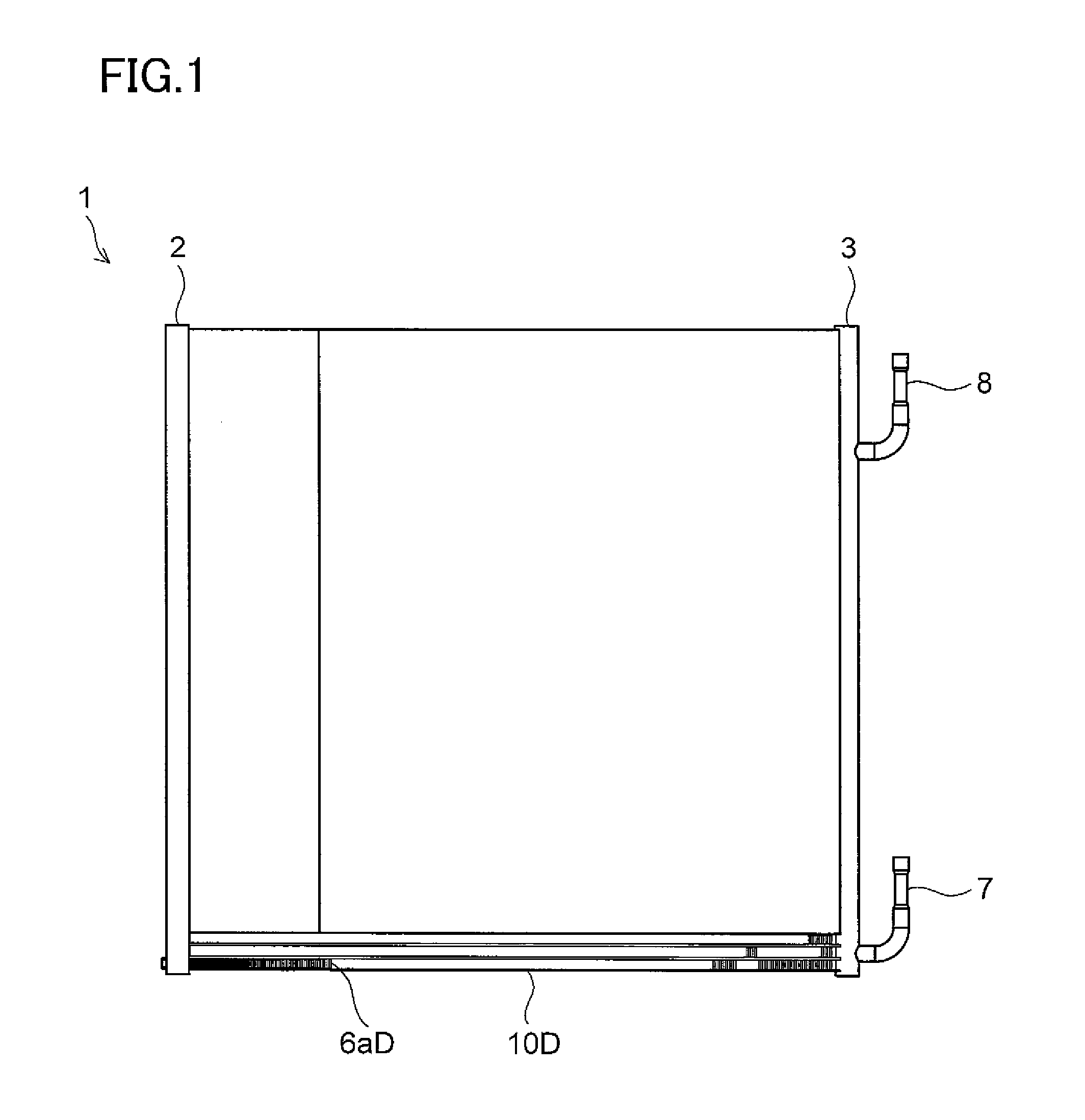

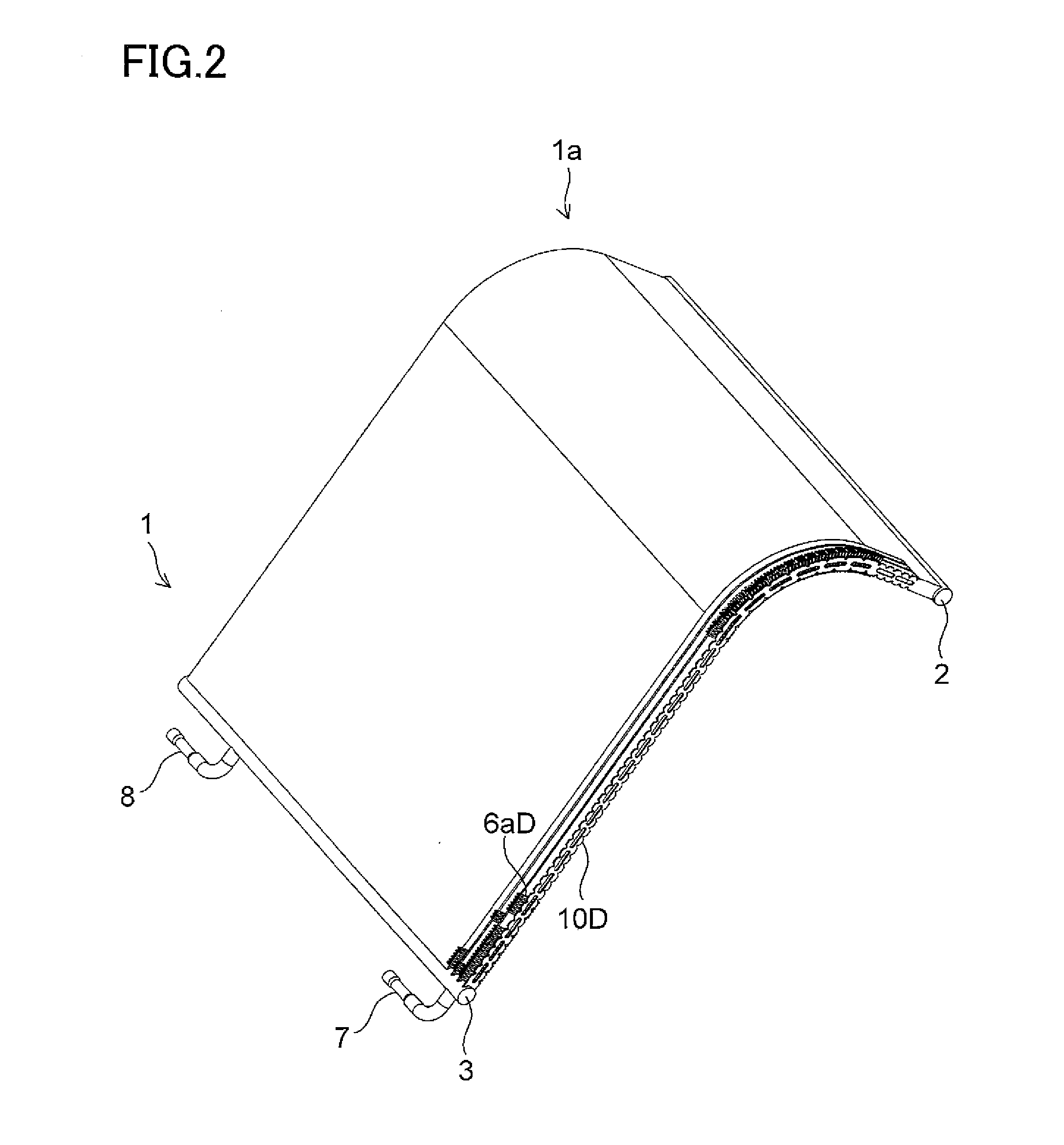

[0055]FIGS. 22 and 23 show a basic structure of a side-flow type parallel-flow heat exchanger. In each of FIGS. 22 and 23, an upper side of the figure is an upper side of the heat exchanger, and a lower side of the figure is a lower side of the heat exchanger. In a heat exchanger 1, two perpendicular header pipes 2 and 3 are arranged parallel to each other at an interval therebetween in a horizontal direction, and between the header pipes 2 and 3, a plurality of horizontal flat tubes 4 are arranged at a predetermined pitch in a perpendicular direction. Each of the flat tubes 4 is an elongated metal member formed by extrusion and has therein a refrigerant passage 5 for a refrigerant to flow therethrough. The flat tubes 4 are arranged with an extrusion direction thereof, which is also a longitudinal direction thereof, set to be horizontal, and thus a direction in which a refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com