Articulated mannequin with various assembly mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

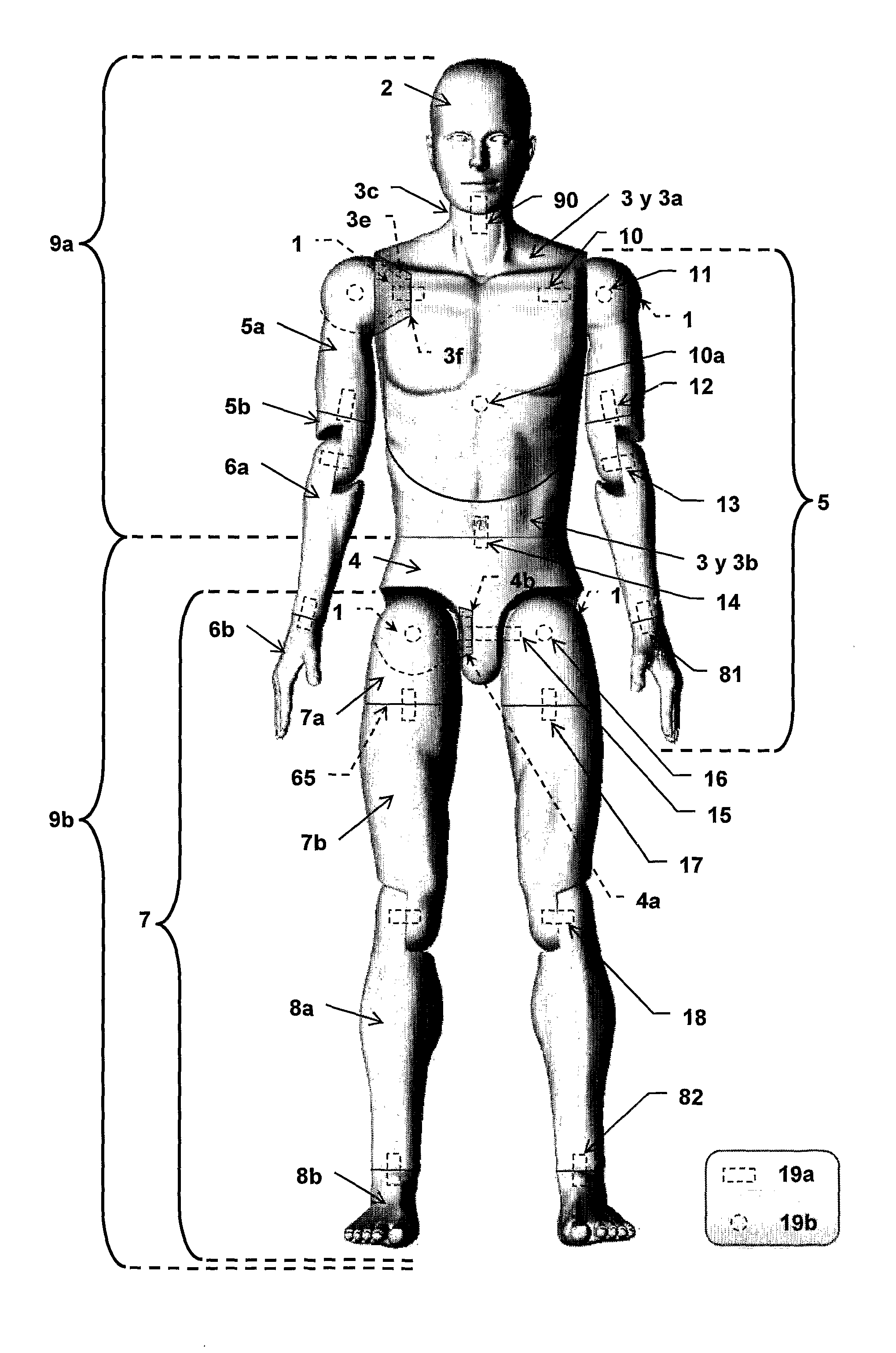

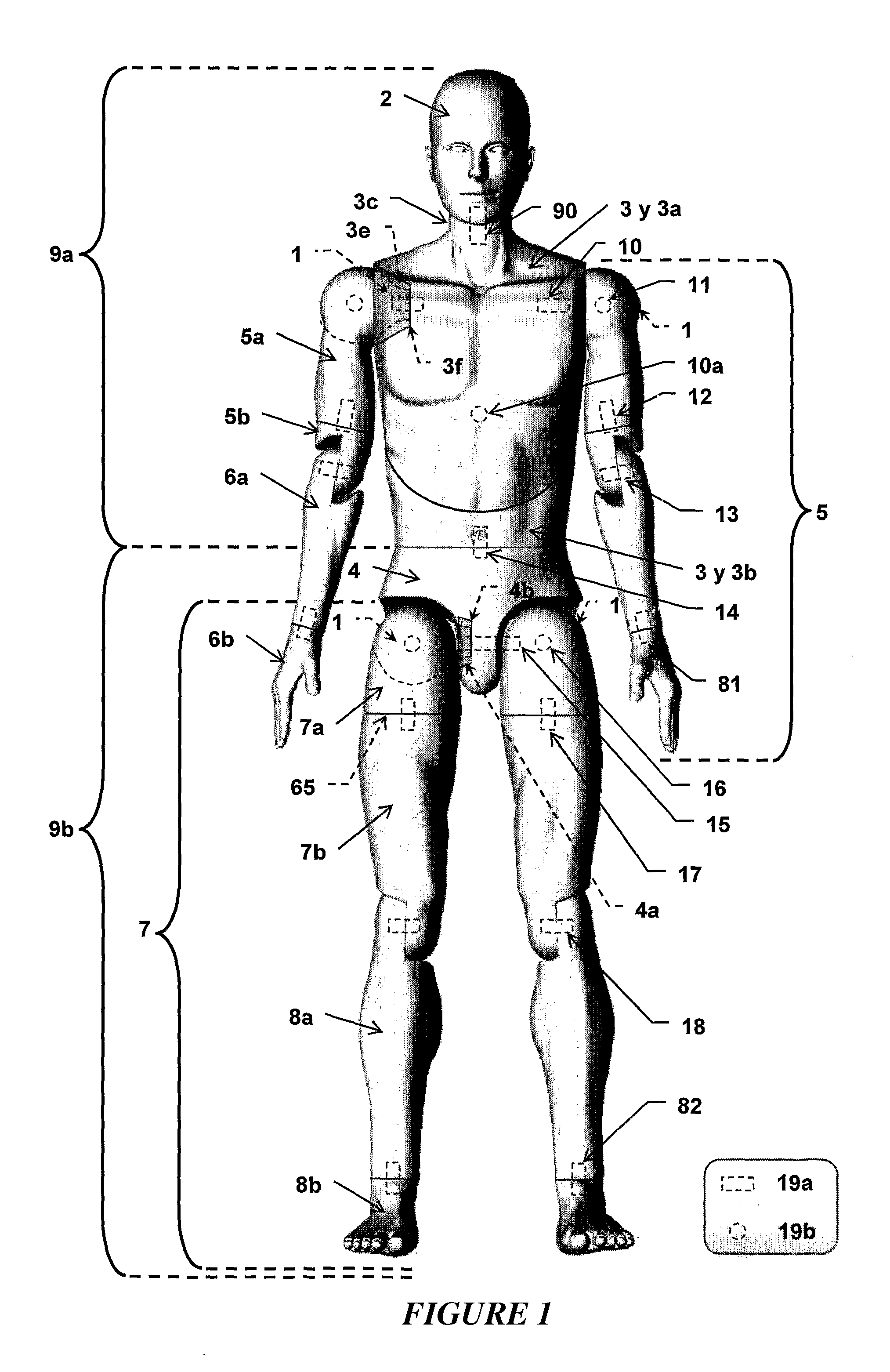

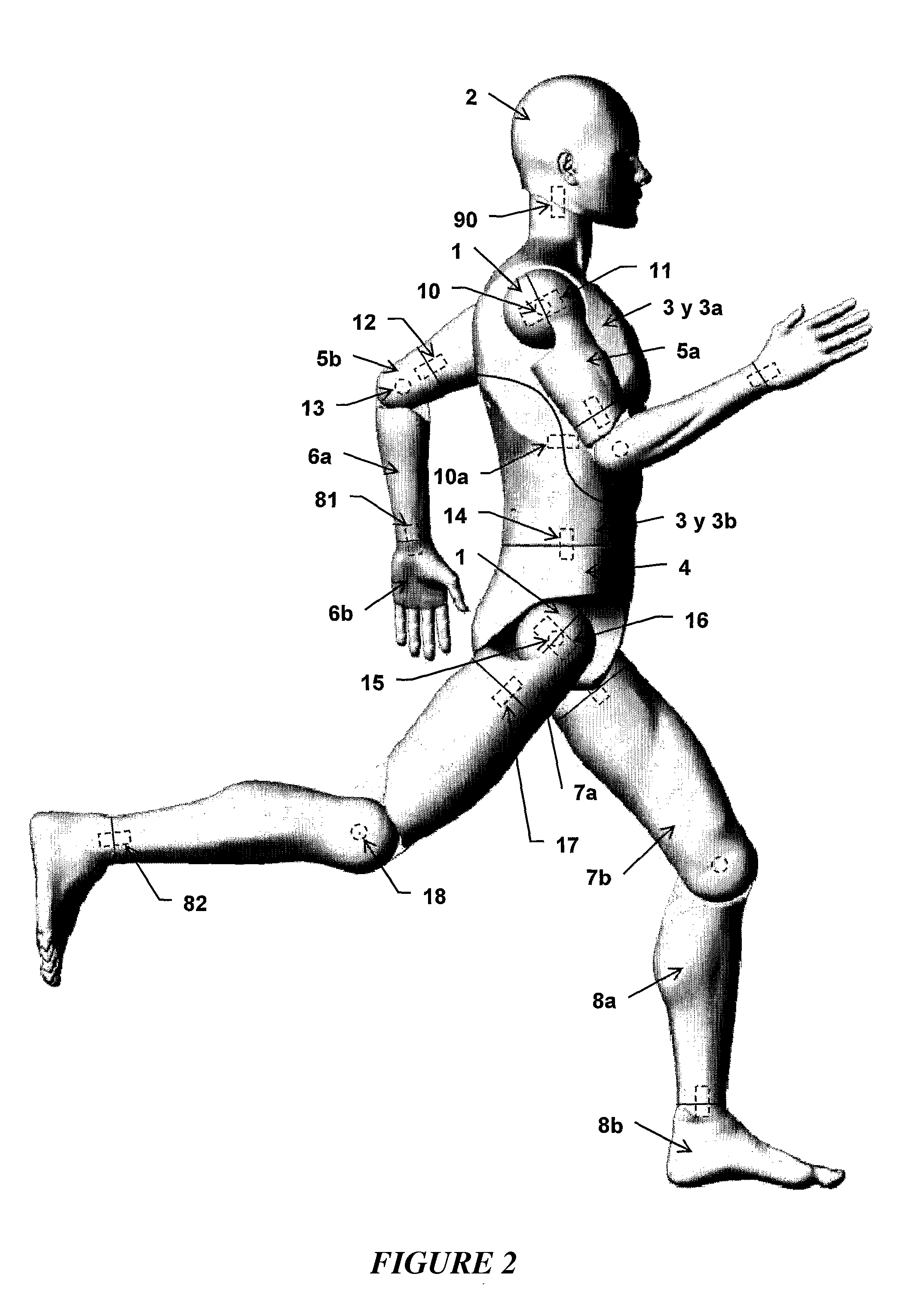

[0016]The present invention is related to various assembly mechanisms that can be installed in the actual articulated mannequin, wherein said invention is mainly related with a human appearance, capable of optimizing the use efficiency.

[0017]The characteristic details and methods for installing, assembling, adjusting and manipulating the various members and assembly mechanisms of the present articulated mannequin, are explained in the following description and are shown in the accompanying figures, which are mentioned by way of example and not to be considered as limiting the present invention.

[0018]The assembly mechanisms embedded in the various members of the articulated mannequin, are characteristics that result in greater benefits in their applications, thus facilitating the dressing and undressing manipulations of the articulated mannequin as well as ease of handling, based on the simplicity with which said articulated mannequin can be adjusted to adopt various postures; beside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com