Rotor blade for a wind turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

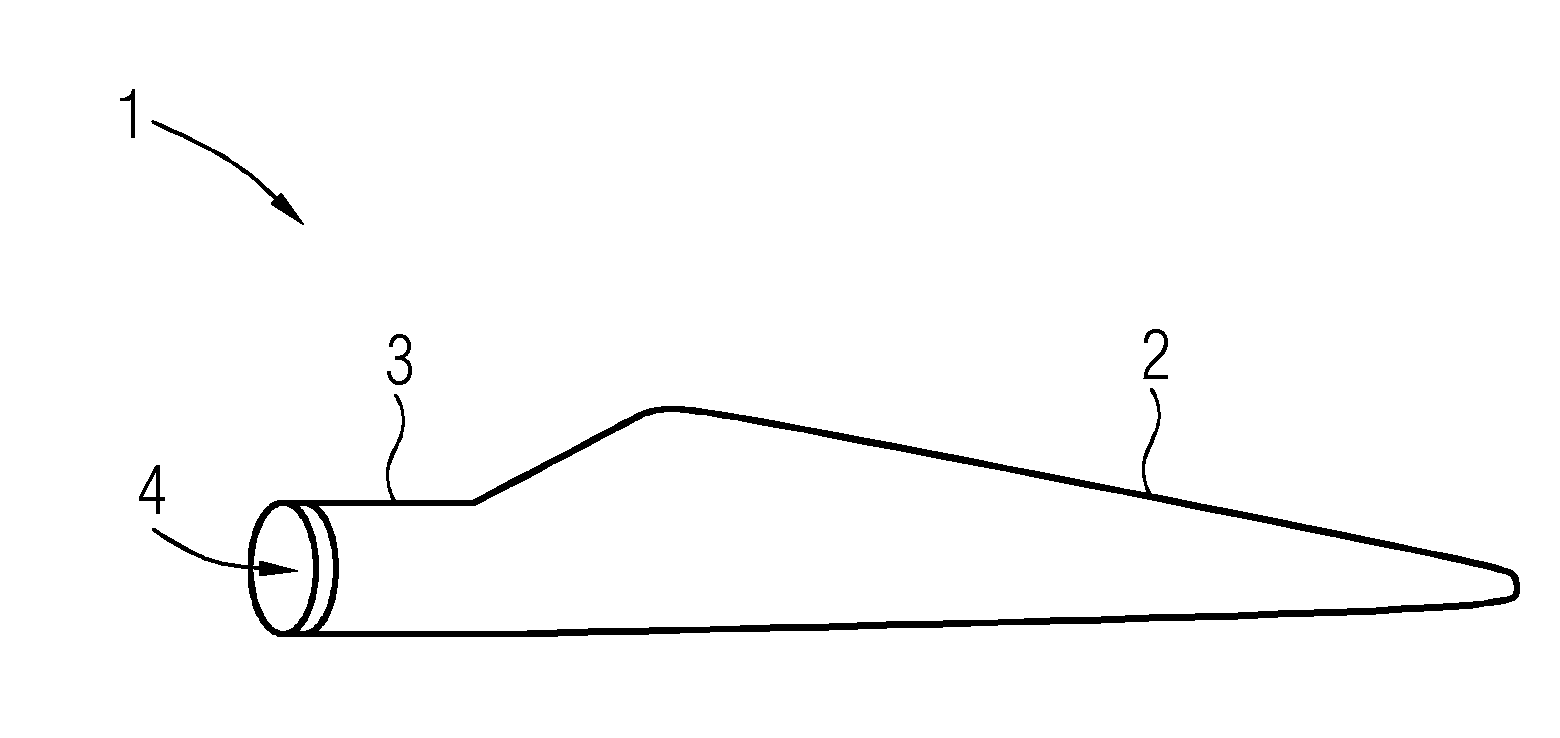

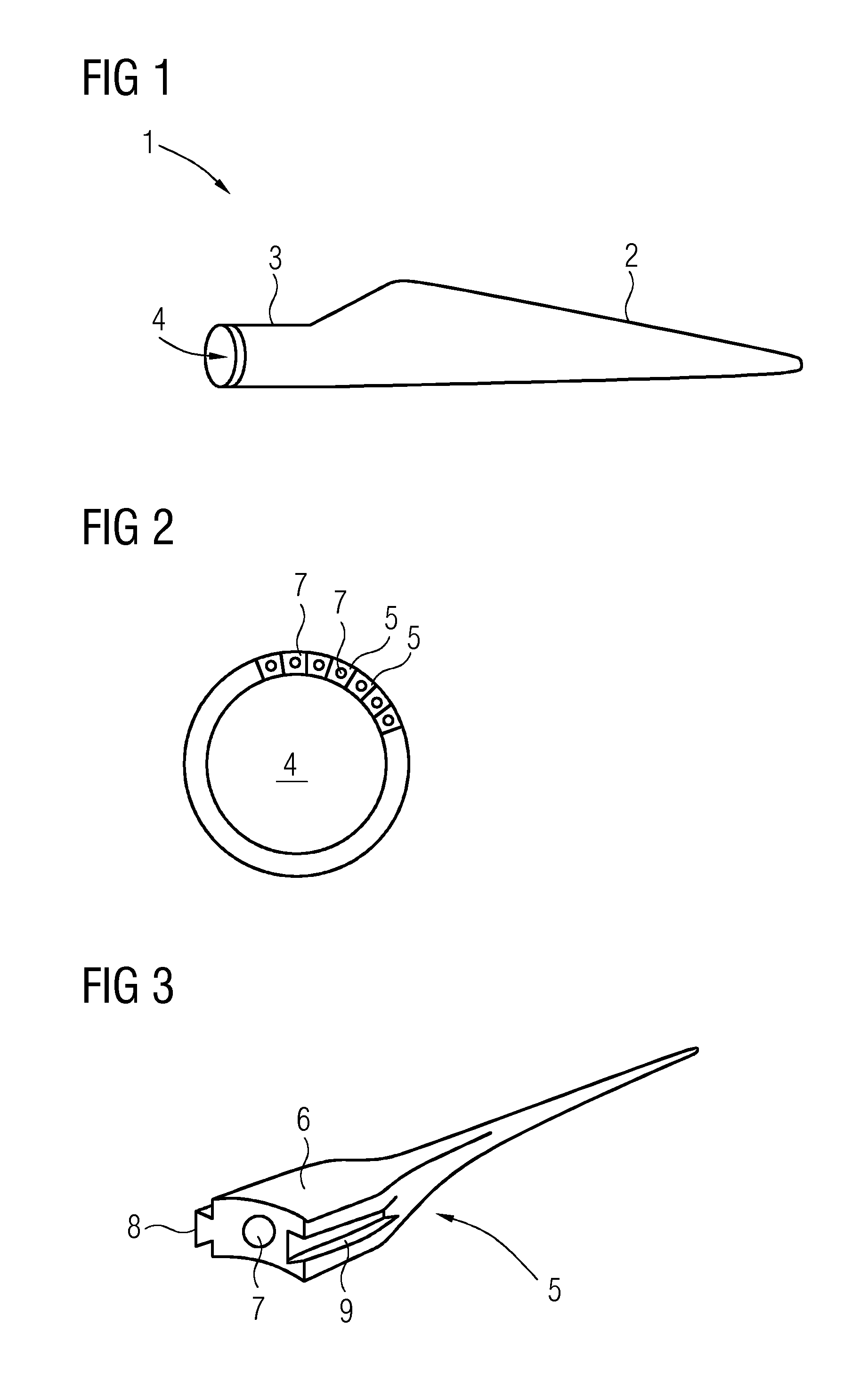

[0025]FIG. 1 shows a principle view of a rotor blade 1 according to an exemplary embodiment of the invention. The rotor blade 1 comprises an elongate base body 2 which axially ends in a respective blade root 3 having a respective circular root face side 4 (cf. FIG. 2). The rotor blade 1 is a hollow component made of a fibre-reinforced resin or cast material. The rotor blade 1 is attachable to a rotor hub of a wind turbine, particularly a direct drive wind turbine (not shown).

[0026]As is shown in FIG. 2, the face side 4 of the blade root 3 has a ring-like shape, whereby respective connecting elements 5 (cf. FIG. 3) are connected in circumferential direction so as to build a circumferentially closed ring-shape.

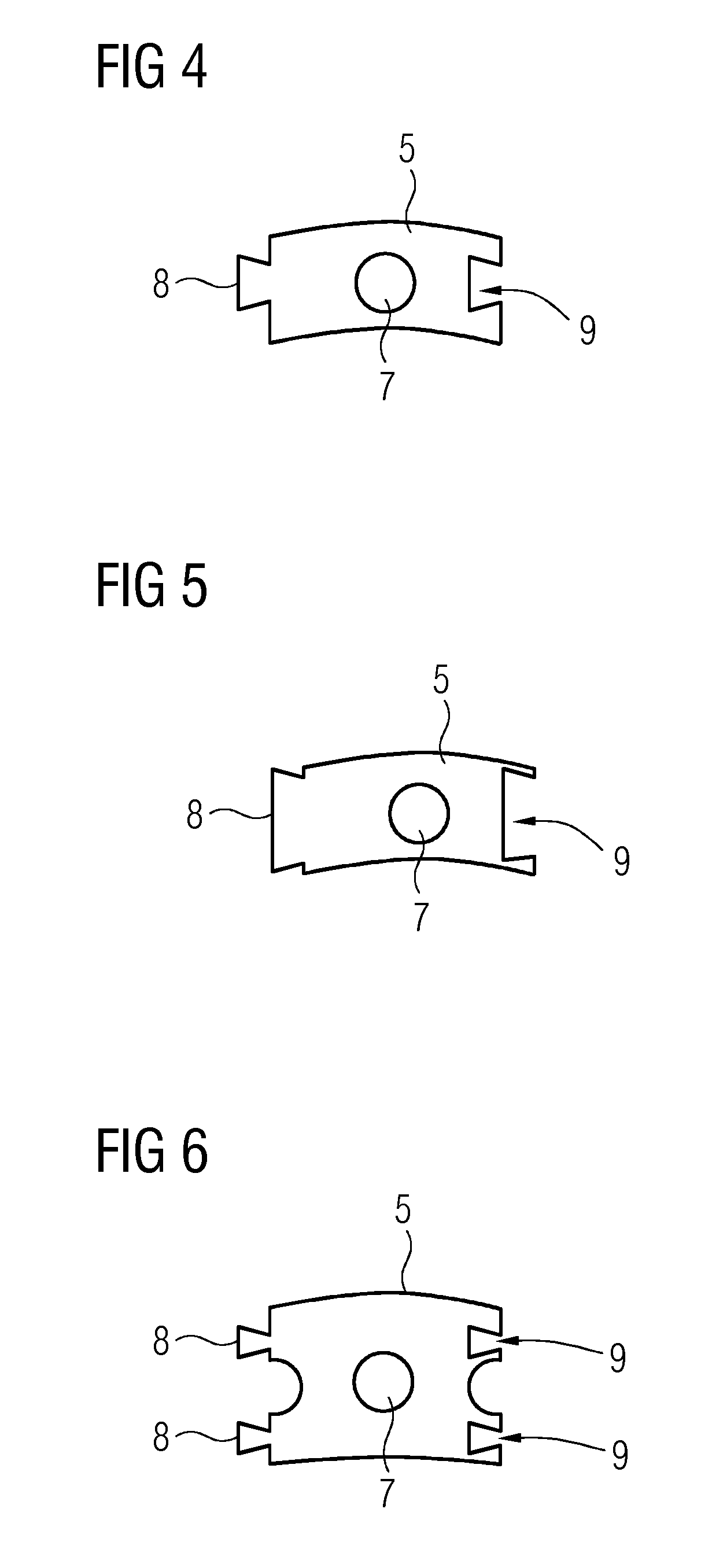

[0027]The connecting elements 5, which may also be denoted as studs, are shown in FIG. 3. A respective connecting element 5 comprises an axially extending base body 6 having an axially extending connecting portion 7 in the shape of a threaded hole. The axially extending connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com