Burner for Particulate Fuel

a technology of particulate fuel and burner, which is applied in the direction of burners, combustion types, pulverizing fuel combustion burners, etc., can solve the problems of high degree of turbulence and coal particle concentration, high degree of wear of biomass equipment, and high degree of coarseness of biomass, so as to reduce the swirl, intensify the swirl of primary air flow in regions, and reduce the swirl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

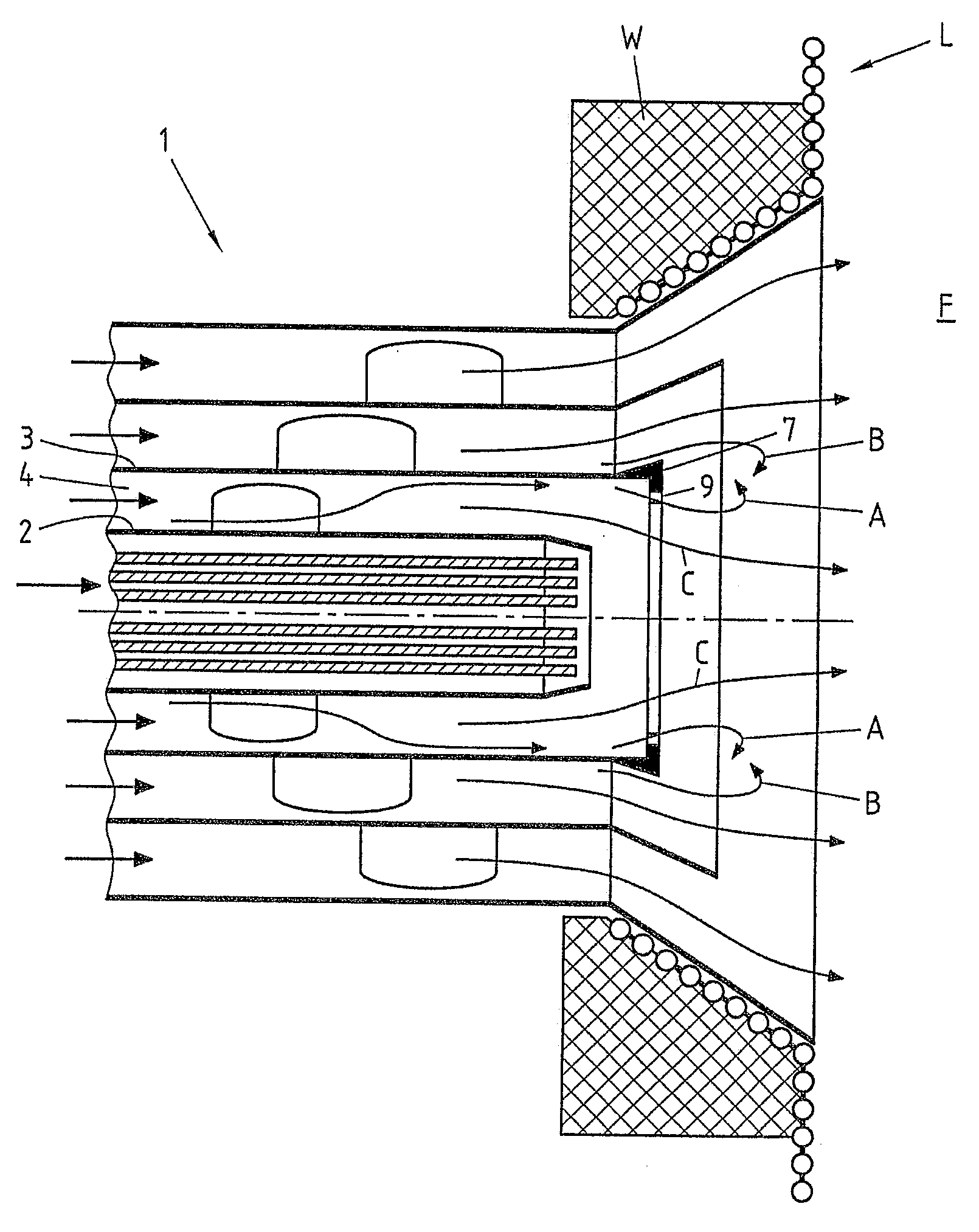

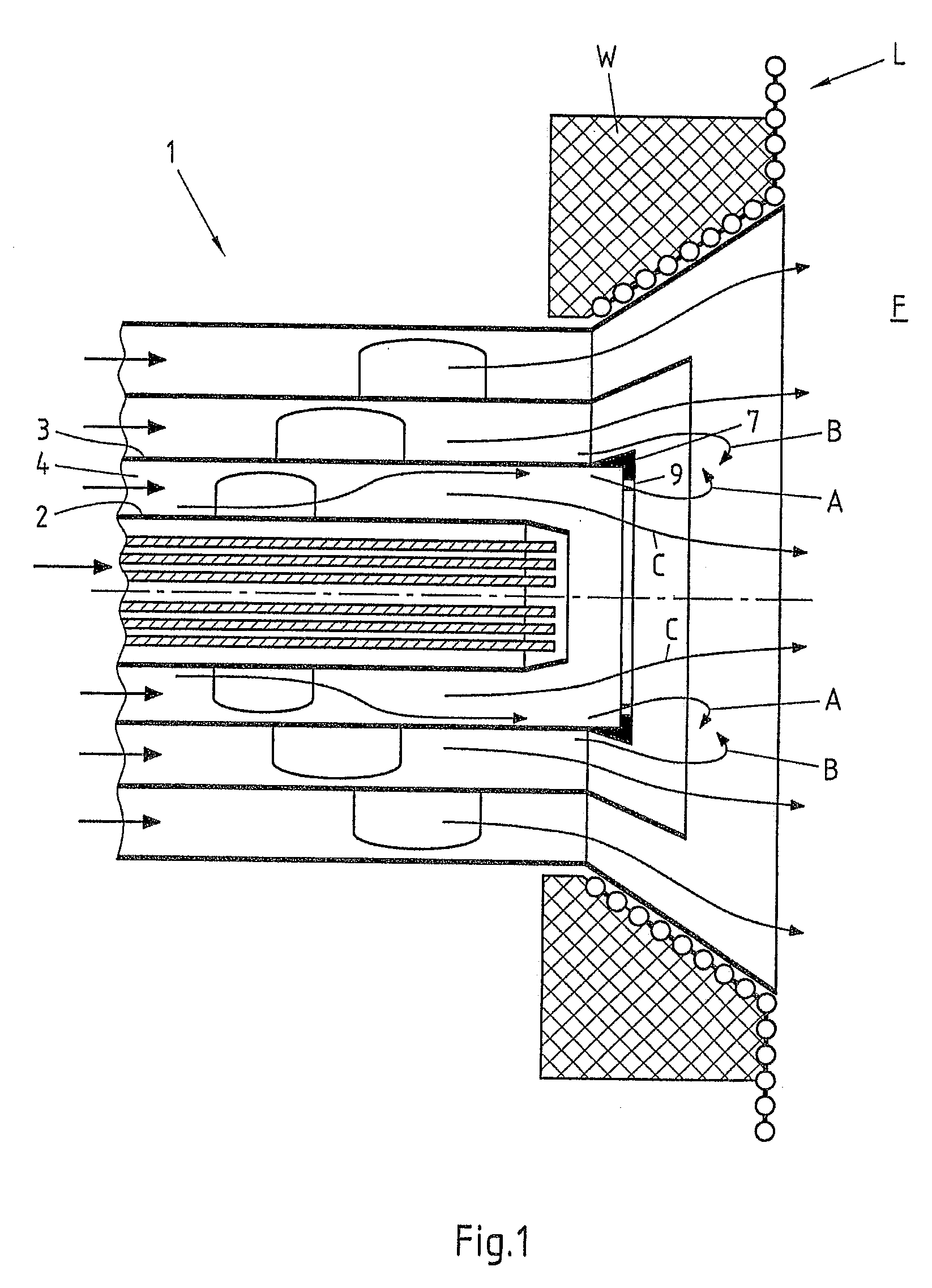

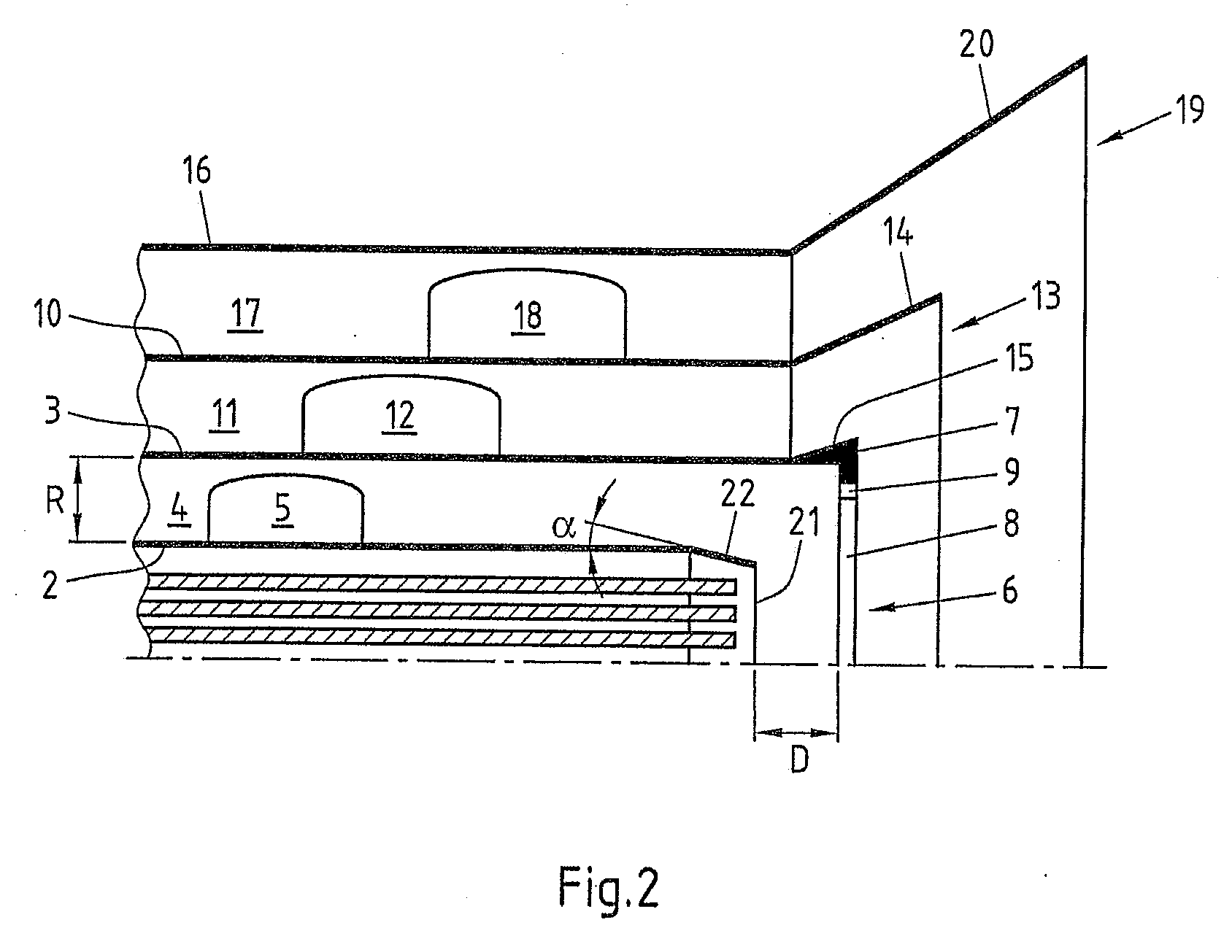

[0039]FIG. 1 shows a longitudinal section through a burner 1, which is arranged in a wall W of a combustion chamber F. The inner part of the burner 1 from FIG. 1 is shown to an enlarged scale in FIG. 2 for improved clarity.

[0040]A core tube 2, in which a burner gun, not shown, can be provided, is provided in the centre of the burner 1. Other devices are also possible, which are shown here purely schematically. The core tube 2 is arranged concentrically with respect to a primary tube 3, so a peripheral concentric primary tube gap 4 is provided between the core tube 2 and the primary tube 3. A mixture of particulate biomass and combustion means, the primary air, is supplied to said primary tube gap by devices, not shown. Provided in the primary tube gap 4 is a swirling device 5 in the form of guide vanes which are set at about 25° relative to the longitudinal extent of the primary tube and which make the primary air flow rotate. The biomass particles then migrate in the flow direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com