Device for adjusting rolling positions of rolling rolls constituting three-roll mandrel mill and method for manufacturing seamless pipes or tubes

a technology of rolling mills and rolling positions, which is applied in the direction of rolling mill control devices, measuring devices, manufacturing tools, etc., can solve the problems of more difficult to secure the roll-biting property of the front edge part of the pipe material in the case, more difficult to secure the circumferential length than, and achieve the effect of reducing the circumferential length of the rear edge part of the pipe or tube material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]One embodiment of the present invention will now be described with reference to the accompanying drawings as appropriate.

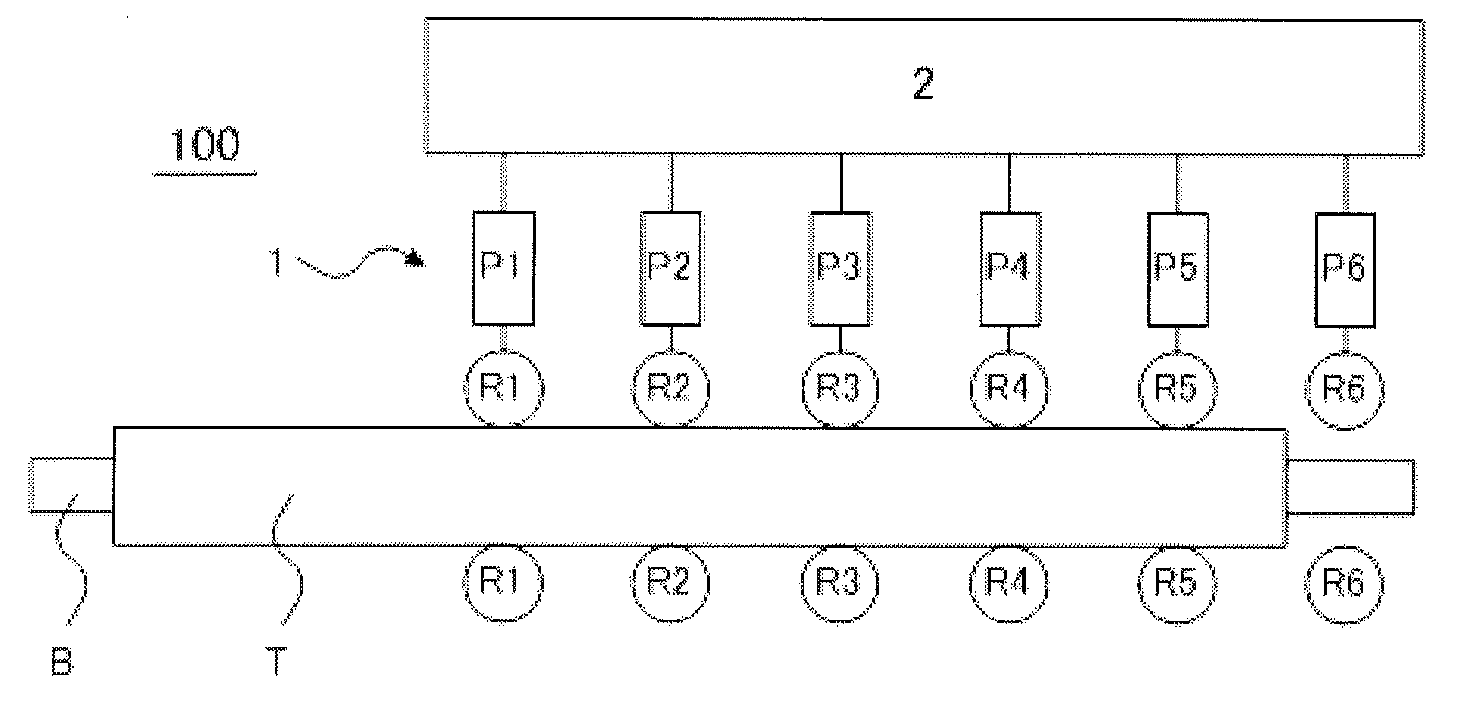

[0024]FIG. 1 is a schematic view showing a general configuration of a rolling position adjusting device for rolling rolls constituting a three-roll mandrel mill in accordance with one embodiment of the present invention.

[0025]As shown in FIG. 1, a rolling position adjusting device 100 in accordance with this embodiment is used in a three-roll mandrel mill consisting of a total of six rolling stands on each of which three rolling rolls are disposed to elongation-roll the outside surface of a pipe material T in the state in which a mandrel bar B is inserted into the pipe material T in a spit form. Describing more specifically, the rolling position adjusting device 100 in accordance with this embodiment is configured so as to be capable of adjusting the rolling positions of the rolling rolls R1 to R6 disposed on the respective rolling stands of the mandrel mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com