Method and Apparatus for Corrosion Allowance Mitigation

a technology of corrosion allowance and corrosion allowance, applied in the design of tanks, vessels, hull parts, etc., can solve the problems of increasing weight, stiffening, and structural elements such that they are no longer industry standard items, and achieve the effect of reducing the amount of structural materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

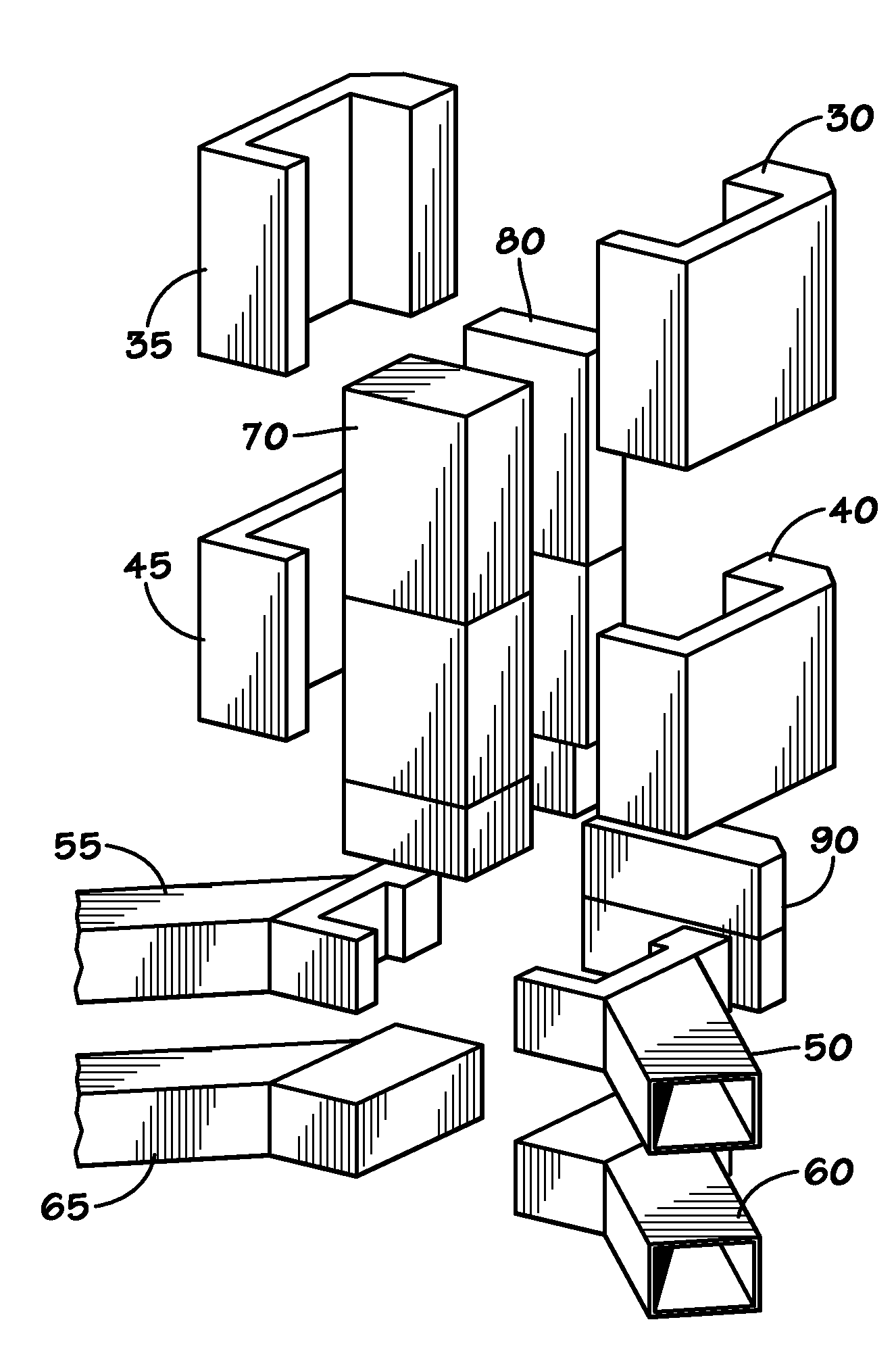

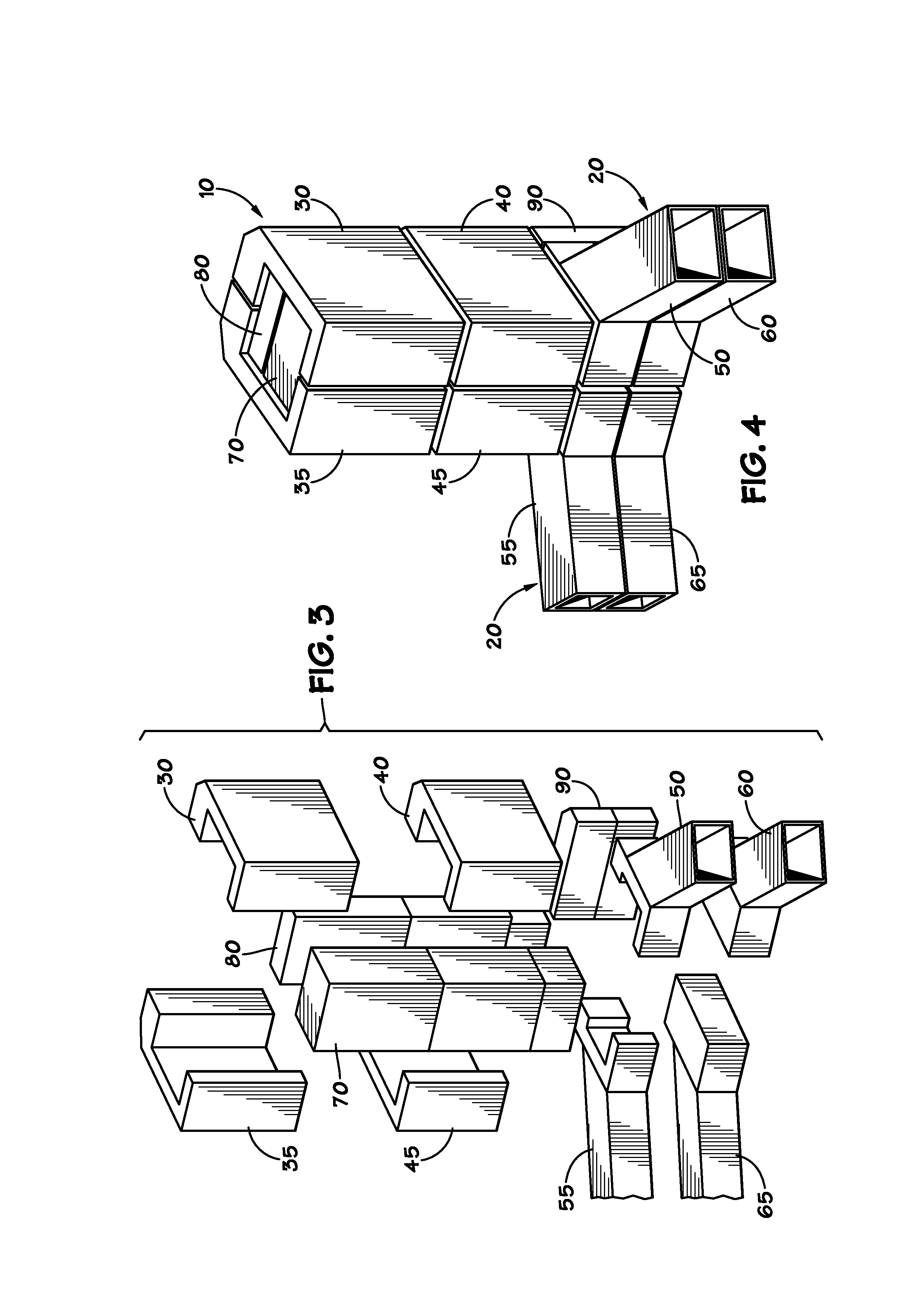

[0018]The invention may best be understood by reference to the exemplary embodiment(s) illustrated in the drawing figures.

[0019]An important advantage of the method of the invention is that hull structural weight can be reduced by mounting the stiffeners, bulkheads, girders, etc. on the dry side of the structural element as opposed to the wet side, where they are exposed to ballast water—typically, chemically-treated seawater. The design is such that the “dry” corrosion allowance can be applied to a large percentage of the steel comprising the ballast tank scantlings, rather than the much greater “wet” corrosion allowance.

[0020]Another advantage of the method is that the stiffeners and girders and many gussets may be absent from the ballast tank internal surfaces, where typically sophisticated and expensive corrosion resistant coatings must be applied. The method thus not only reduces the total surface area to be painted, but sharp corners, rat-holes, cutouts and other structural di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com