Method for displacement of water from a porous and permeable formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

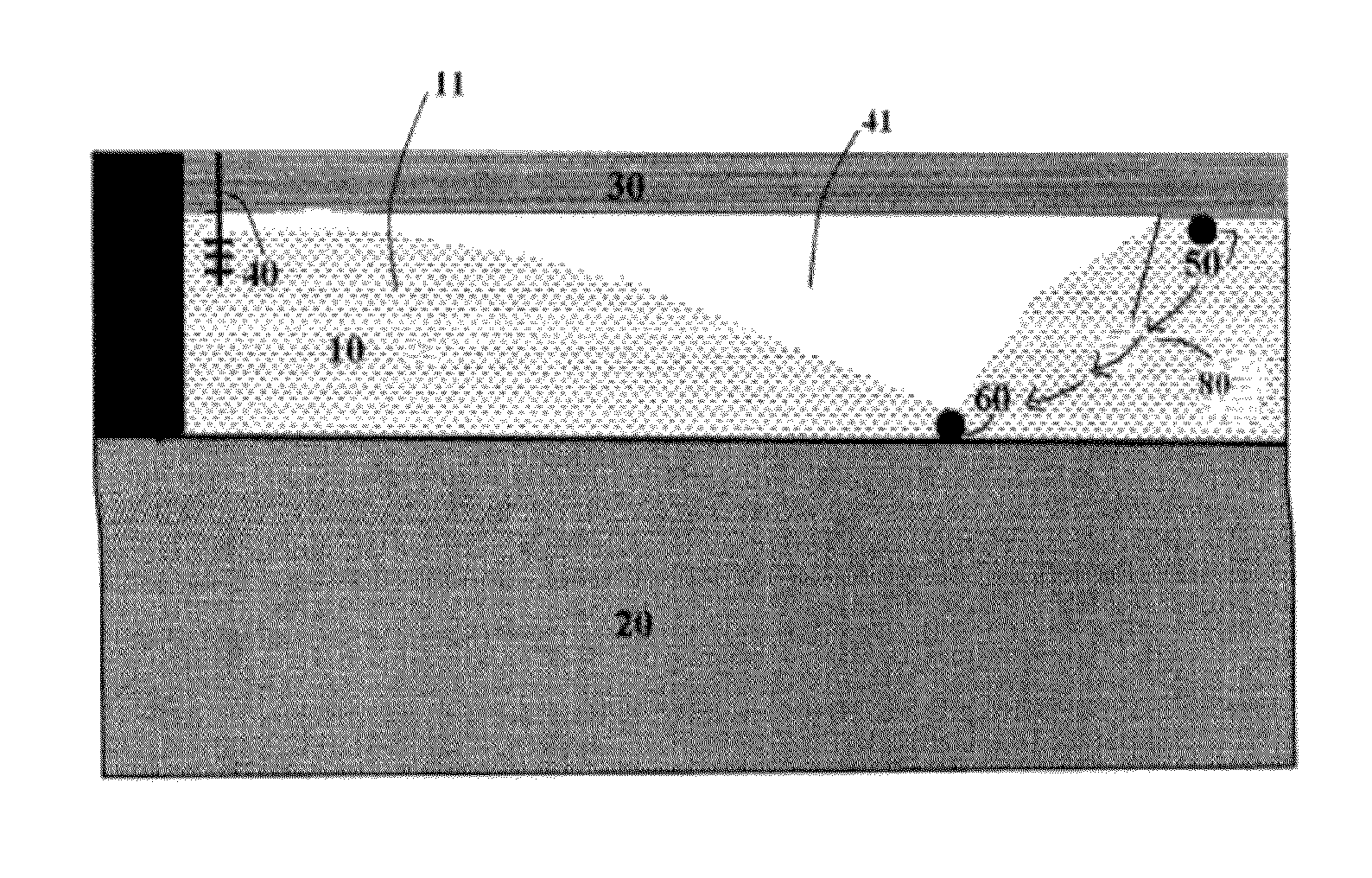

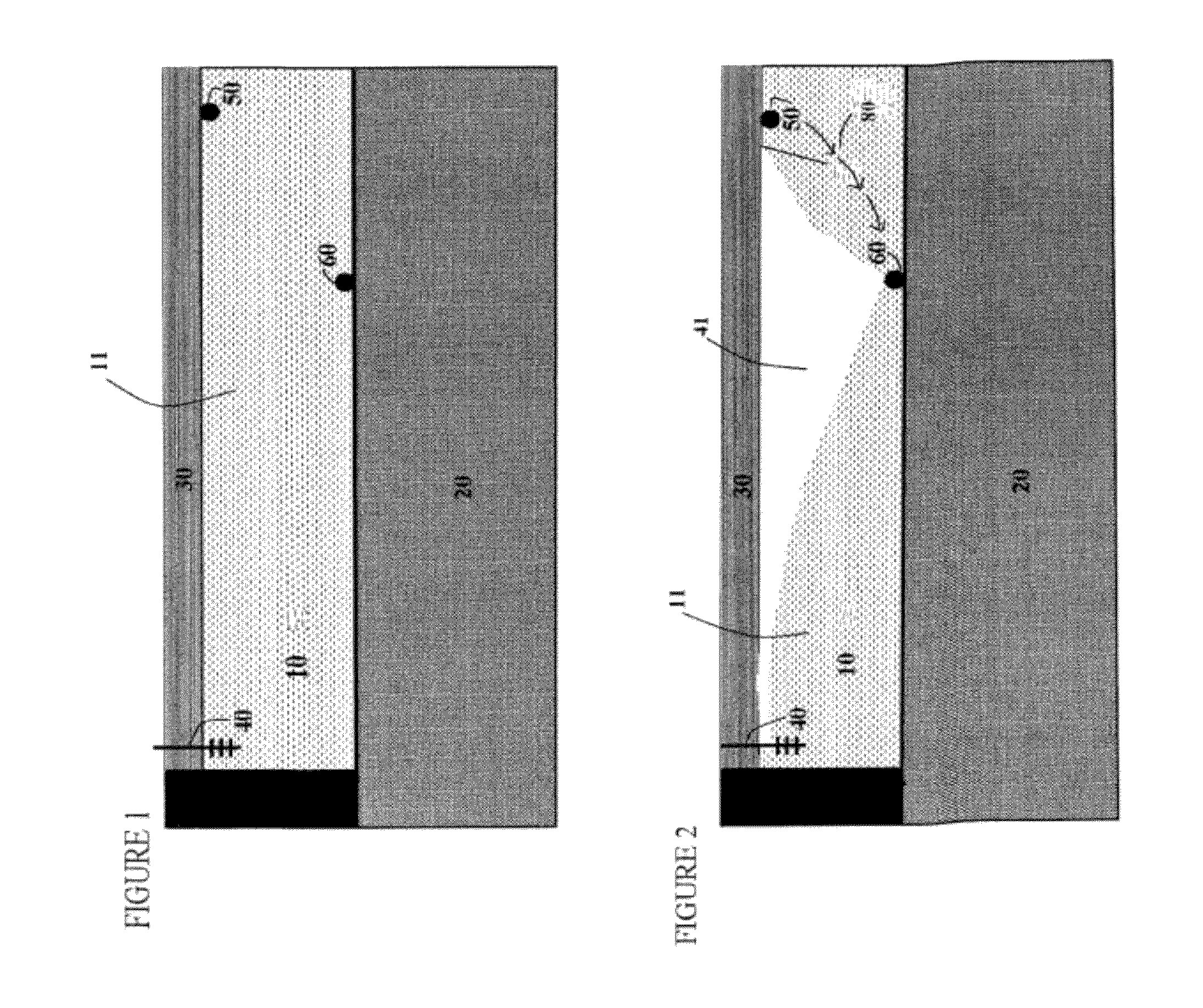

[0092]With reference to FIGS. 5 and 6, simulation results are shown in half-element form. The model accounts for two-phase immiscible flow in a porous medium, including viscosity and density differences between the gas and the water.

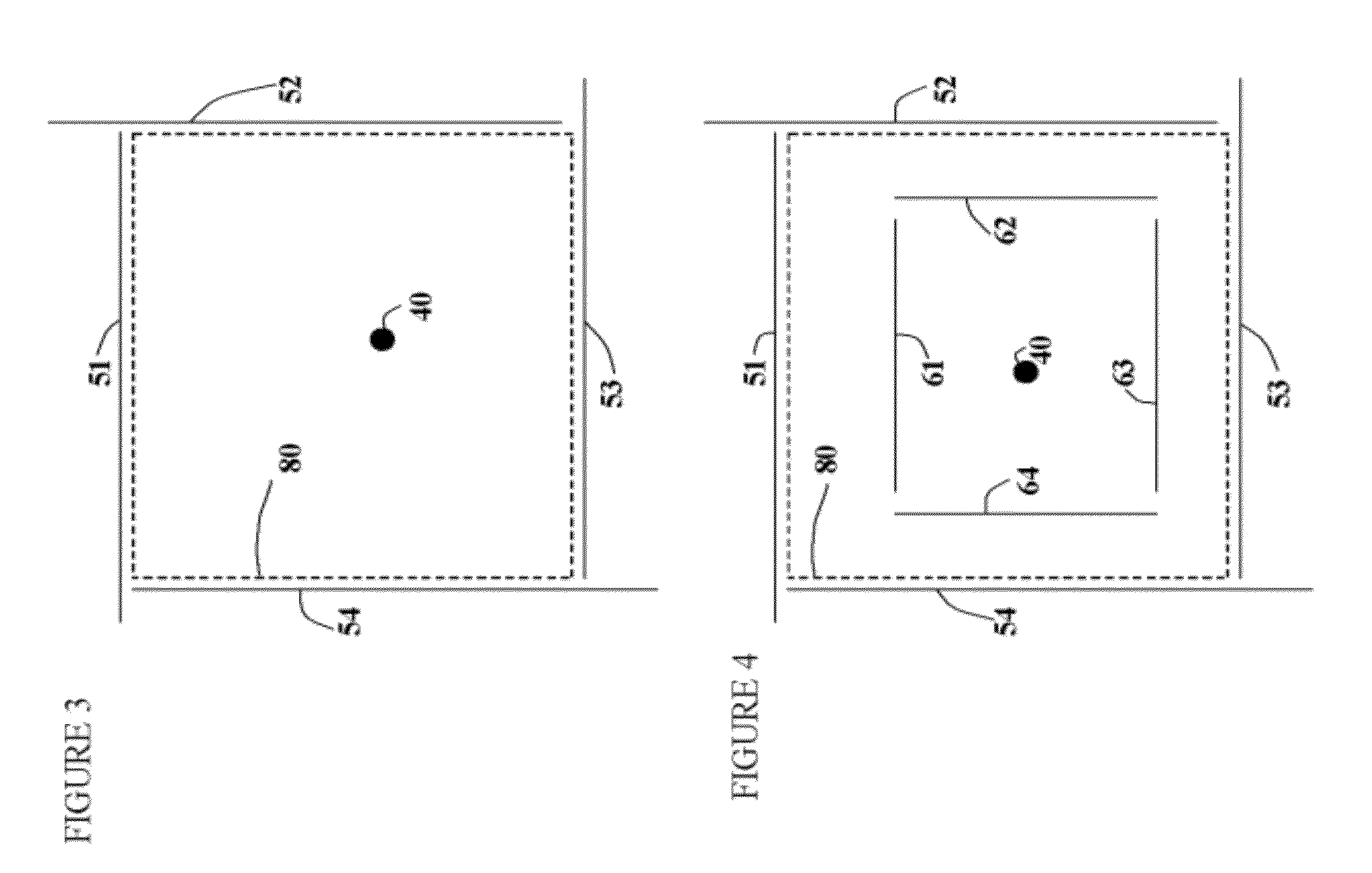

[0093]FIG. 5 illustrates the model set-up. For simplicity of illustration, by using a half-element representation, hydraulic confinement is carried out in only one direction, and a single horizontal water injection well positioned to create this hydraulic confinement or barrier is depicted. Gas injection occurs at the near face of the model, and water production at or near the base of the target region is effected using, in this illustration, two water production wells 60. In accordance with the teaching described above, the water production wells 60 are situated so that they are located within the boundaries of the target region, as defined by the imposed hydraulic barrier created through operation of the water injection well. To create this hydraulic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com